Liquefied gas storage tank and marine structure comprising same

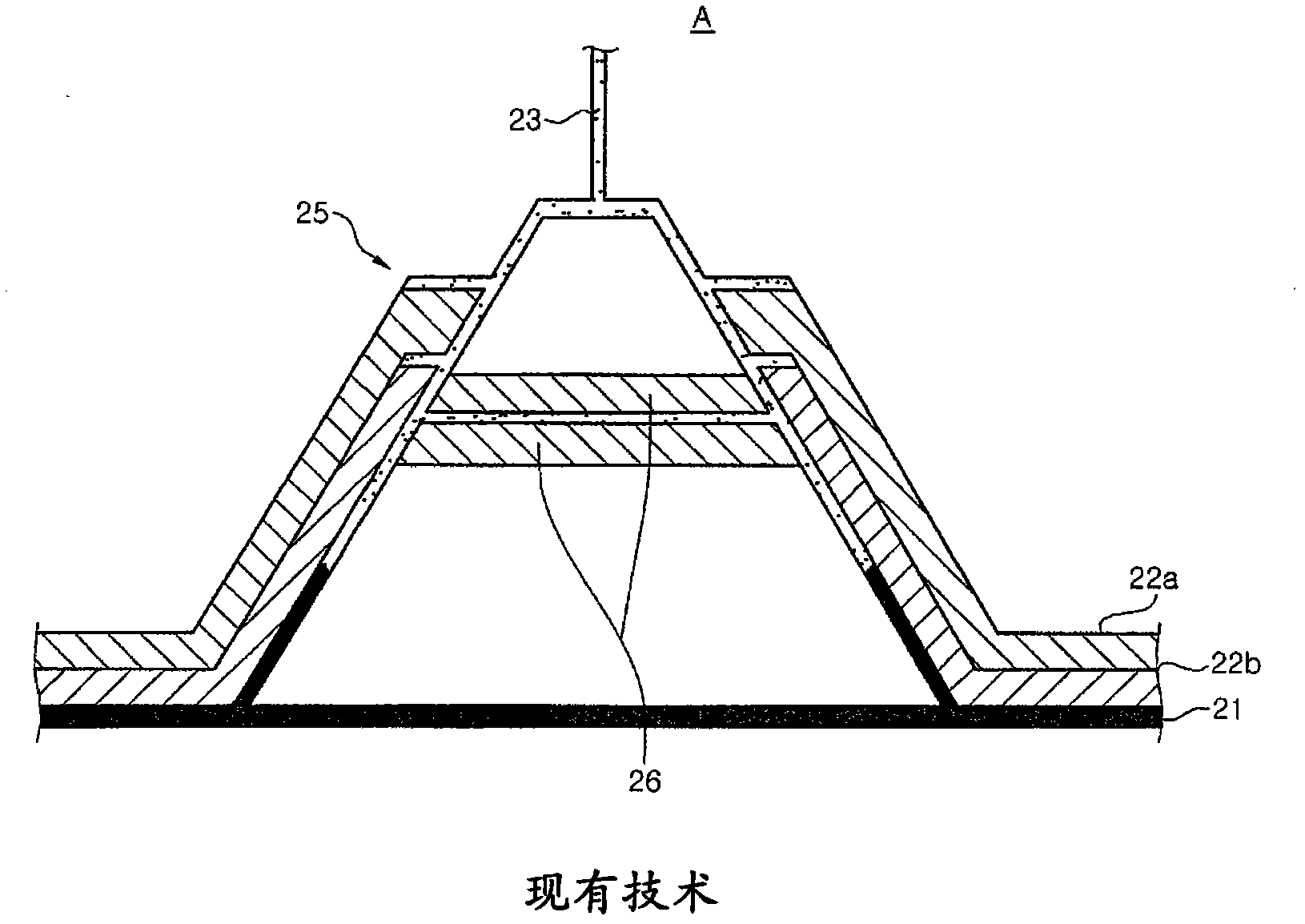

A liquefied gas storage tank, liquefied gas technology, applied in the direction of gas processing/storage, transportation and packaging, fixed-capacity gas storage tanks, etc., can solve the problem of the reduction of the thermal insulation performance of the storage tank 20, the damage of the primary and secondary barrier layers, Problems such as an increase in the amount of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0066] Herein, the term "maritime structure" refers to any structure or vessel that contains storage tanks for storing liquid cargo (such as LNG) in a cryogenic state and is used in a floating state at sea. For example, the marine structures include not only floating structures such as LNG FPSO or LNG FSRU, but also vessels such as LNG carriers or LNG RVs (Regasification Vessels).

[0067] Figure 4 is a schematic plan view of a marine structure including a liquefied gas storage tank according to a first embodiment of the present invention, and Figure 5 is a transverse cross-sectional view of a marine structure including a liquefied gas storage tank according to a first embodiment of the present invention.

[0068] see Figure 4 with Figure 5 , the liquefied gas storage tank 110 according to the first embodiment includes a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com