Nozzle position correcting mechanism and application device with same

A technology for nozzles and positioning components, which is applied to the device, spray device, coating and other directions for applying liquid to the surface to achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

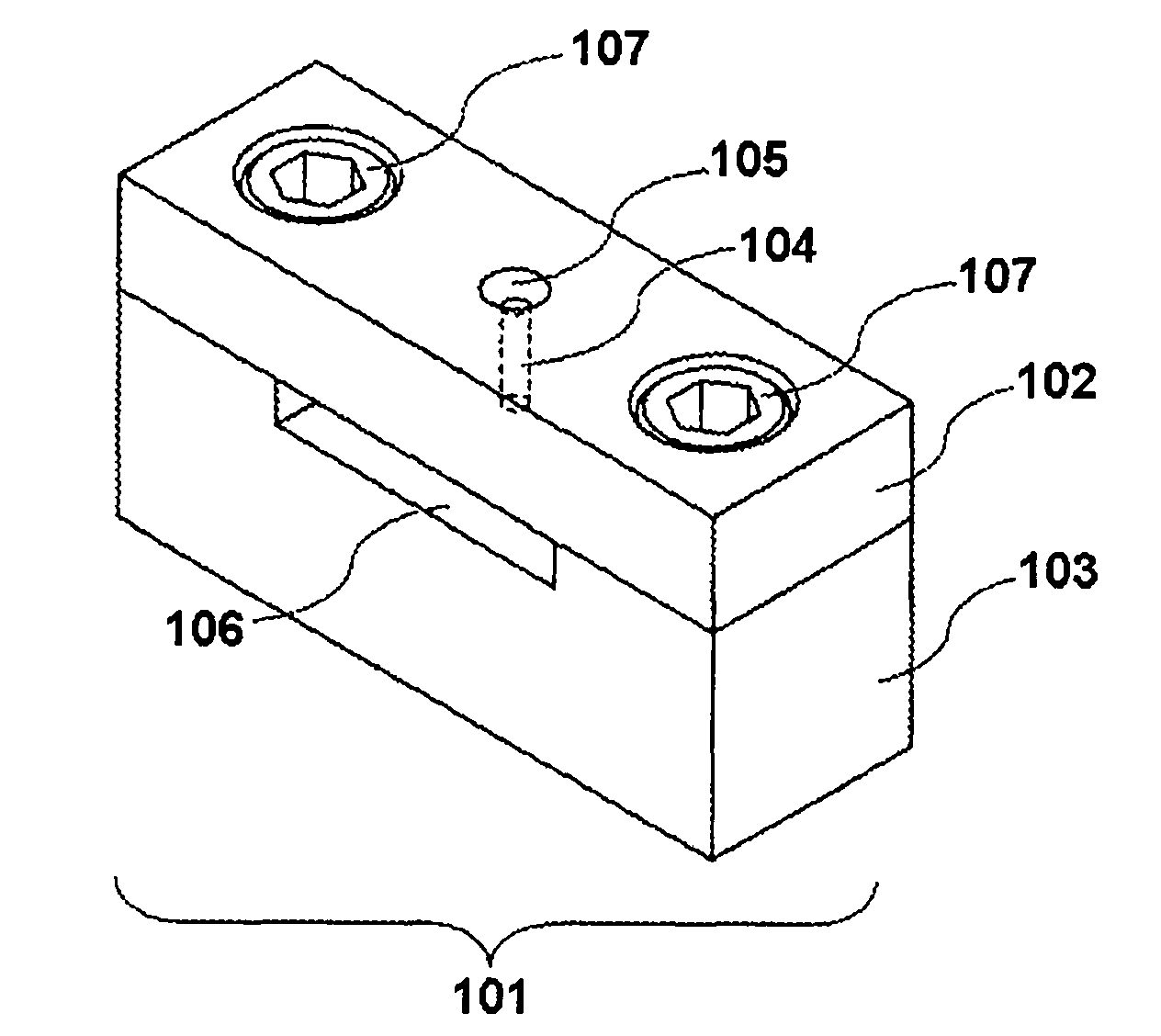

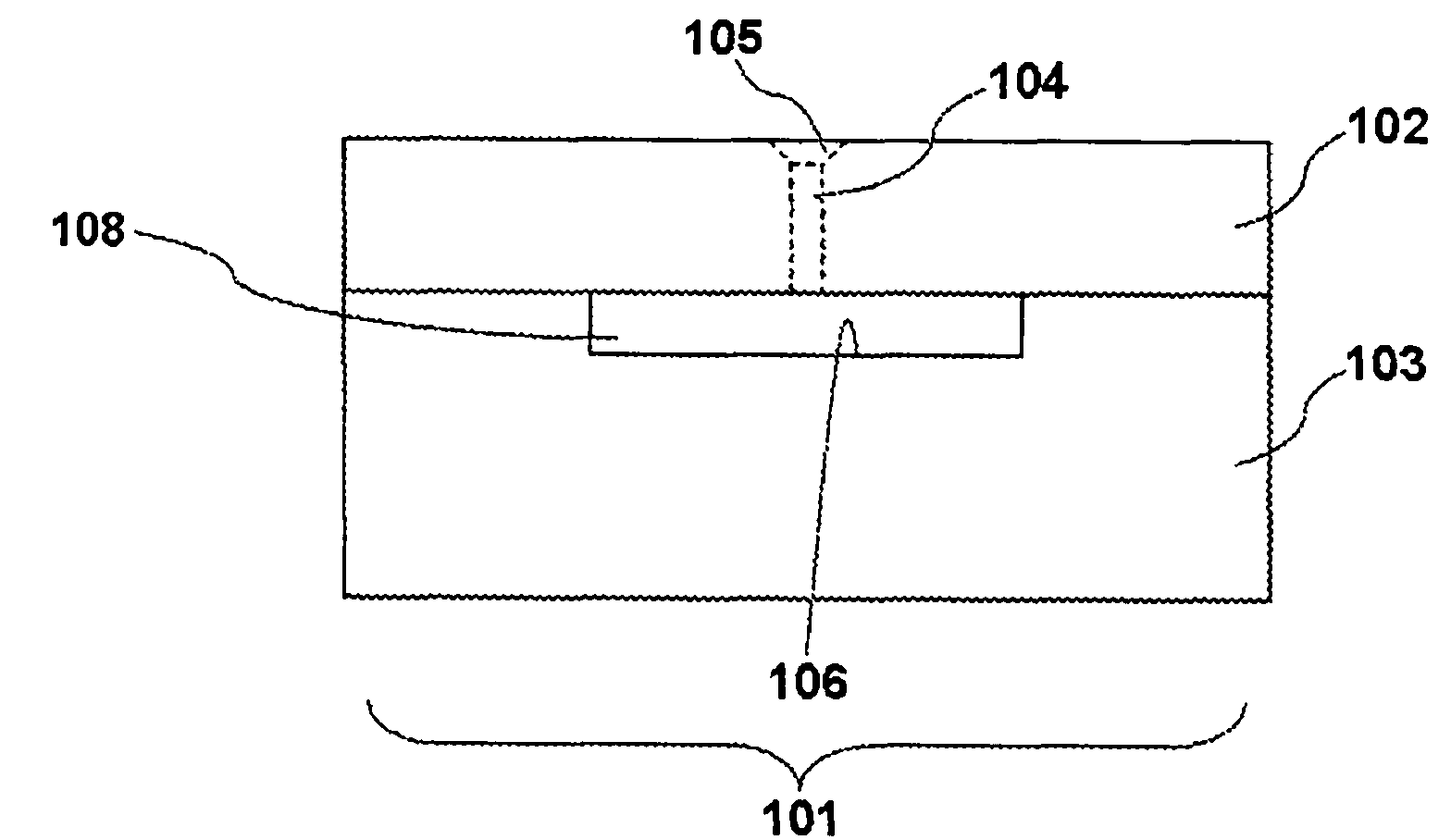

Embodiment 1

[0107] (coating device)

