Mass and heat recovery system for a fuel cell power plant

A power plant, fuel cell technology, applied in fuel cells, regenerative fuel cells, fuel cell additives, etc., can solve problems such as the complexity of self-sufficient water balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

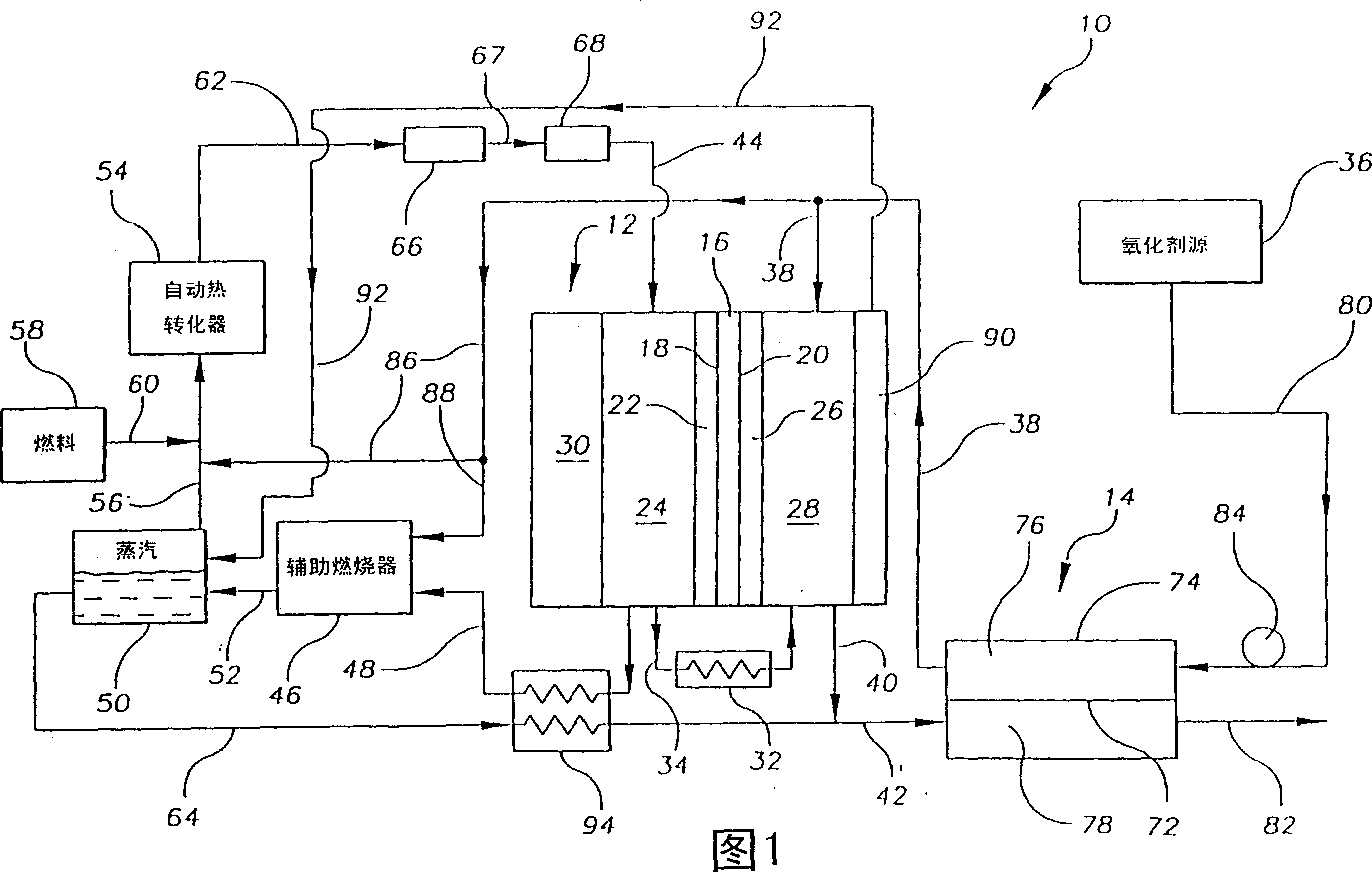

[0039] Referring to the accompanying drawings in detail, the material and heat recovery system of the fuel cell power plant of the present invention is shown in the figure, and is indicated by a reference number 10 . System 10 includes at least a fuel cell 12 and a direct mass and heat transfer device 14 . Fuel cell 12 includes an electrolyte 16, such as a proton exchange membrane ("PEM") or an acid or base electrolyte, having a first major surface 18 and an opposing second major surface 20; an anode electrode 22, supported by a porous anode support layer 24, and in intimate contact with the first major surface 18 of the electrolyte 16; and a cathode electrode 26, supported by a porous cathode support layer 28, and in intimate contact with the second major surface 20 of the electrolyte 16 touch. The anode and cathode porous support layers 24, 28 may be formed from porous or grooved graphite, carbon or metal plates. Fuel cell 12 may be combined with other substantially identi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com