Automatic production line for shells of electrical appliances

A technology for automatic production lines and electrical enclosures, applied to other manufacturing equipment/tools, metal processing, metal processing equipment, etc., can solve the problems of unsuitable sheet metal boxes, etc., to reduce manual operations, improve quality, and increase production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

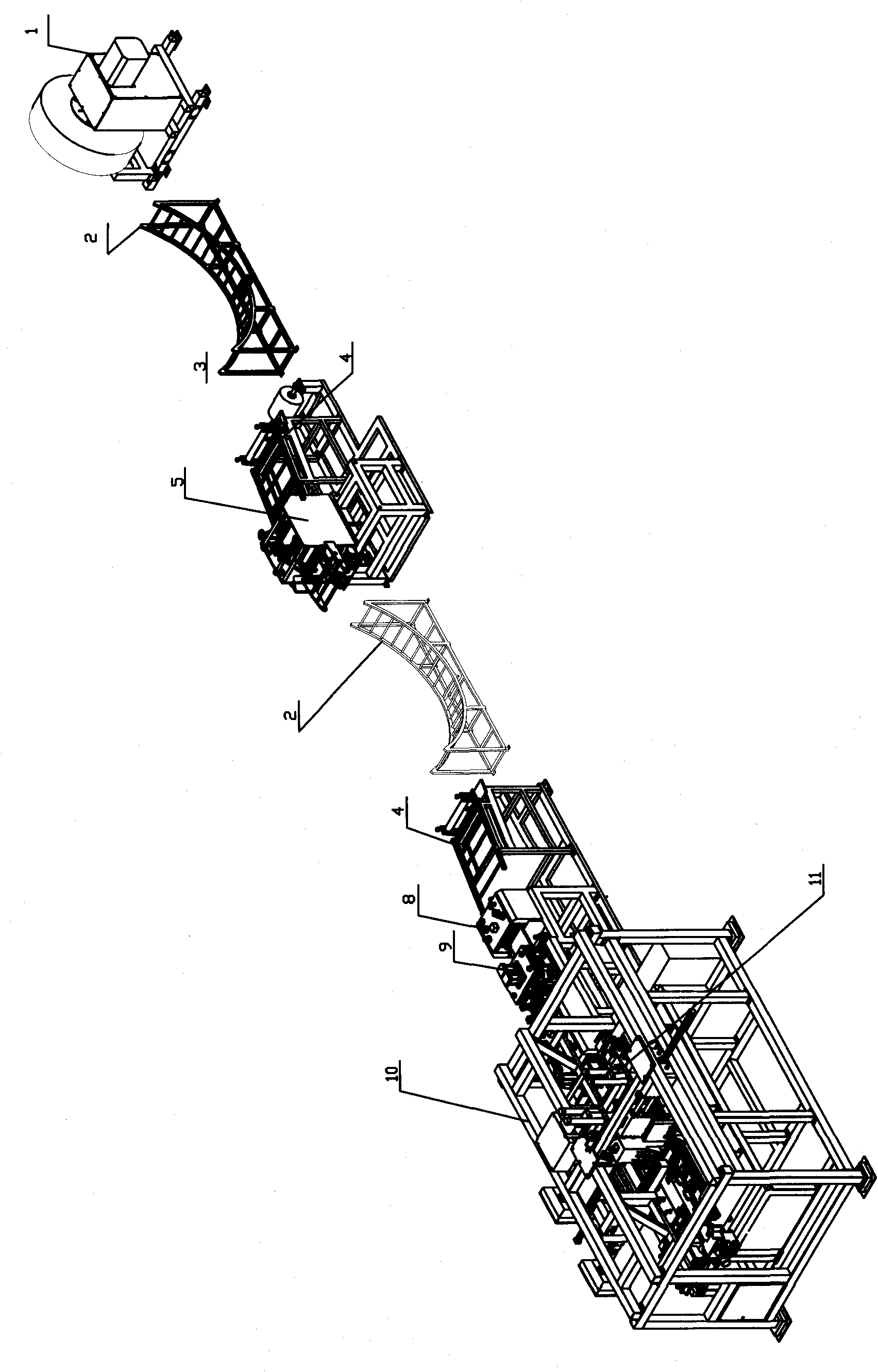

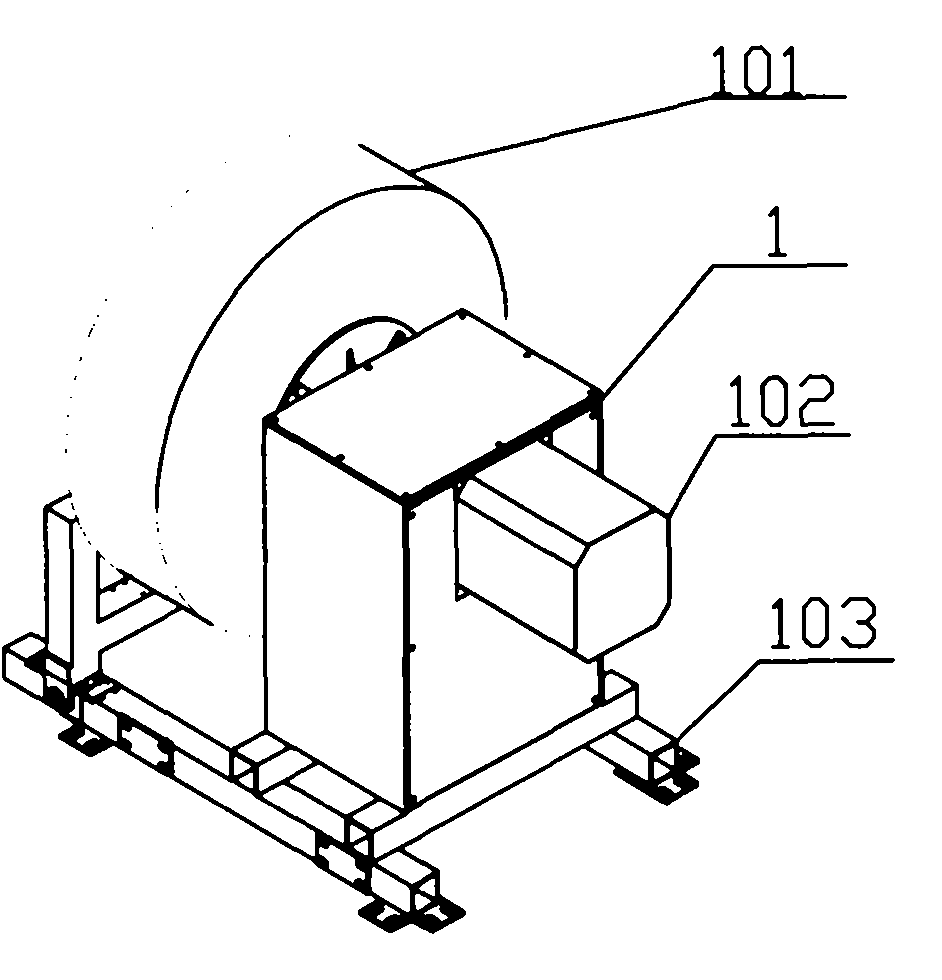

[0029] As shown in the figure, an automatic production line for electric appliance shells is composed of a feeding frame 1 controlled by a computer, a trimming machine 5 and a forming machine 10. The support shaft 101, the support shaft 101 is driven by the hydraulic motor 102 to rotate, and the support shaft 101 is also provided with a regulator for adjusting its diameter;

