Internal glass finned-plate tube solar energy steam producing device

An inner glass fin tube and solar energy technology, which is applied to solar thermal devices, solar thermal energy, solar thermal power generation, etc., can solve the problems of insufficiently developed vacuum heat collector tube application products, avoid scaling problems, facilitate water withdrawal, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

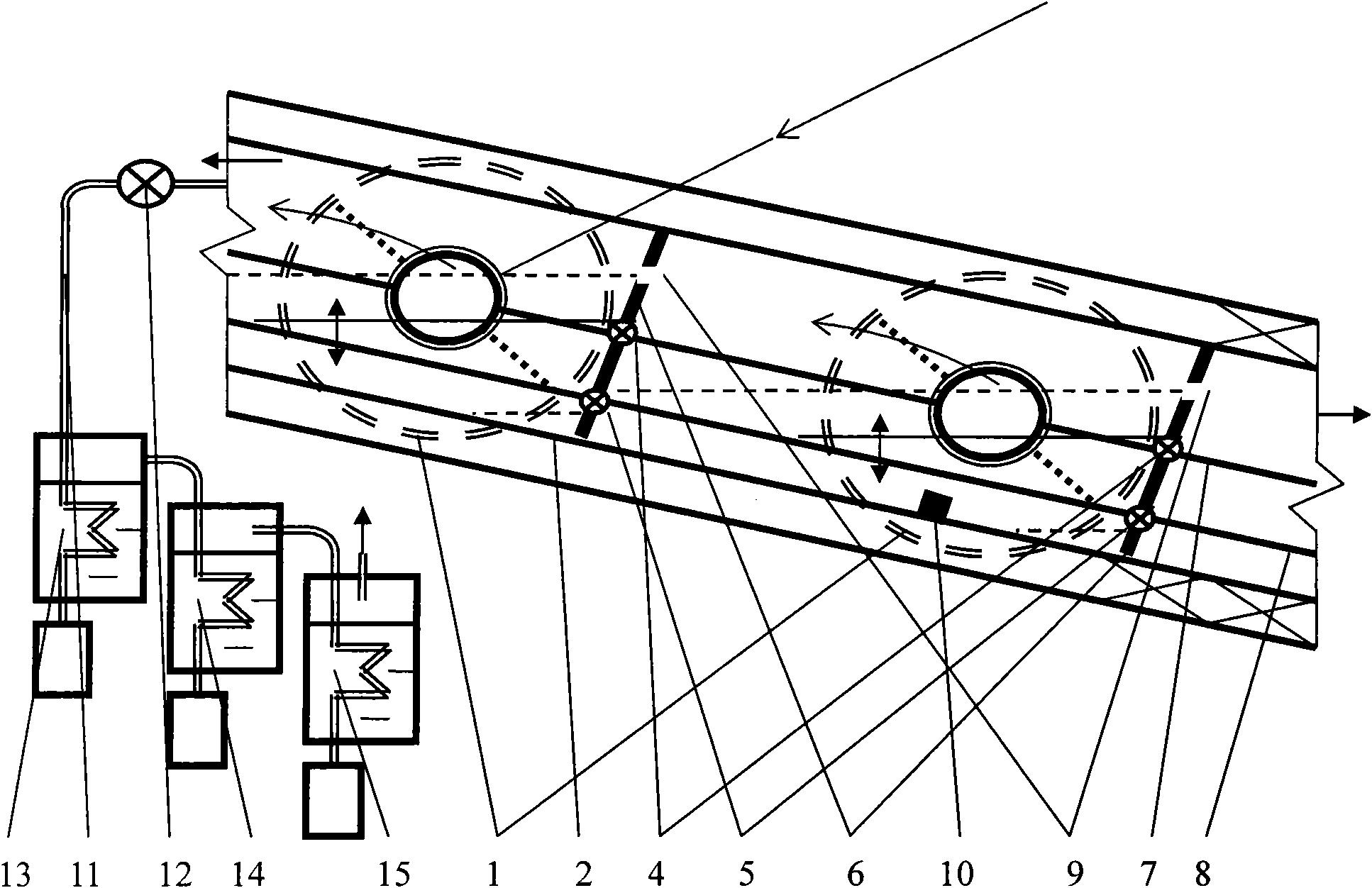

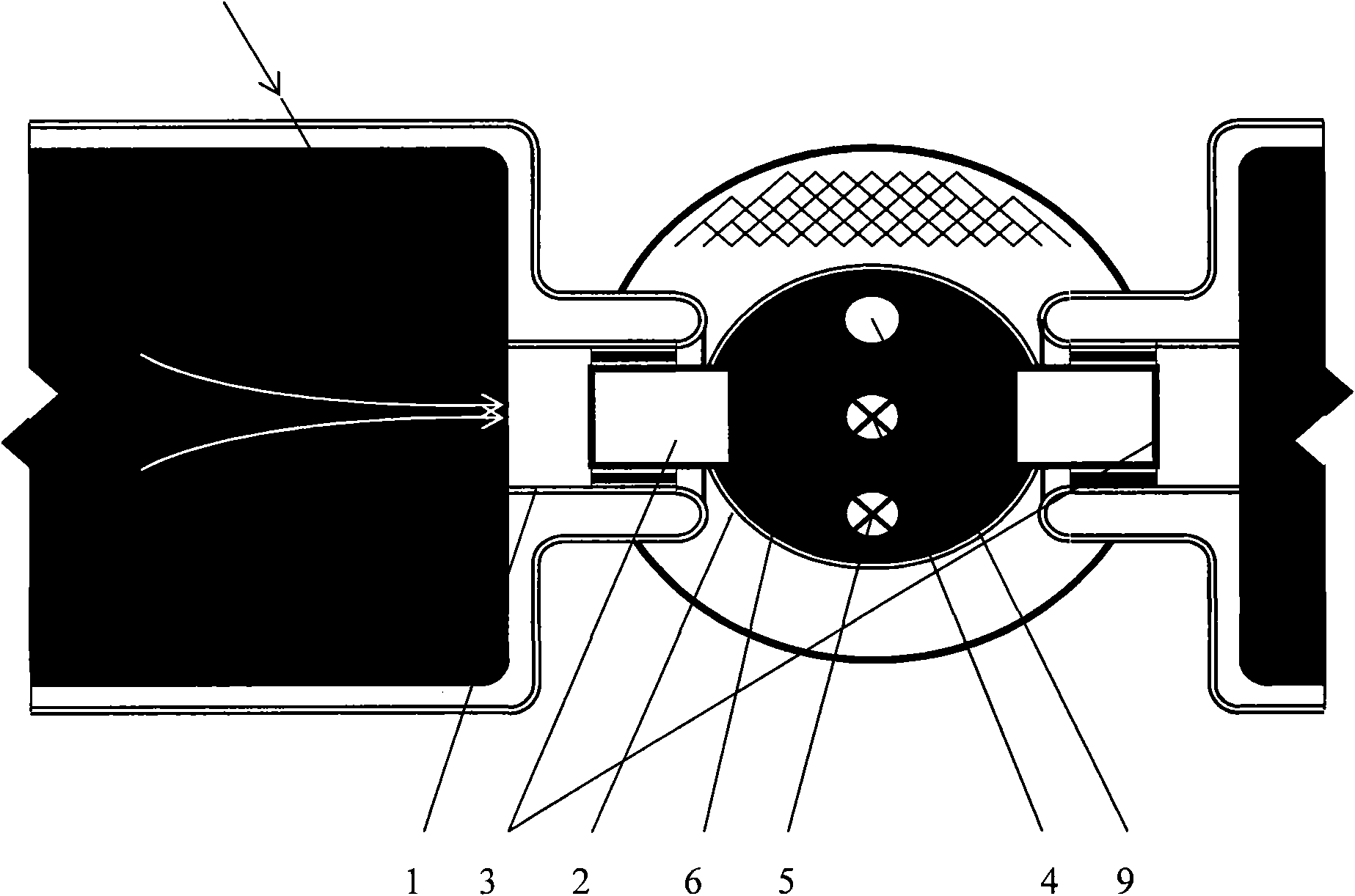

