Torque amplifying device

A technology for amplifying devices and housings, which is applied to fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of increased manufacturing costs, complicated processes, and high manufacturing costs, and achieve volume and weight reduction, and lower manufacturing costs. The effect of cost, adjustment and maintenance convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

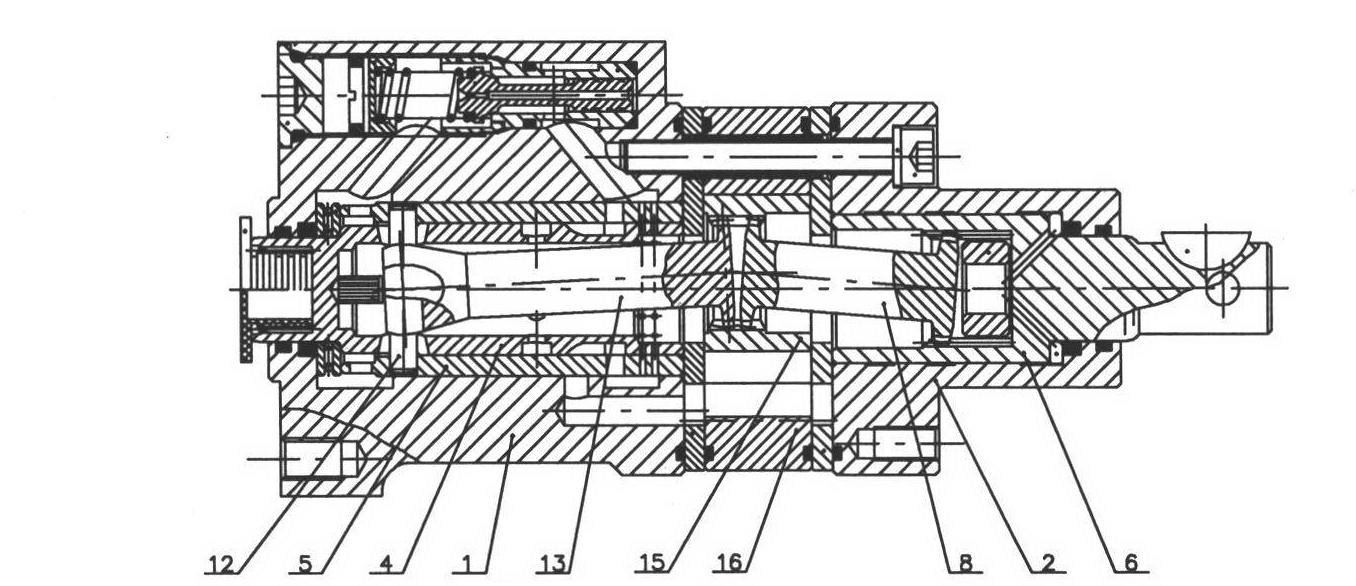

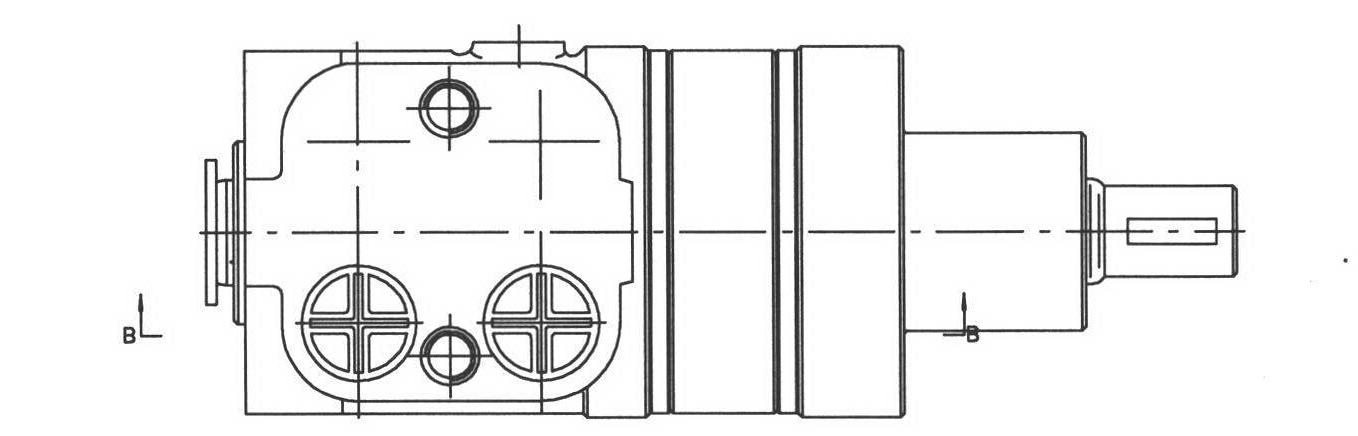

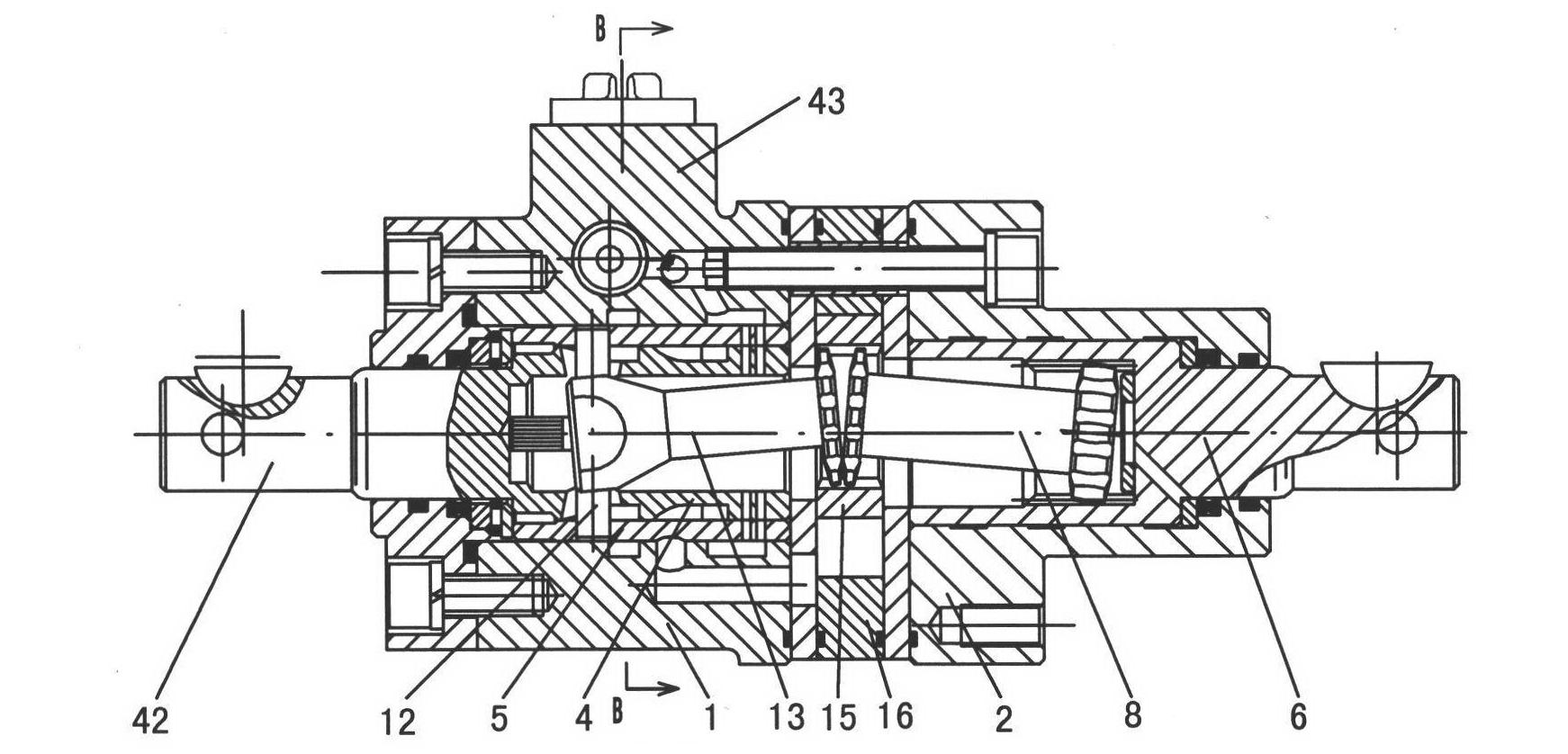

[0015] The torque amplification device of this embodiment is as Figure 2-Figure 5 As shown, there is a casing composed of a casing 1, a stator 16 and a rear cover 2 fixedly connected in sequence along the main axis direction, and two spacers are respectively installed at both ends of the stator 16. The casing 1 is provided with a spool cover 5 for the input spool 4, and the input spool 4 is connected with the input shaft 42 protruding from the casing 1 as a whole. The rotor 15 forming a cycloidal pin-wheel pair is housed in the stator 16 . The output shaft 6 is supported inside the rear cover 2 . The inner hole of the rotor 15 is engaged with the opposite ends of the input linkage shaft 13 and the output linkage shaft 8 through internal splines, and the other end of the input linkage shaft 13 is connected with the valve core sleeve 5 through the dial pin 12, and the other end of the output linkage shaft 8 One end is transmission-connected with the output shaft 6 through an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com