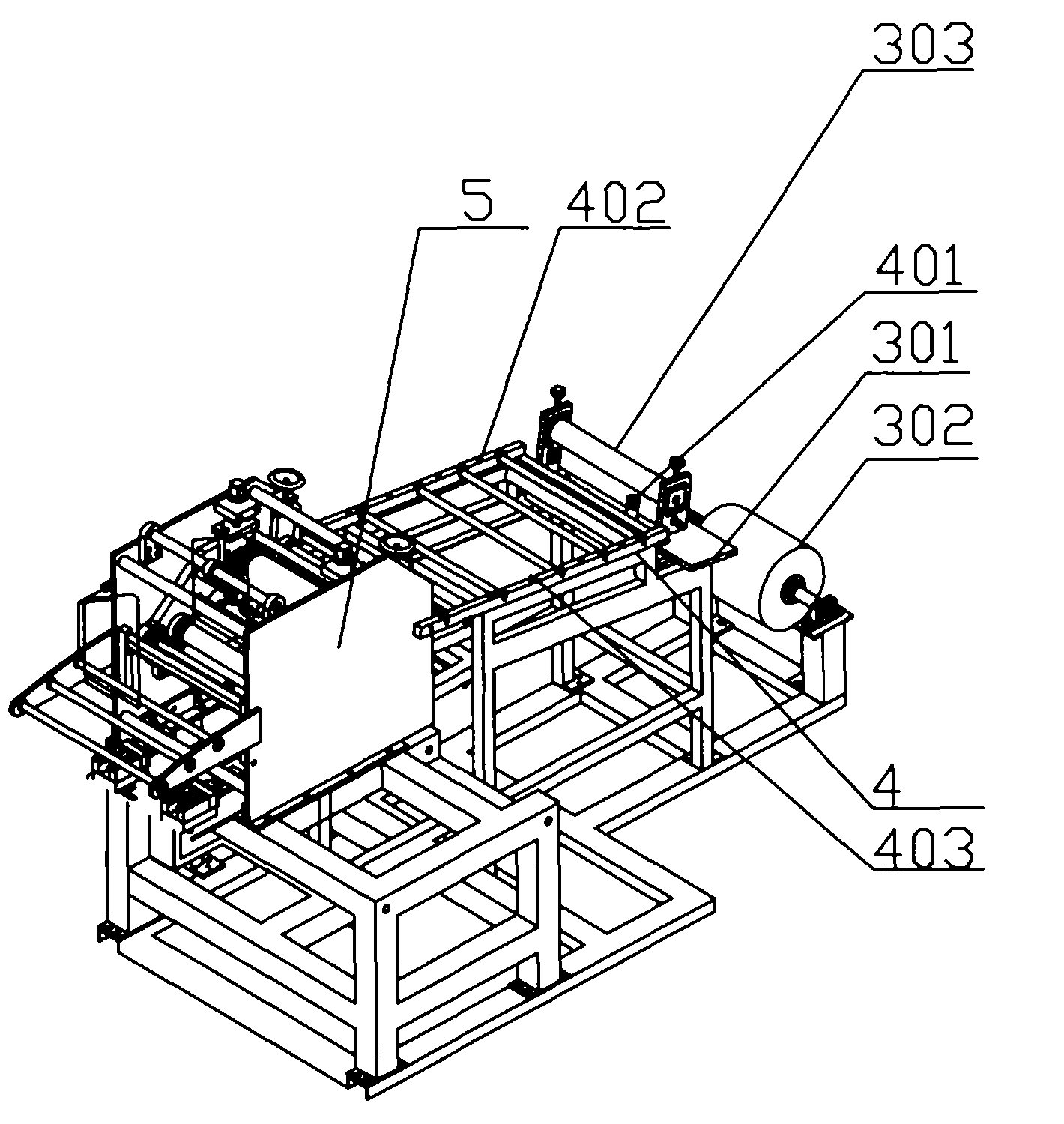

[0030] The trimming machine 5 is provided with a frame, and a drive motor is installed inside to drive a feeding roller and a trimming knife, and a film releasing shaft 302 is also arranged before the feeding roller, and the two ends of the film releasing shaft 302 are supported on the frame;

[0031] Described forming machine 10 is provided with machine platform, is provided with leveling area 8, punching area 9 and molding area 11 on the machine platform, and this leveling area 8 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com