Liquid food heating and stirring foaming machine

A technology of heating, stirring and liquid food, which is applied in household utensils, applications, kitchen utensils, etc., and can solve problems such as inability to be cleaned and disinfected by dishwasher, complicated and uneven structure, and inconvenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

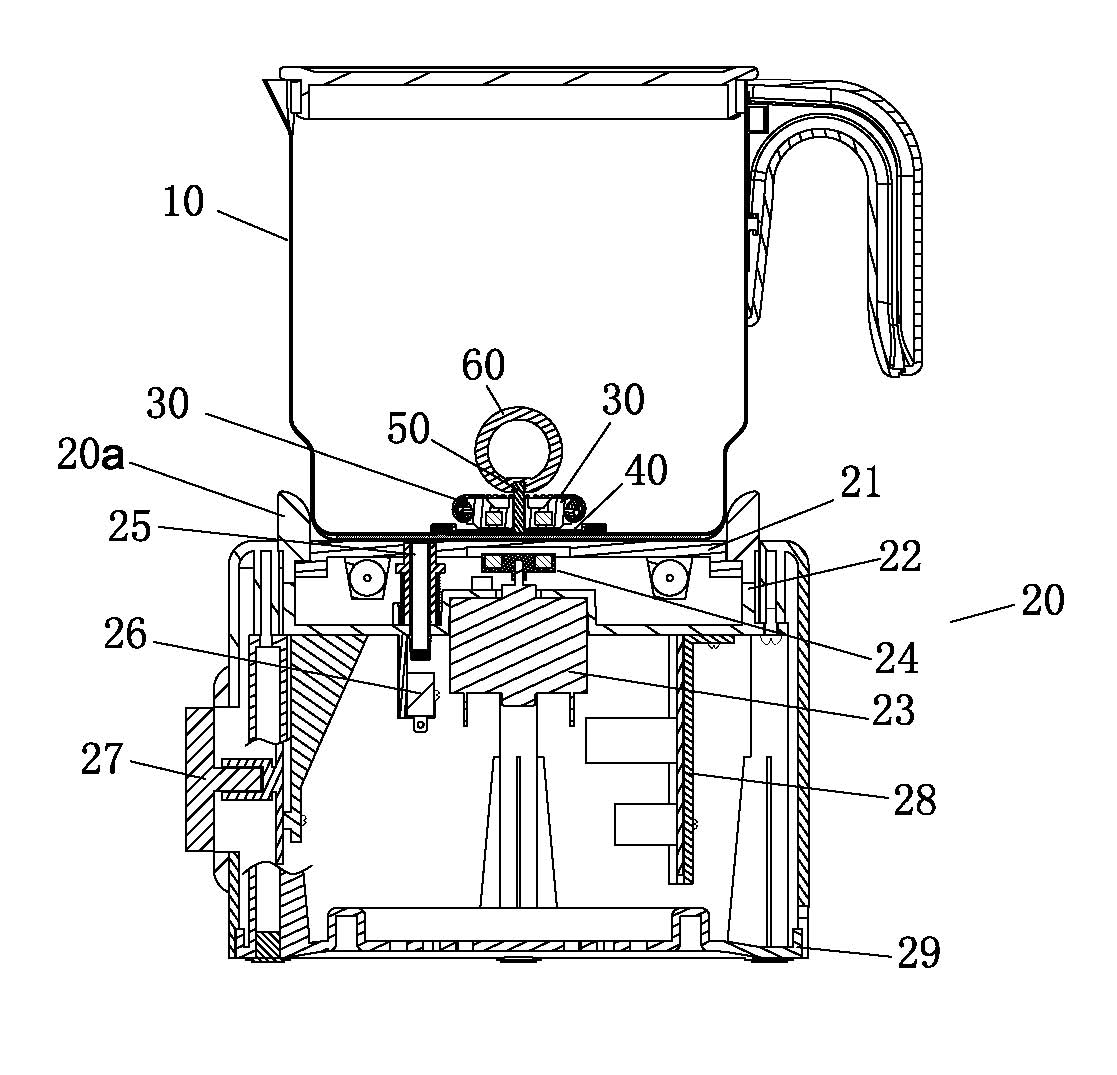

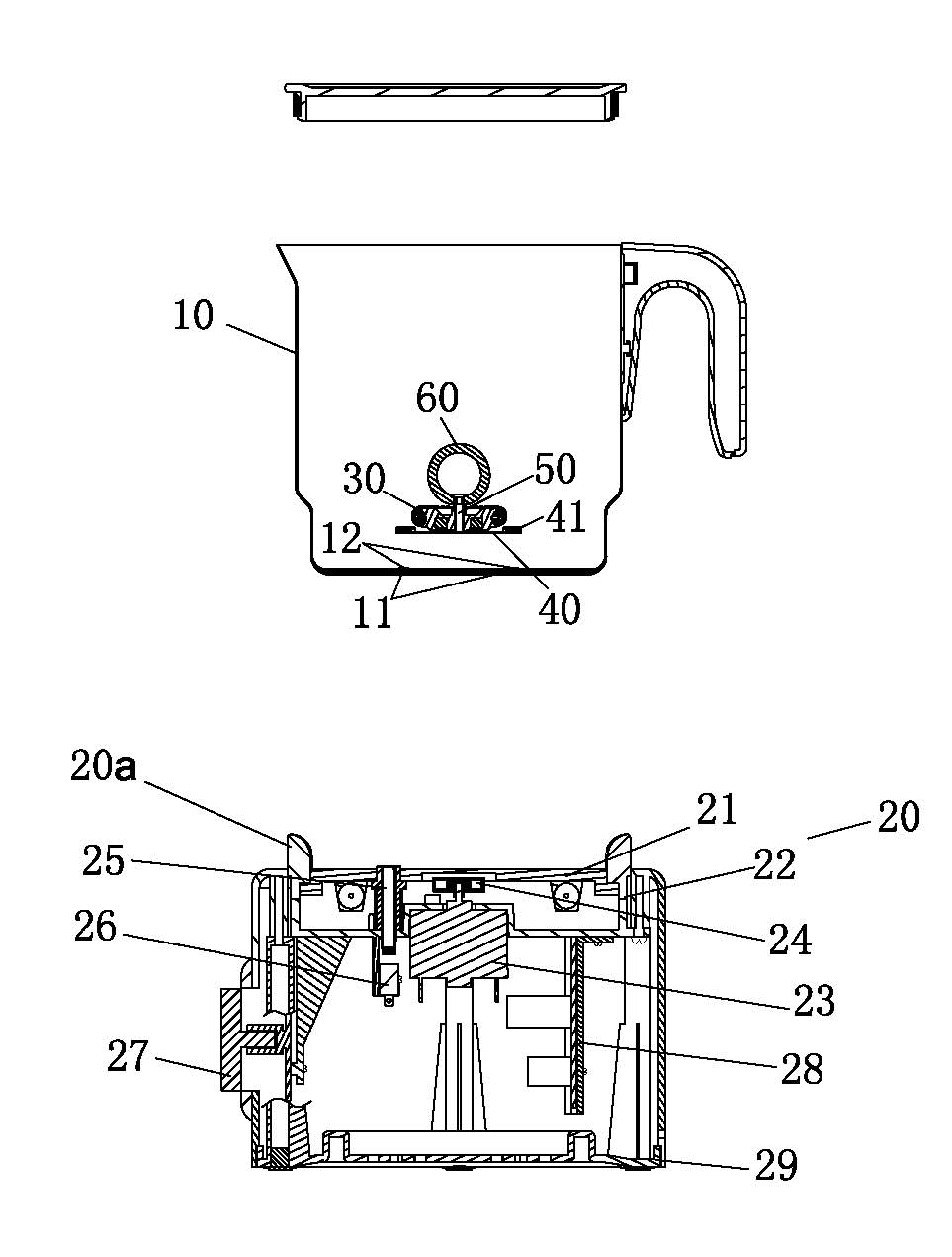

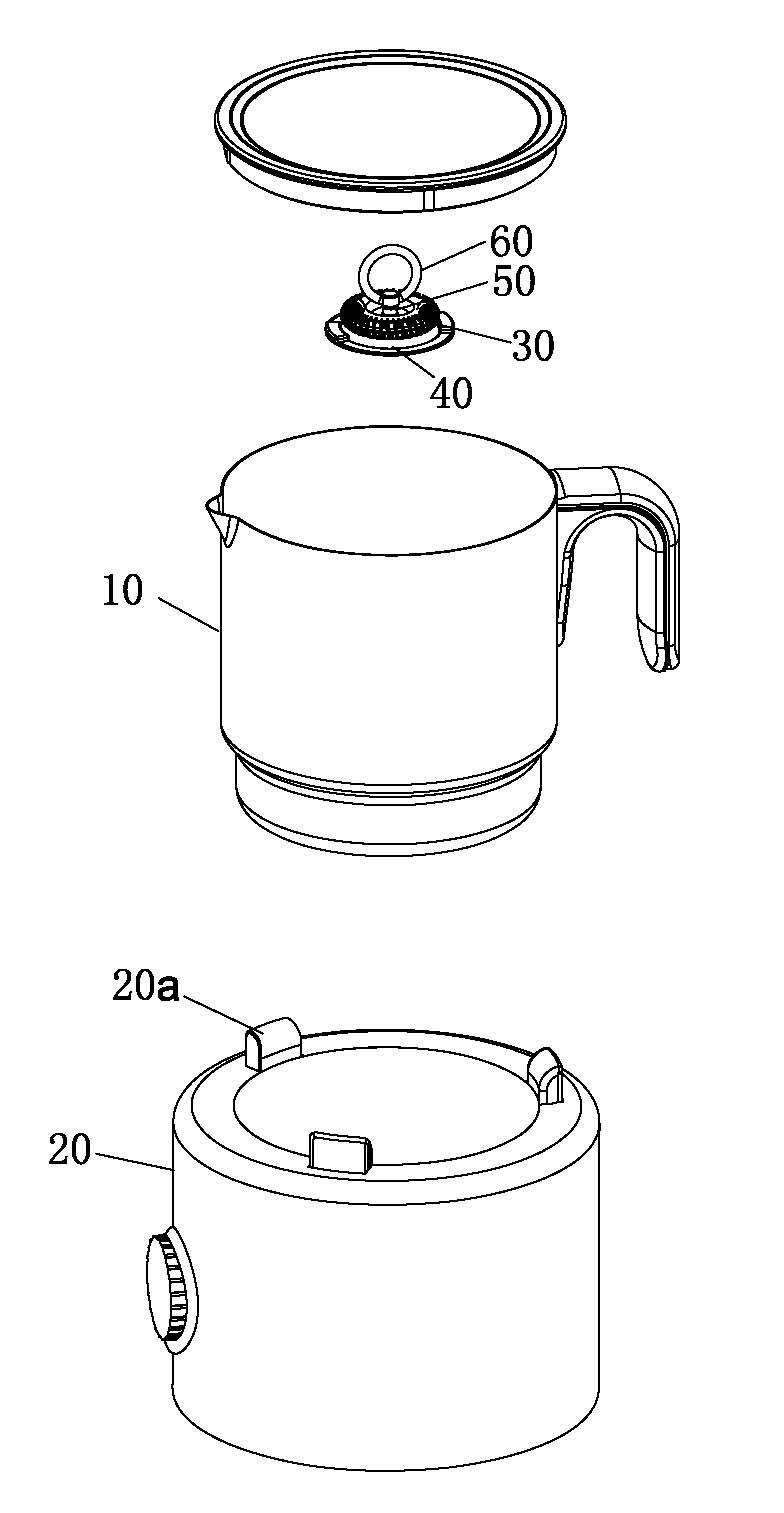

[0029] Such as Figure 1-14 As shown, a liquid food heating and stirring foaming machine includes a cup 10 and a base 20, the cup 10 is arranged on a heating plate 21 in the base 20, a rotatable stirrer 30 is arranged in the cup 10, and the base 20 Inside is provided with heating disc 21, heat shield 22, motor 23, magnet disc 24 installed on the motor shaft, temperature controller 25, micro switch 26, switch plate 27, control circuit board 28 and base 29, when working , the magnetic disc 24 on the motor shaft rotates with the motor 23 to drive the stirrer 30 with a magnet at the inner bottom of the cup 10 to rotate, and the control circuit board 28 and the motor 23, the heating plate 21, the temperature controller 25, the micro The movable switch 26 and the switch plate 27 are electrically connected, and the inner bottom of the cup 10 is also placed with a support 40 for supporting and positioning the agitator 30 and an agitator central axis 50 suspended on the bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com