Rotary anti-leakage grinder

A grinder and rotary technology, which is applied in the field of grinders, can solve the problems of emotions affecting dining, grinding labor, leakage, etc., and achieve the effects of increasing dining interest, smooth flow, and hygienic use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

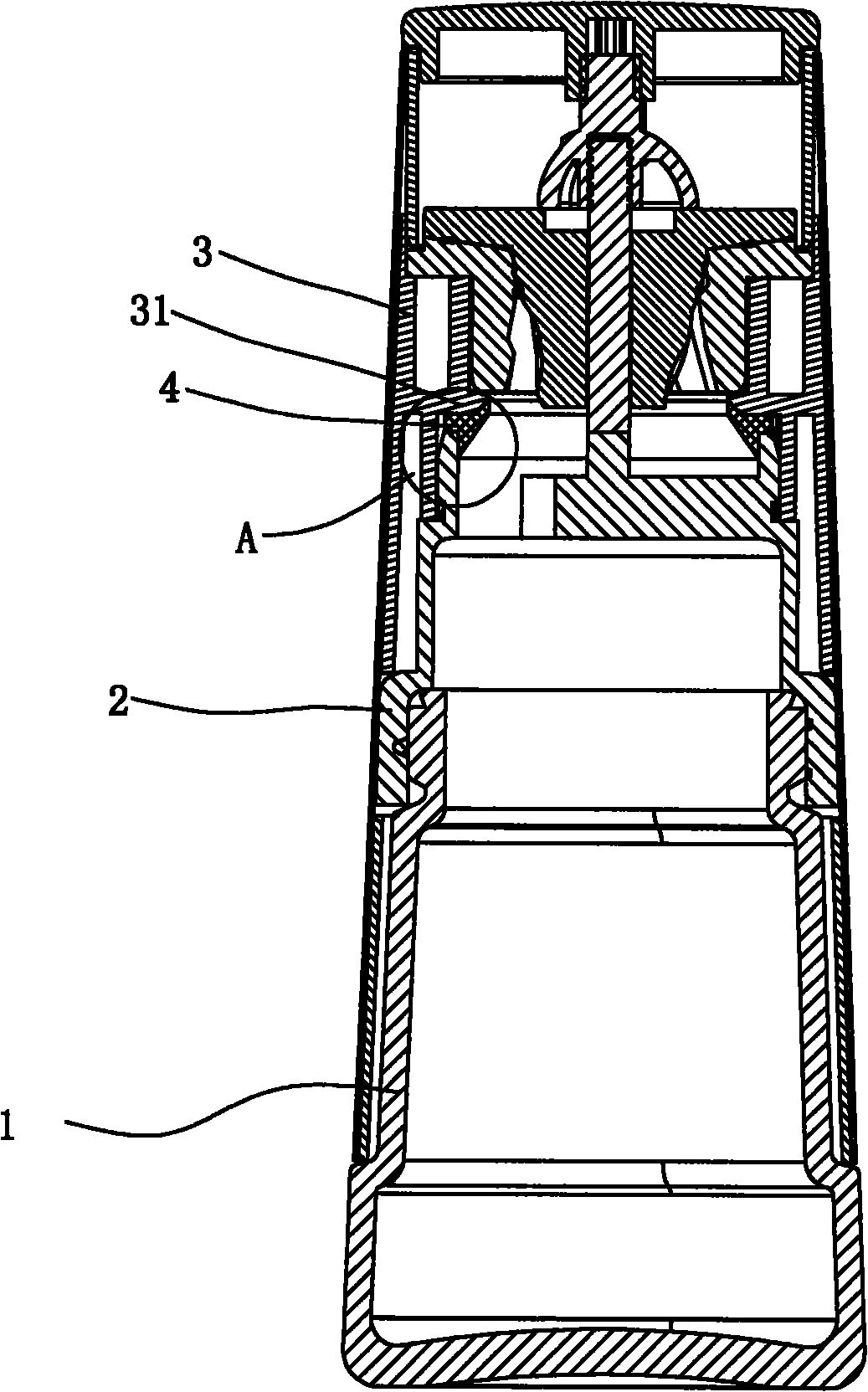

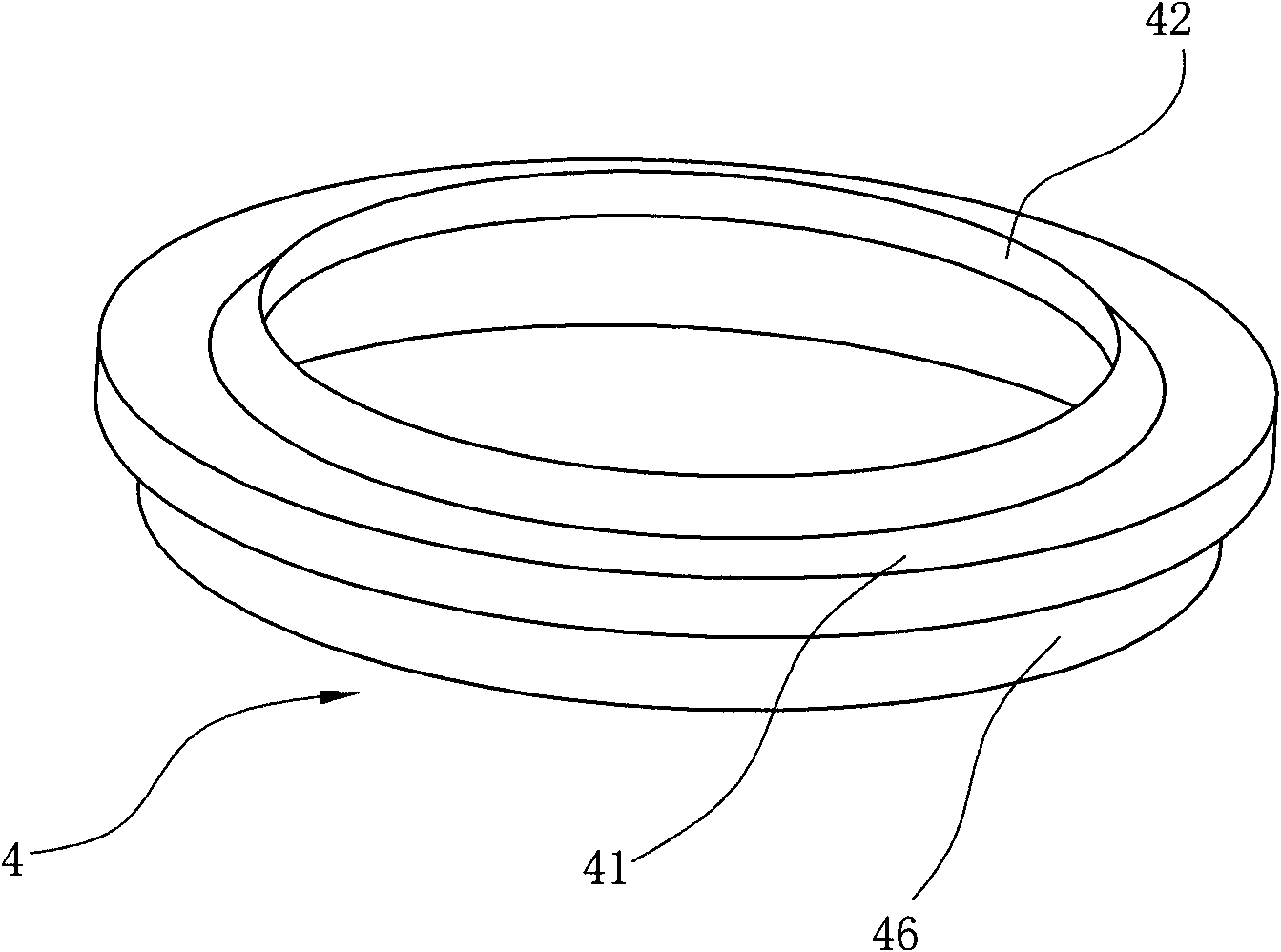

[0016] Such as Figure 1 to Figure 5 Shown, this rotary leak-proof grinder includes:

[0017] The bottle body 1, when the grinder is not working, the bottle body 1 is located below the grinder, and is used to hold the seasoning to be ground, and the bottle mouth is provided with an external thread.

[0018] One end of the adapter tube 2 is screwed on the external thread of the bottle body 1, and the other end is used to connect the grinding head 3 described below.

[0019] Grinding head 3, when the grinder is not working, the grinding head 3 is located above the grinder; a grinding mechanism (not shown) for grinding seasoning is provided in it, and a seasoning outlet (not shown) is provided on its top , the lower part of which is sleeved on the other end of the adapter cylinder 2, and there is a matching gap 33 between the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com