Full-automatic cooker

A rice cooking device and fully automated technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of inability to produce in large quantities, rice deterioration and taste, and independent cleaning process, etc., achieving low manufacturing cost and simplified machinery Structure, easy to promote the effect of industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

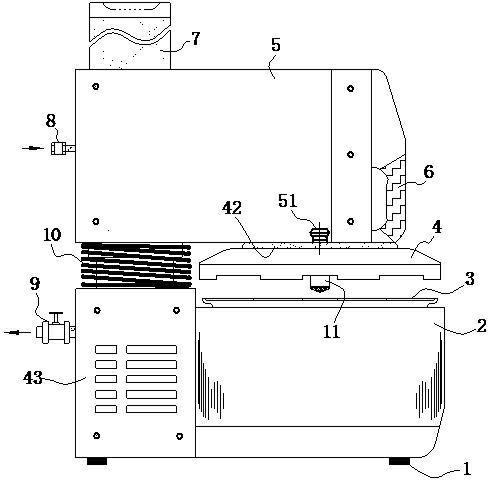

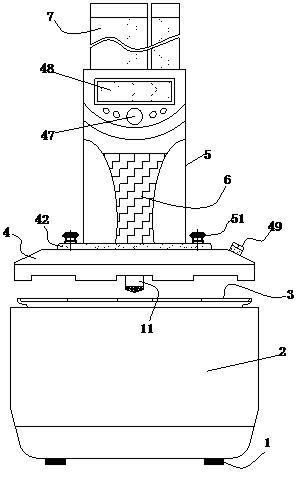

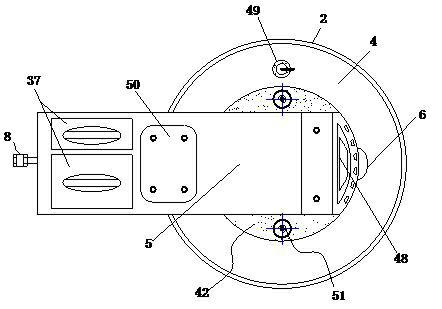

[0033] The mechanism and structural arrangement of the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0034] see figure 1 and Figure 4 Among them, as the preferred first embodiment of the present invention, it represents the application of straight cover type structure. The fully automatic rice cooking device is mainly composed of the upper body 5 and the lower body 43. The upper body 5 and the lower body 43 are connected through the inner shaft sleeve 38 and The outer shaft sleeve 39 is connected into one body, forming the upper end body 5 to rotate left and right, while the upper end body 5 can also move up and down, and a spring 10 is also arranged between the inner shaft sleeve 38 and the outer shaft sleeve 39. The arrangement purpose of the spring 10 is The weight of the upper body is reduced, so that it can turn left and right or move up and down more flexibly.

[0035] Figure 2-5 Among them, it m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com