Positive pressure pneumatic conveying system and method

A pneumatic conveying system and pneumatic conveying technology, applied to conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as increased air consumption, poor adaptability to changes, and decreased conveying output, and achieve the effect of improving conveying force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

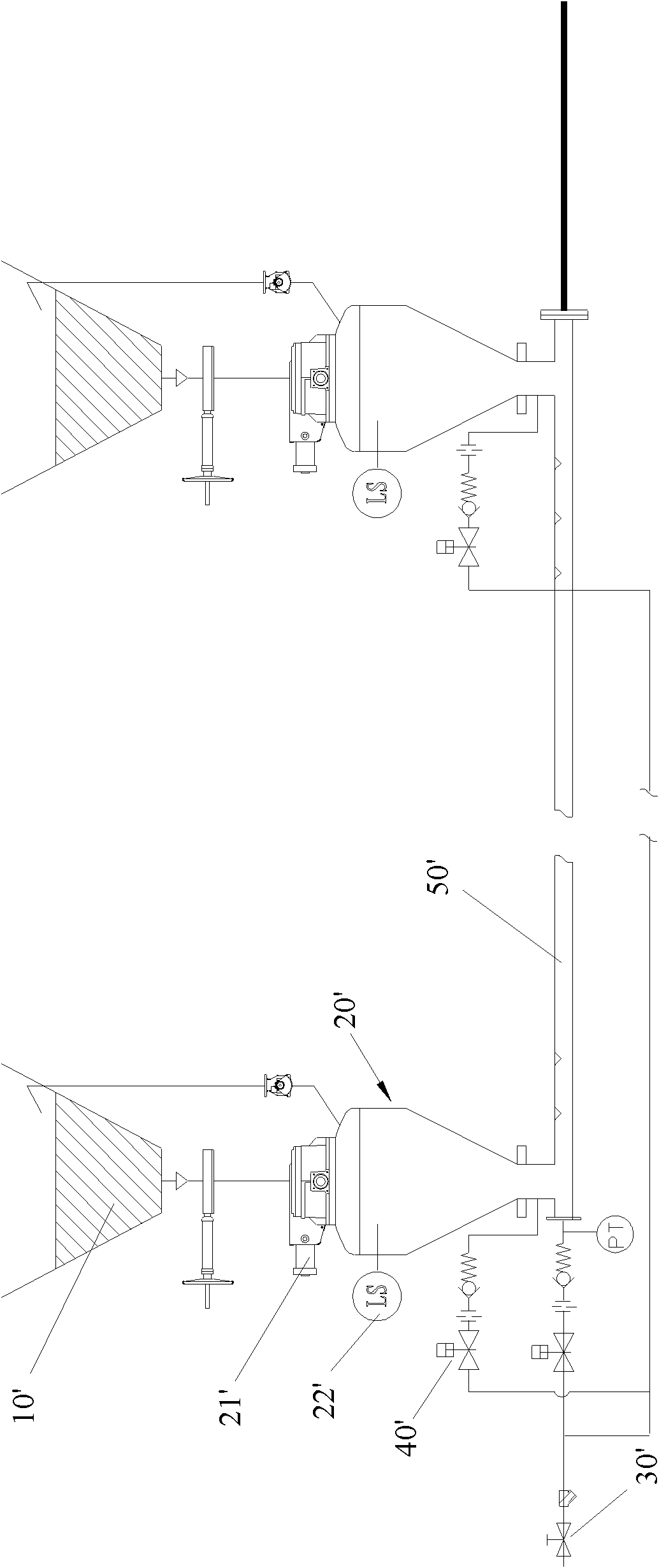

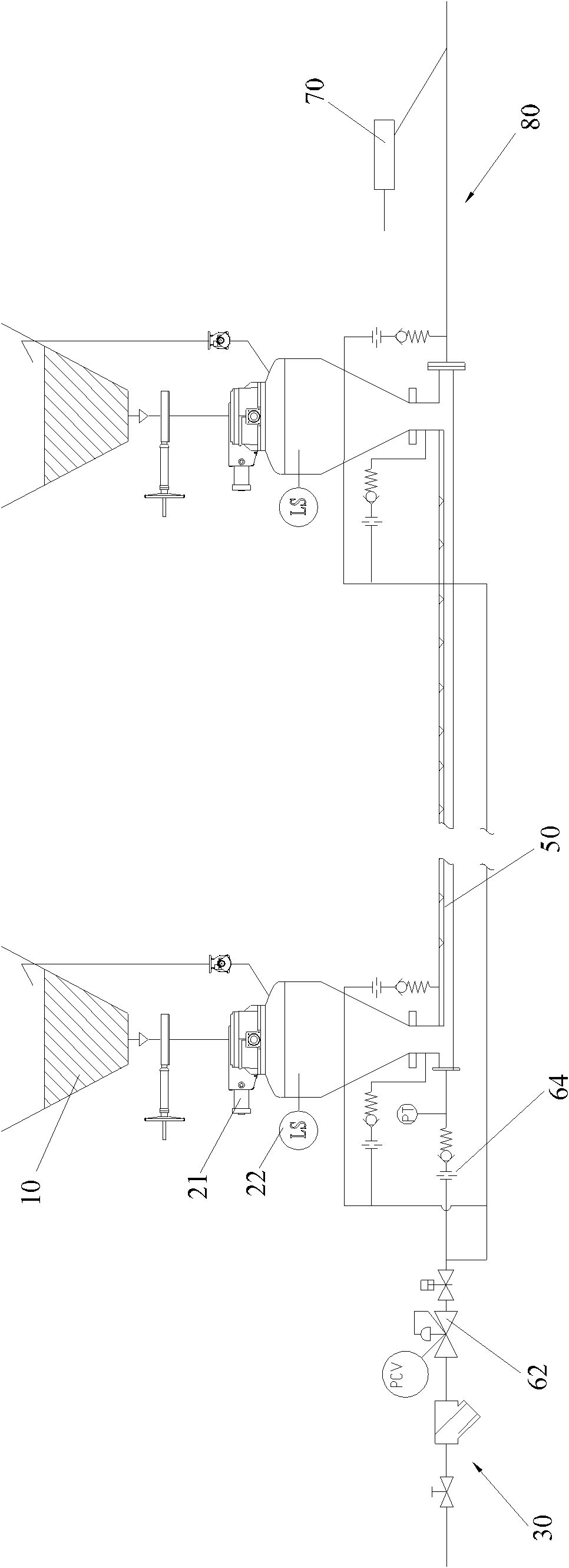

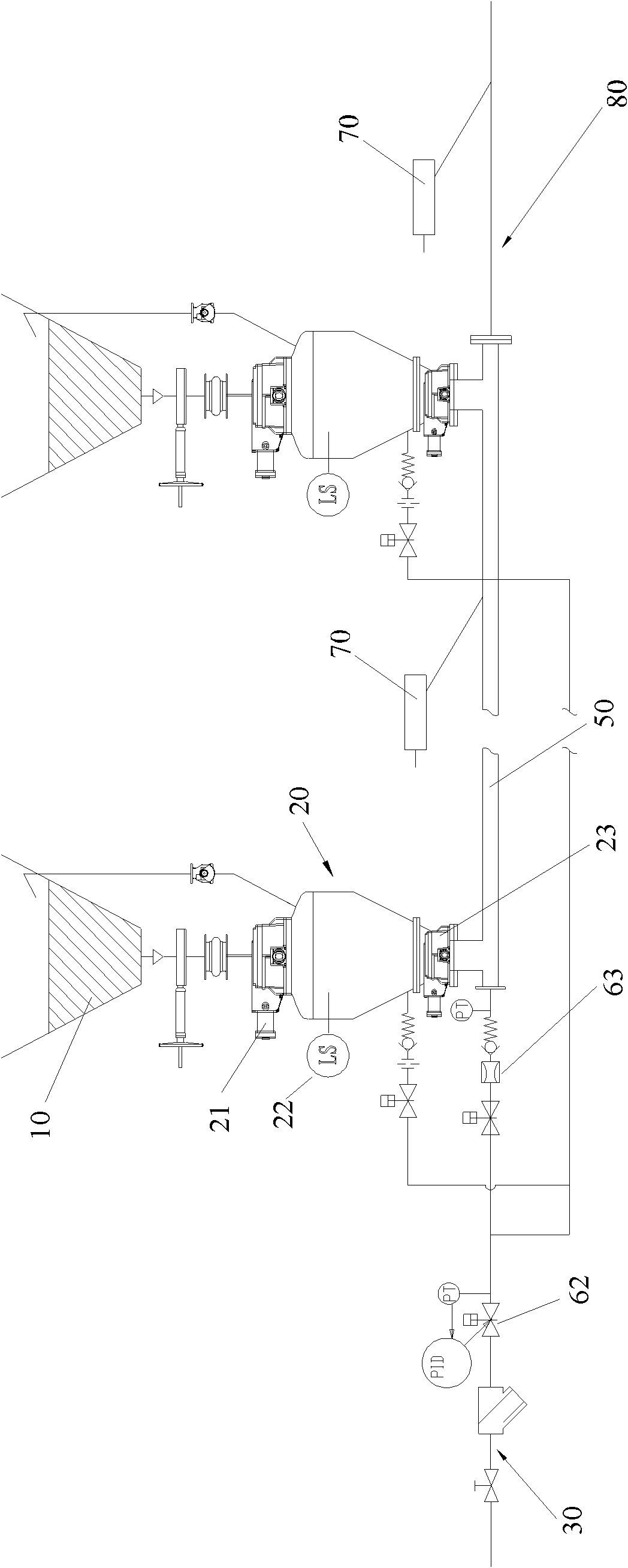

[0025] According to the positive pressure pneumatic conveying system of the present invention, such as figure 2 As shown in FIG. 5 , the main air intake pipeline 30 is included, and its first end communicates with the first compressed air source; the delivery pipeline 50 has a first end communicated with the main air intake pipeline 30; a plurality of warehouse pumps 20, The lower ends of multiple warehouse pumps 20 are connected with the conveying pipeline 50; an air volume regulating device is also included, and the air volume regulating device includes: a pressure regulating valve 62, which is arranged on the main air intake pipe 30; Downstream of the pressure regulating valve 62 on the gas pipeline 30, the gas flow through it is adjusted according to the post-valve pressure value of the pressure regulating valve 62; the pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com