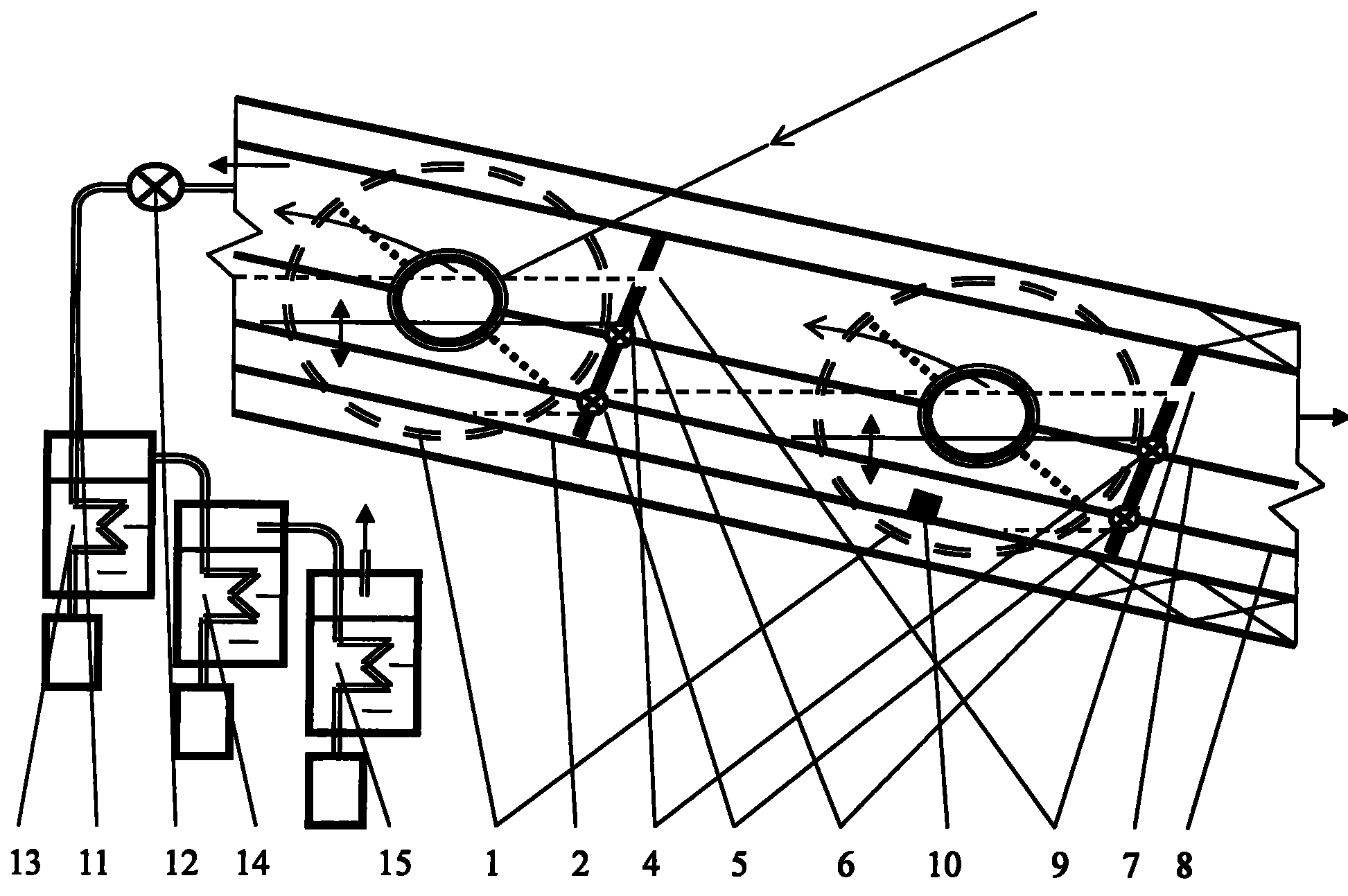

[0016] figure 1 and figure 2 An embodiment of the present invention is collectively given. figure 1 and figure 2 In the above, the heat collecting tube 1 is connected with the barges 3 on both sides of the header box 2 with sealing rings to form a horizontal vacuum heat collecting tube solar steam generating device. The heat collecting tube 1 is arranged horizontally; the collection box 2 has a casing and heat insulating material, and its axis line has a horizontal inclination angle to ensure that the light concentrating reflector can track the change of the sun's altitude angle. For the sake of brevity, the light concentrating reflector is not shown in the figure. Two multi-valve linkage electric group valves, the high group valve 4 and the low group valve 5, are used. Each valve of electric group valve 4,5 is installed on each dam 6 of multi-level cascade dam respectively, and can be opened and closed synchronously by being connected with link rod 7,8 that is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com