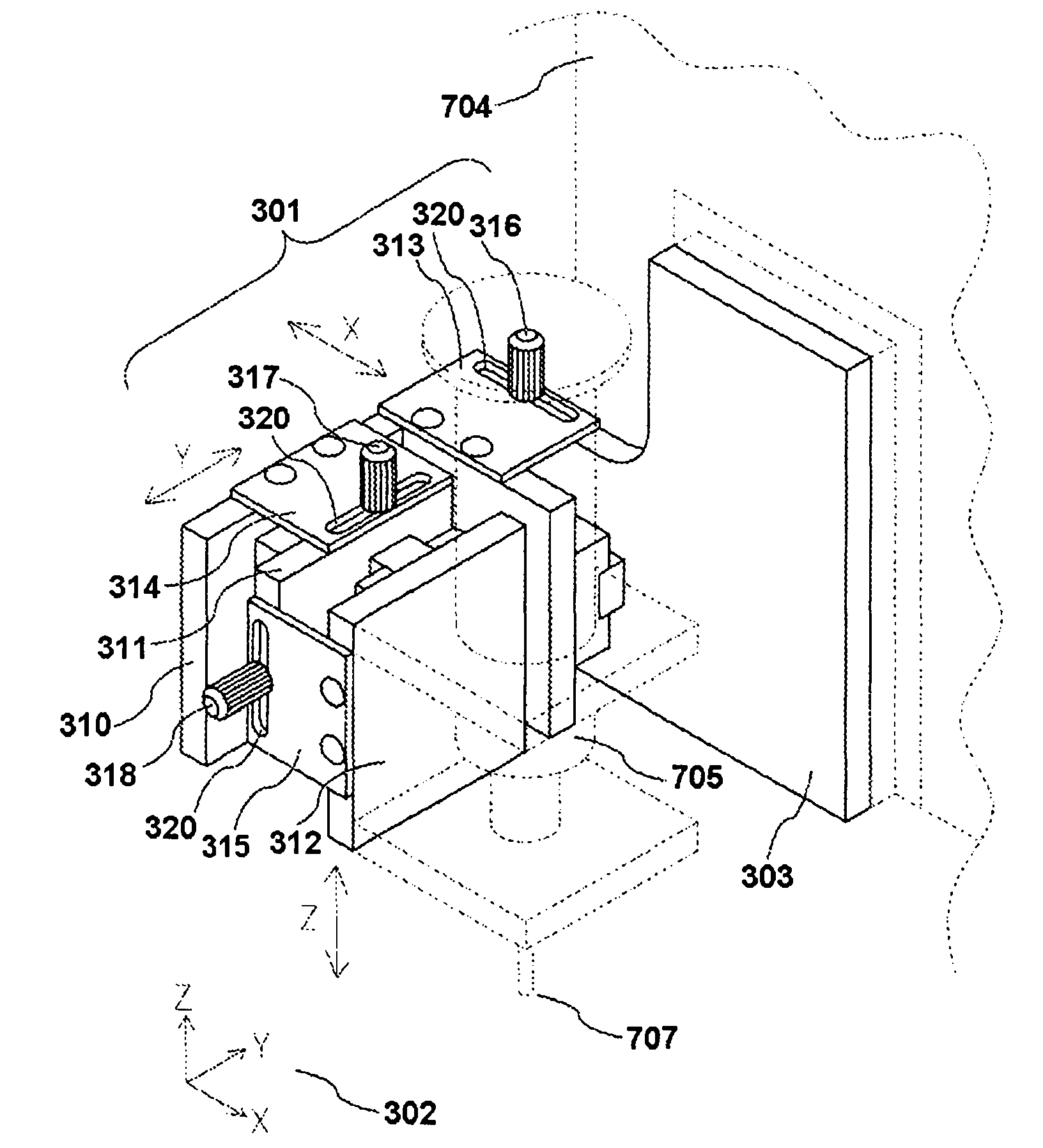

[0108] Such as Figure 7 As shown, the coating device 701 of this embodiment includes an X driving mechanism 702, a Y driving mechanism 703, a Z driving mechanism 704, a discharge device 705, and a control unit 709 for controlling these operations.

[0109] A Z drive mechanism 704 is provided on the X drive mechanism 702 . A workbench 710 on which an object to be coated 708 is placed is provided on the Y drive mechanism 703 . The discharge device 705 includes a storage container 706 capable of storing a liquid material, and a nozzle 707 that discharges the liquid material from the tip thereof. Although the combination of the storage container 706 and the nozzle 707 is shown as the discharge device 705, it is not limited thereto, and any device may be used as long as it has the nozzle 707.

[0110] The adjustment mechanism 301 is arranged between the Z drive mechanism 704 and the ejection device 705 . At this time, the adjustment mechanism 301, the...

Embodiment 2

[0114] (Example of a configuration in which multiple holes are provided in the positioning member)

[0115] In Example 1, although the nozzle fitting hole 104 of the positioning member 101 is one, a plurality of holes ( 805 to 809 ) with different inner diameters may be provided in order to accommodate a plurality of types of nozzle diameters assumed to be used. Figure 8 An example of this configuration is shown.

[0116] Figure 8 The illustrated positioning member 801 is composed of two members, a fitting member 802 and an abutting member 803, as in the first embodiment. In the fitting member 802, a hole 805 for fitting the most frequently used nozzle is provided at the center. Also, holes (806, 807) having a larger diameter than the central hole 805 are provided on the right side thereof, and holes (808, 809) having a smaller diameter than the central hole 805 are provided on the left side. The same tapered portion 810 as above is provided in each hole (805-809) in acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com