Transverse vacuum heat collecting pipe solar steam generating method and device

A vacuum heat collecting tube and heat collecting tube technology, which is applied to solar heat devices, steam generating methods, heating devices, etc., can solve the problem of inconsistent working conditions of heat collecting tubes, deterioration of working conditions of heat collecting tubes, and no scaling and clogging of metal mesh layers. solutions and other problems, to avoid scaling problems and achieve good working condition consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

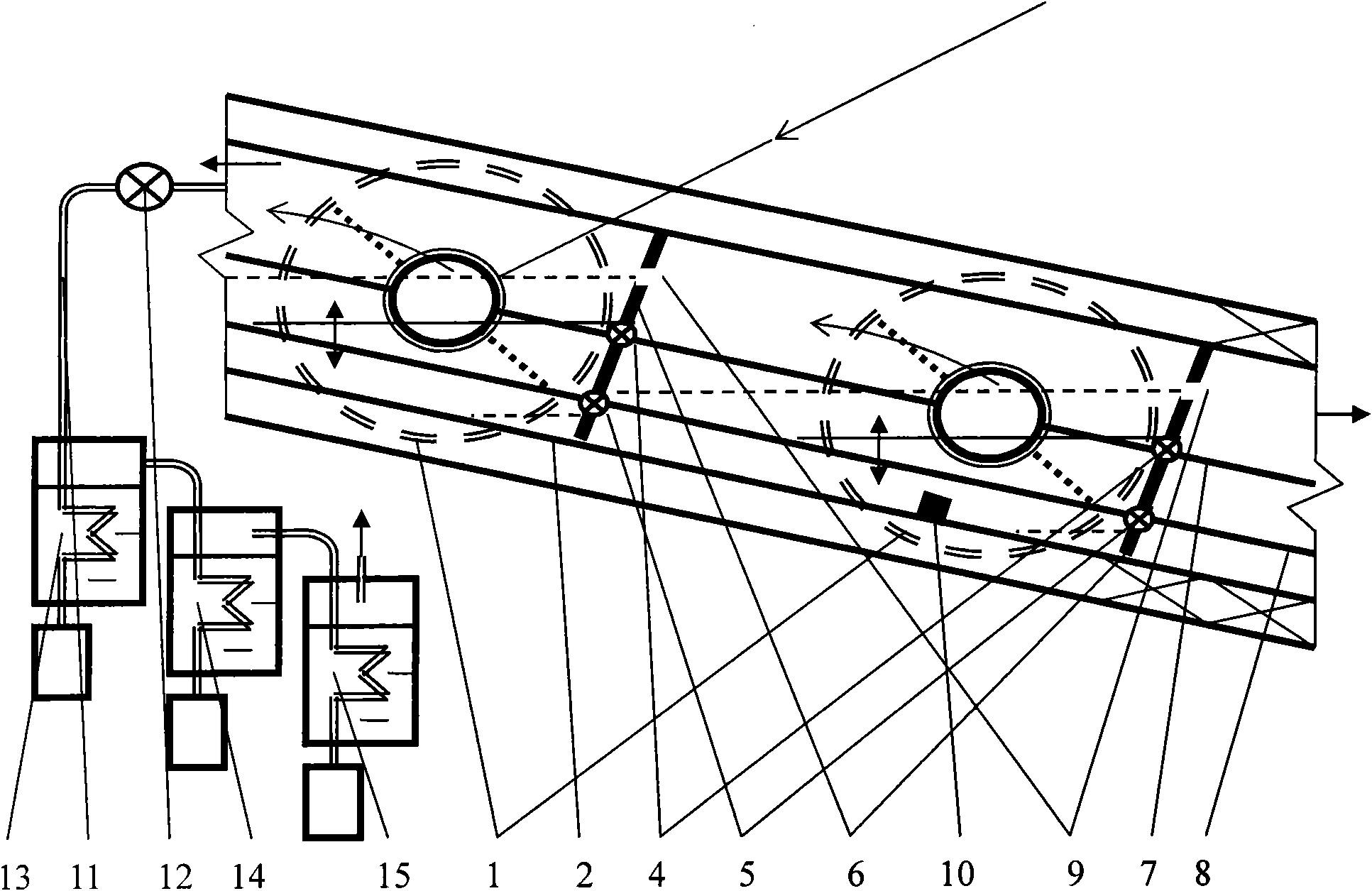

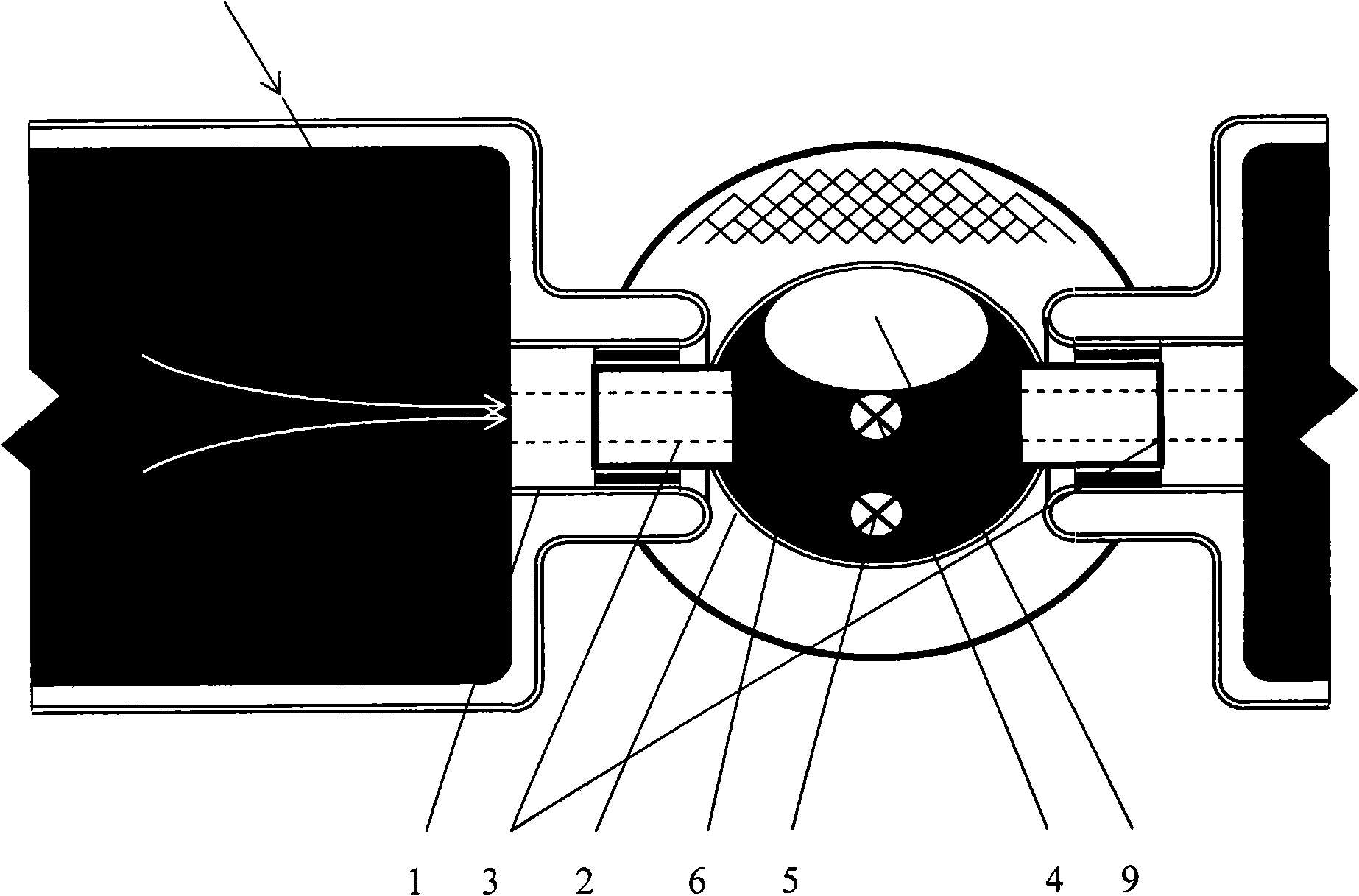

[0019] figure 1 and figure 2 An embodiment of the present invention is collectively given. figure 1 and figure 2 Among them, the vacuum heat collecting tube 1 with the inner glass tube and the metal fin absorber is connected with the barges 3 on both sides of the main tube 2 with sealing rings to form a horizontal vacuum heat collecting tube solar steam generating device. The inner glass tube of the heat collecting tube 1 has a diameter of 25 mm; its cover glass tube is necked down at the port and sealed with the inner glass tube. The vacuum heat collecting tube with the inner glass tube wrapped in metal can use the metal to transfer heat from the heated top of the heat collecting tube to the water storage part below, without using capillary liquid absorption material, and there is no problem of scaling of capillary liquid absorption material. The design freedom of the inner diameter of the heat collecting tube with the inner glass tube and the finned plate is large. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com