Method for treating constructed residual mud

A technology for the specific gravity of mud and mud, applied in the fields of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of slow transportation, increased cost, slow construction period, etc., to reduce the amount of treatment , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A method of processing construction surplus mud of the present invention, comprises the following steps:

[0012] (1), put cement into the remaining mud after construction and stir;

[0013] (2) After the mud settles, drain the surface water;

[0014] (3), transport the remaining sludge out for disposal.

[0015] In the present invention, cement is put into the mud, and after being stirred evenly, the surface clear water is separated through cement and soil, sand, and gravel particles in the mud to bond and settle, and the surface clear water can be directly pumped and drained to quickly and effectively remove the remaining The sludge is loaded and transported out, thereby reducing the amount of mud treatment, reducing the total cost of mud treatment, and effectively preventing the environment from being affected by the mud.

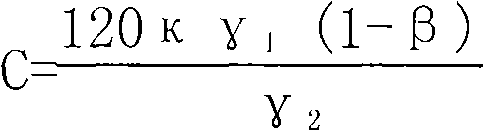

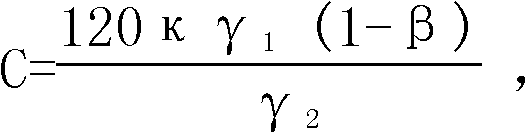

[0016] As a preferred embodiment, before step (1), measure the specific gravity, sand content, and colloidal index of the remaining mud during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com