Running mechanism for arched bridge inspection car

A technology of running mechanism and arch bridge, which is applied in the direction of bridges, bridge parts, bridge construction, etc., to achieve the effect of simple operation, fast operation speed and low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

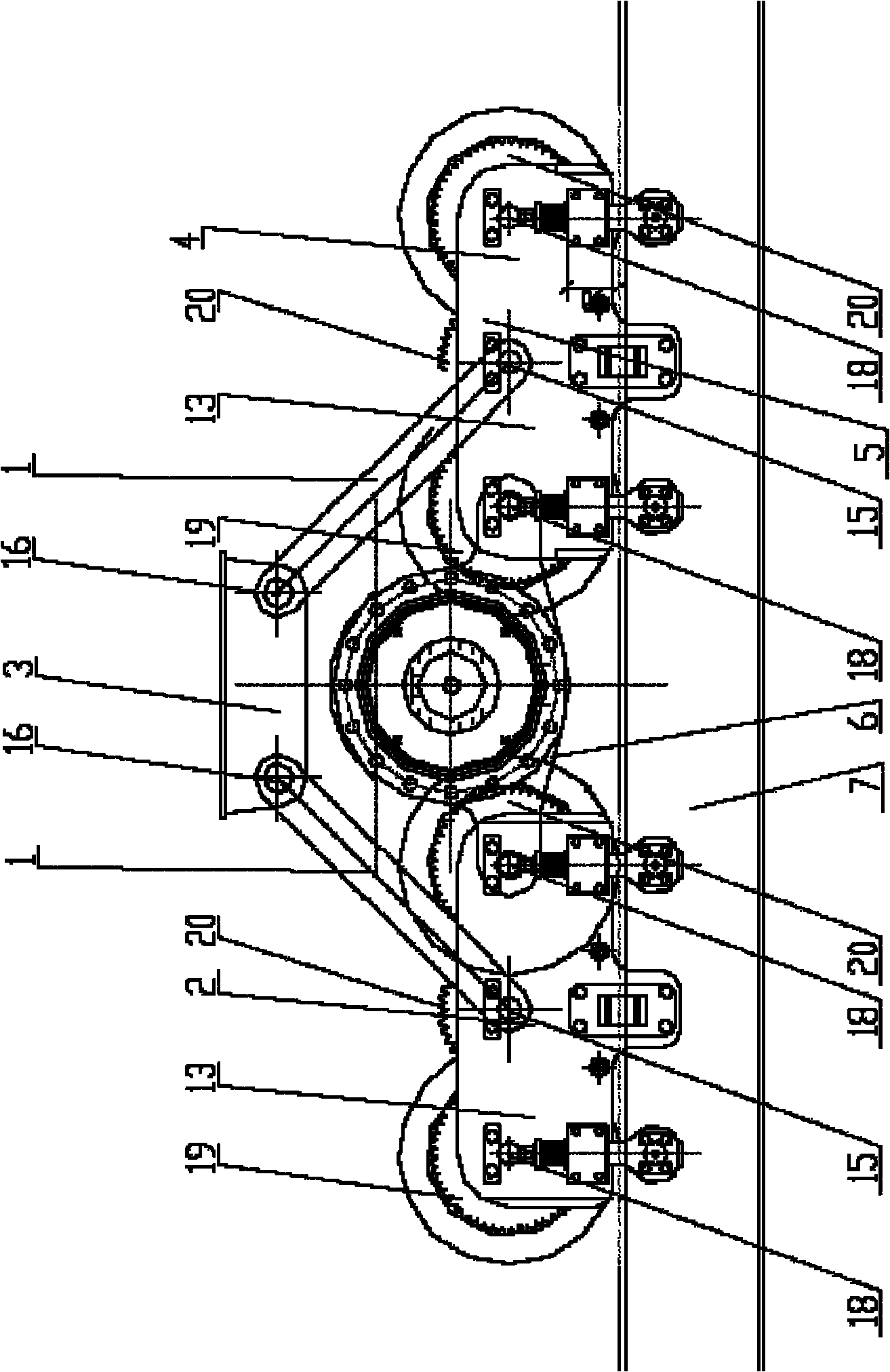

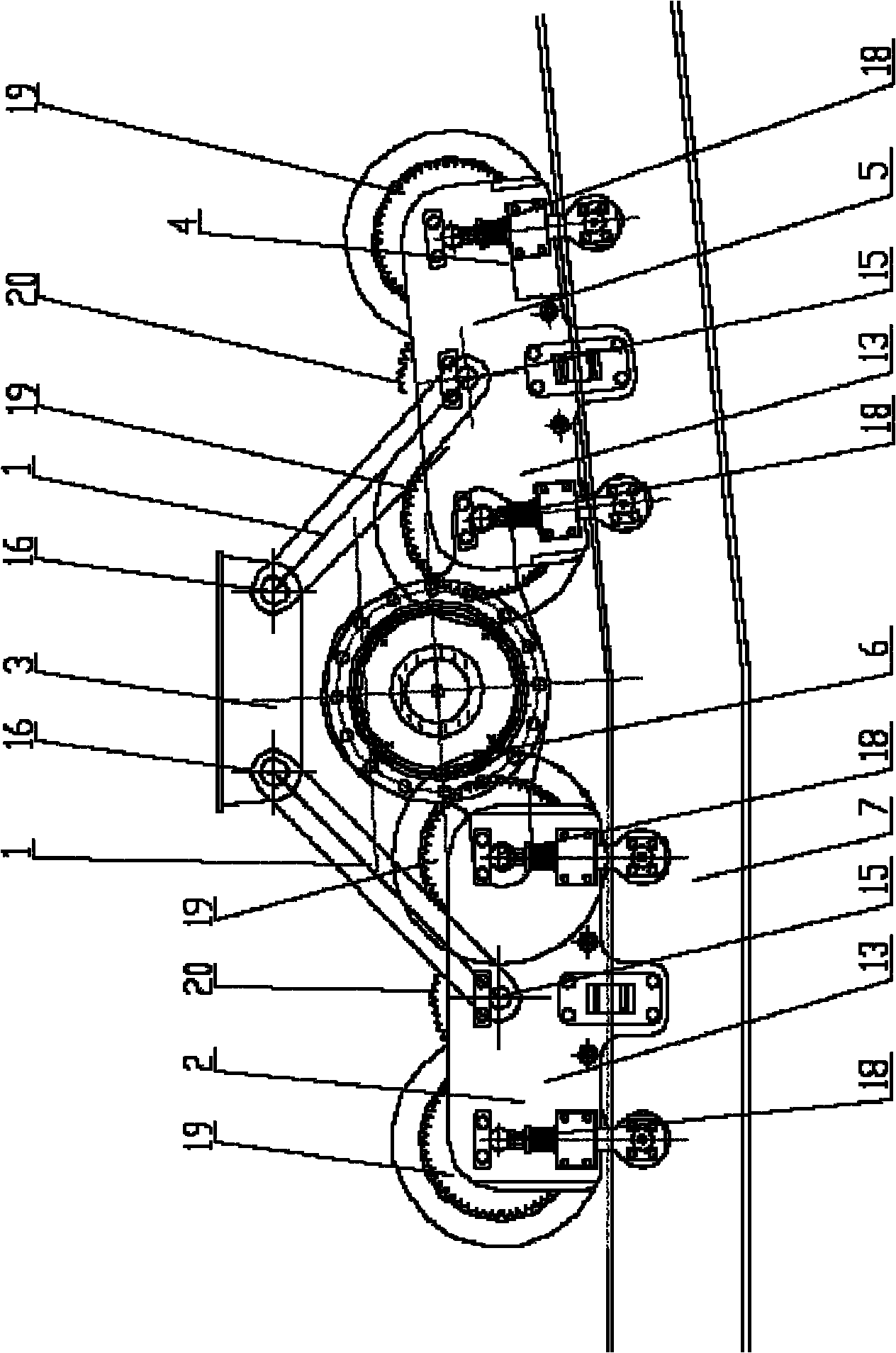

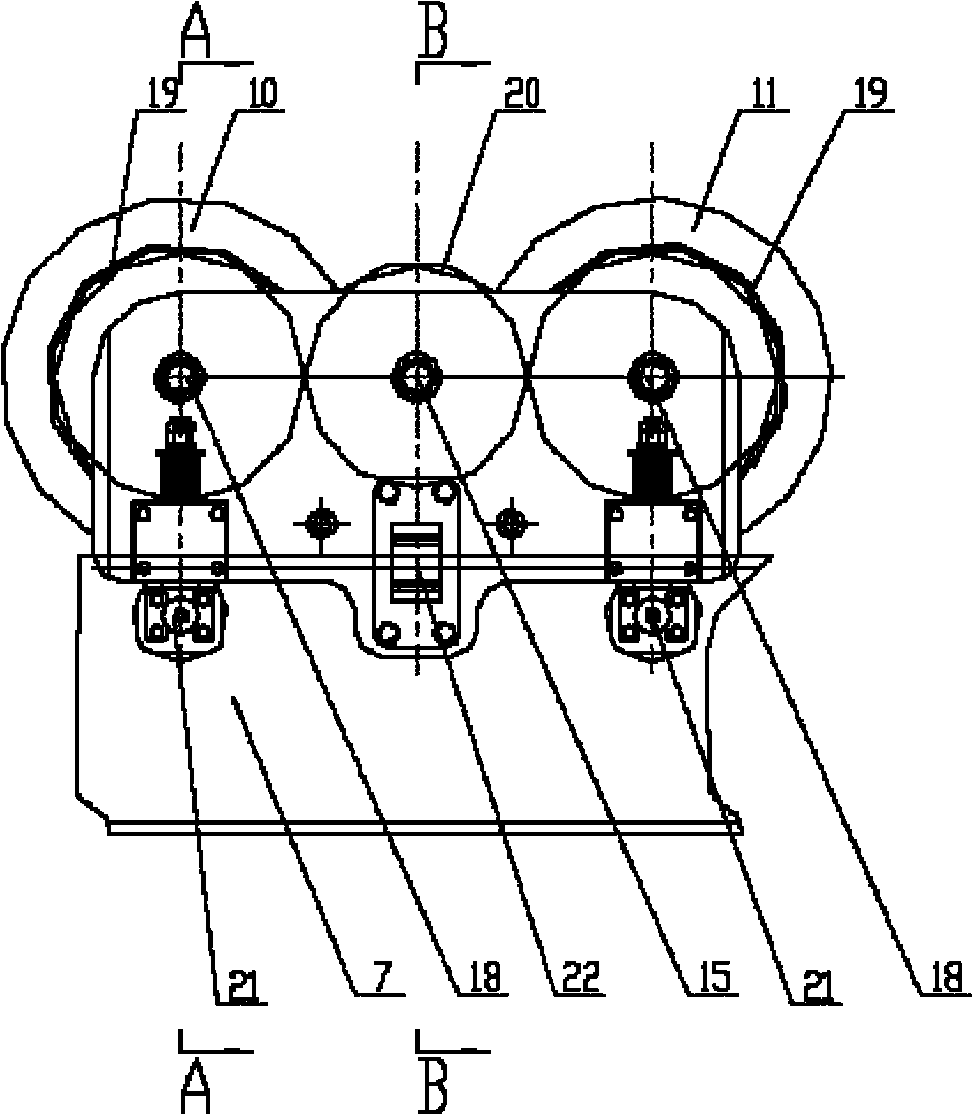

[0019] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

[0020] The front traveling wheel assembly 2 and the rear traveling wheel assembly 4 on the traveling mechanism of this design have the same structure, and the wheels 17 of the front and rear wheel sets 10, 11 are fixedly connected to the gear 19 by bolts respectively, and then loaded into the working shaft 18, the middle part Working gear 20 is equipped with working shaft 15, the gear 19 on the front wheel group 10 and the gear 19 on the rear wheel group 11 mesh with the middle working gear 20 therebetween, then the left support plate 13 and the right support plate 14 are respectively Set on the two ends of the working shaft 18 of the front and rear wheel groups and the working shaft 15 of the middle working gear 20, fasten them with round nuts, and then install the left and right side wheel groups 22, 12 on the left and right support plates 13 respectively , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com