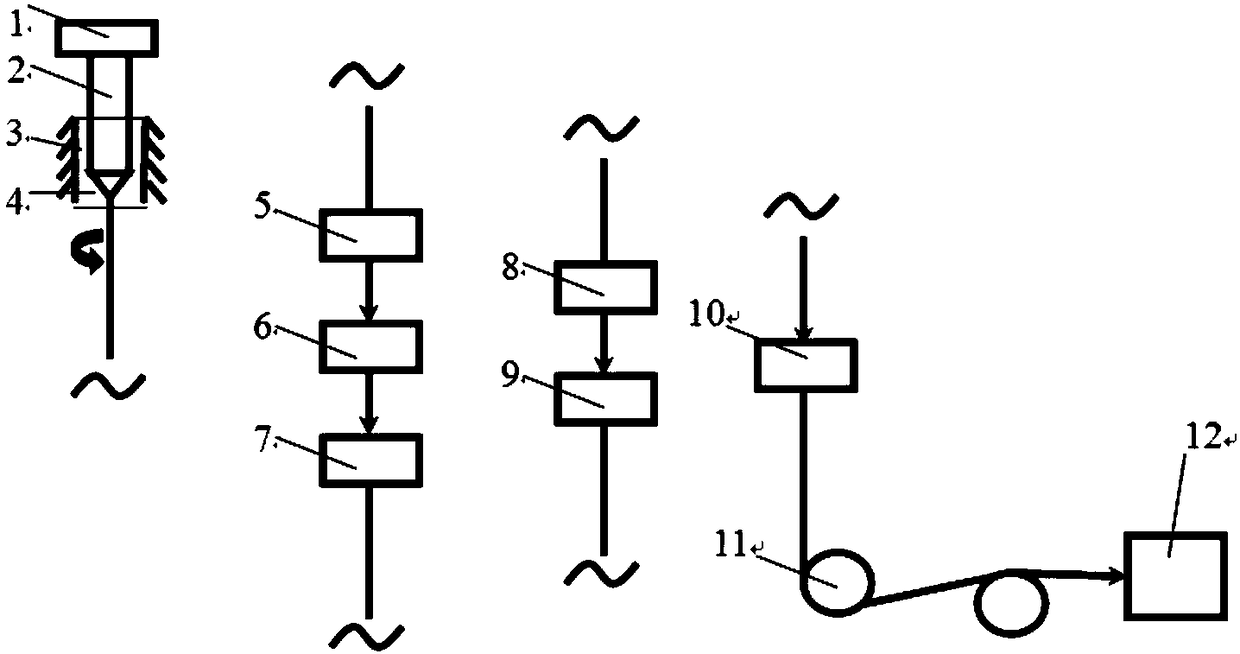

Optical fiber twisting equipment

An optical fiber and uniform technology, applied in the field of optical fiber twisting device, can solve the problems of economic loss, complex and bulky twisting equipment, etc., and achieve the effect of simple structure, easy adjustment and maintenance, and stable control of polarization mode dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

