Tensioning structure of transmission chain of pneumatic tyred roller and adjusting method of tensioning structure

A technology for tire rollers and transmission chains, applied in the directions of transmissions, belts/chains/gears, mechanical equipment, etc., can solve the problems of high torque, thread seizure, cumbersome process, etc., and achieve the effect of simple structure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

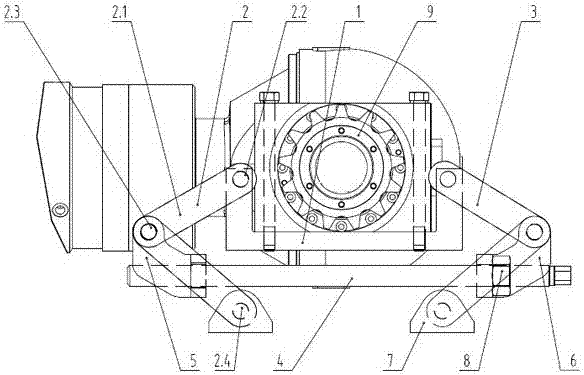

[0022] see figure 1 , a tire roller drive chain tensioning structure related to the present invention, said structure includes a sprocket 9 installed on the drive axle support 1;

[0023] A screw 4 is horizontally arranged below the drive axle support 1, and the left and right ends of the screw 4 are respectively screwed with a guiding left-handed thread block 5 and a guiding right-handed thread block 6,

[0024] The left connecting rod assembly 2 includes two connecting rods 2.1, the top of the upper connecting rod 2.1 is hinged to the drive axle support 1 at the hinge point 1 2.2, and the bottom of the connecting rod 2.1 located at the bottom is hinged at the hinge point 3 with the frame 7 2.4, the bottom of the upper connecting rod 2.1 and the top of the lower connecting rod 2.1 are hinged to the guide left-handed threaded block 5 through hinge point 2 2.3;

[0025] The right connecting rod assembly 3 includes two connecting rods, the top of the connecting rod at the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com