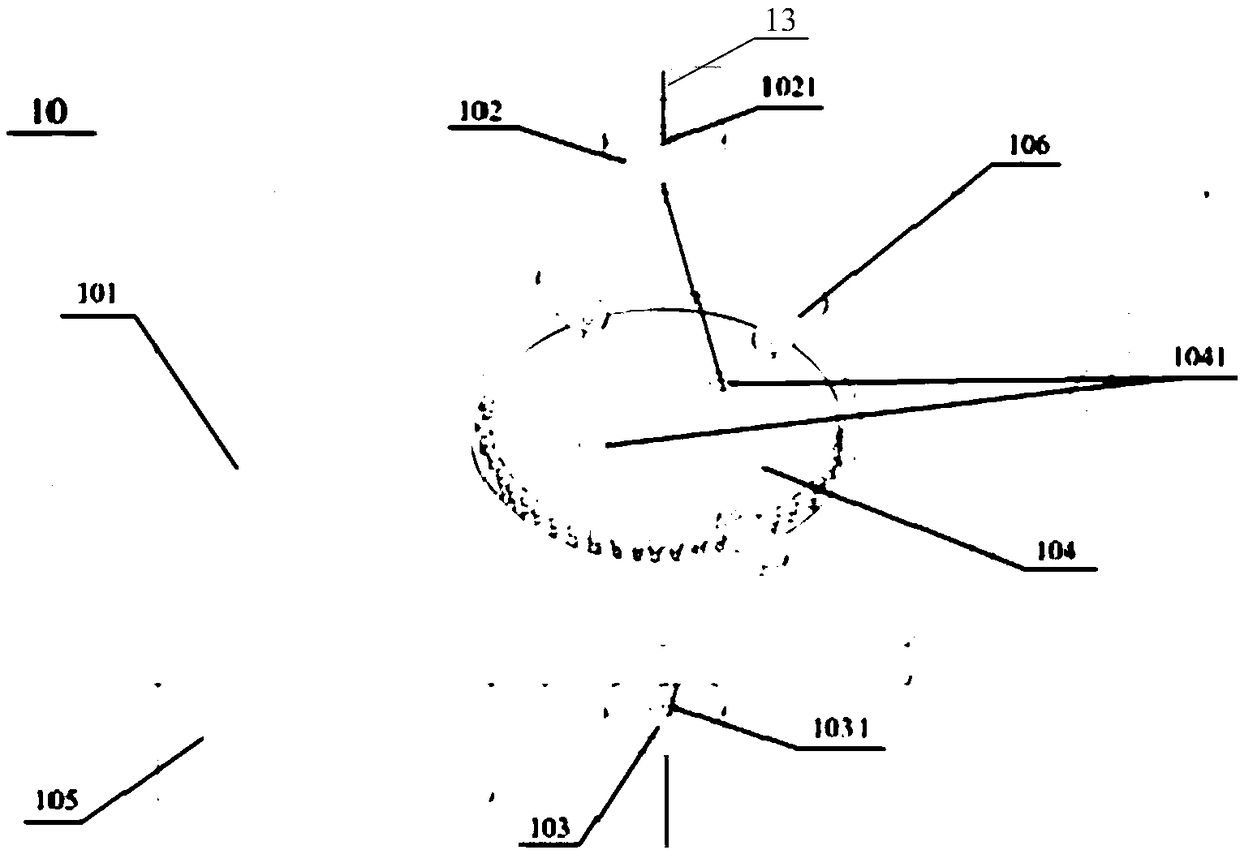

[0046] refer to figure 2 as shown, figure 2 It is a schematic diagram of a three-dimensional structure of an optical fiber twisting device provided by an embodiment of the present invention. The fiber twisting device 10 includes a base frame 101 , a first limiting member 102 , a second limiting member 103 , a rotating disk 104 and a driving assembly 105 .

[0047] Specifically, the base frame 101 has a cylindrical hollow structure, the rotating disk 104 is erected on the top of the hollow structure, and the first limiting member 102 and the second limiting member 103 are symmetrically arranged on the upper and lower sides of the rotating disk 104; The distance between the limiting member 102 , the second limiting member 103 and the rotating disk 104 can be adjusted. Wherein, the first limiting member 102 and the second limiting member 103 can be respectively fixed on a supporting structure (not shown), and the supporting structure can be fixed on the base frame 101 .

[0...

Embodiment 2

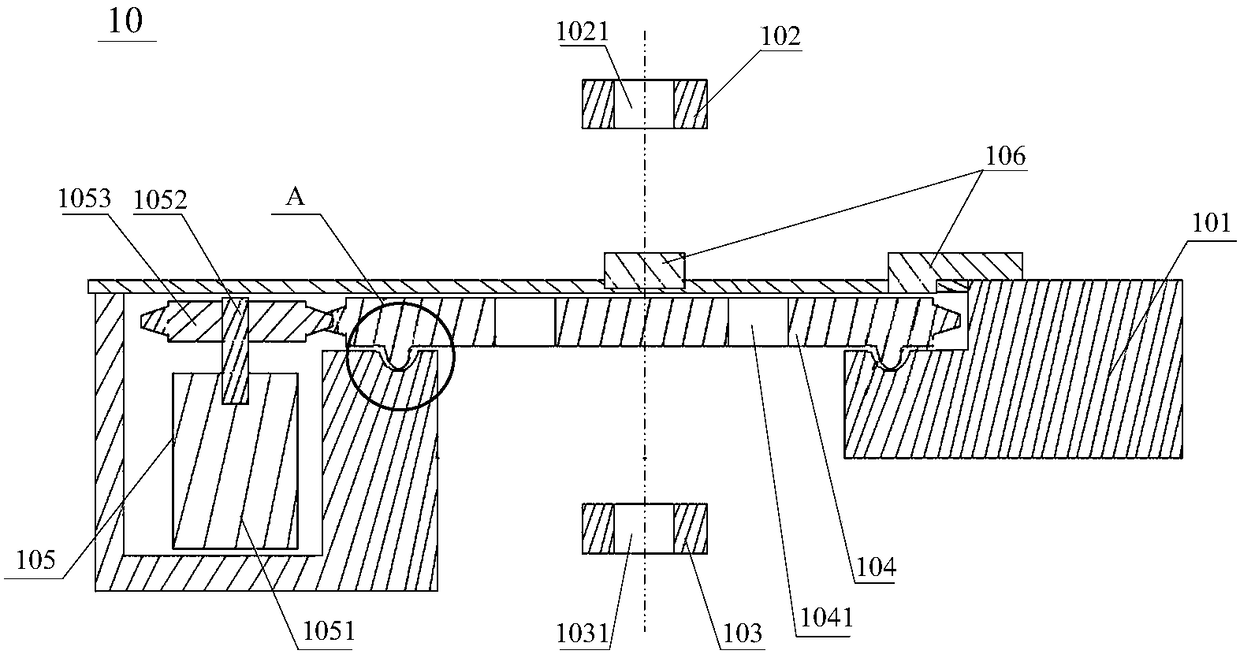

[0067] refer to Figure 8 as shown, Figure 8 It is a schematic cross-sectional structure diagram of an optical fiber twisting device provided by an embodiment of the present invention. The fiber twisting device includes a fiber twisting device 10 including a first limiting member 102 , a second limiting member 103 , a rotating disk 104 and a driving assembly 105 .

[0068] Specifically, the first limiting member 102 and the second limiting member 103 are symmetrically arranged on the upper and lower sides of the edge of the rotating disk 104; the distance between the first limiting member 102, the second limiting member 103 and the rotating disk 104 adjustable. Wherein, the first limiting member 102 and the second limiting member 103 may be respectively fixed on a supporting structure (not shown).

[0069] The first stopper 102 is provided with a first through hole 1021 for the introduction of the optical fiber 13, the second stopper 103 is provided with a second through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com