Welding supporting table for joints

A support table, rectangular technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low operation efficiency, complex structure, high cost, achieve firm and stable support, improve support strength, realize Efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

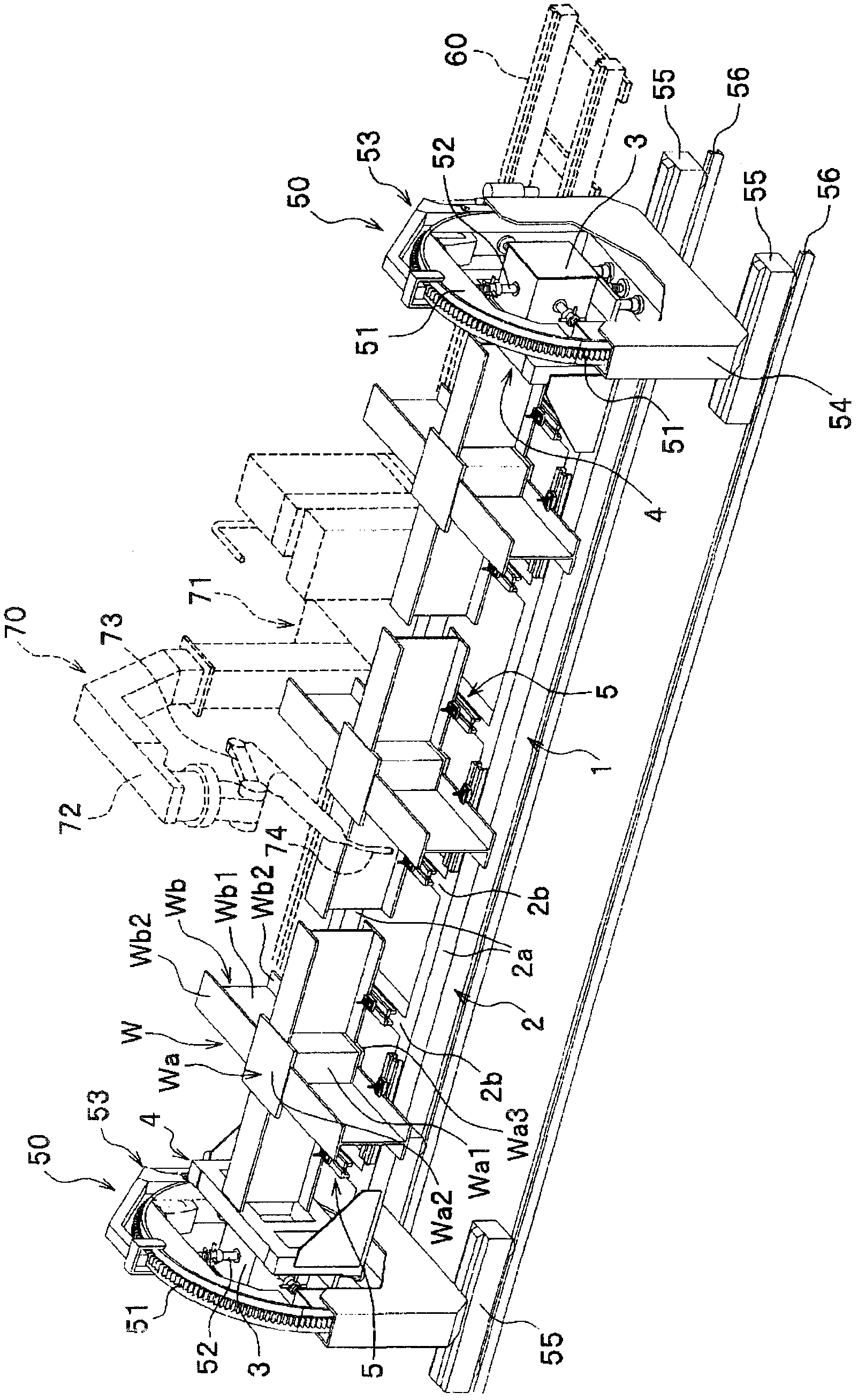

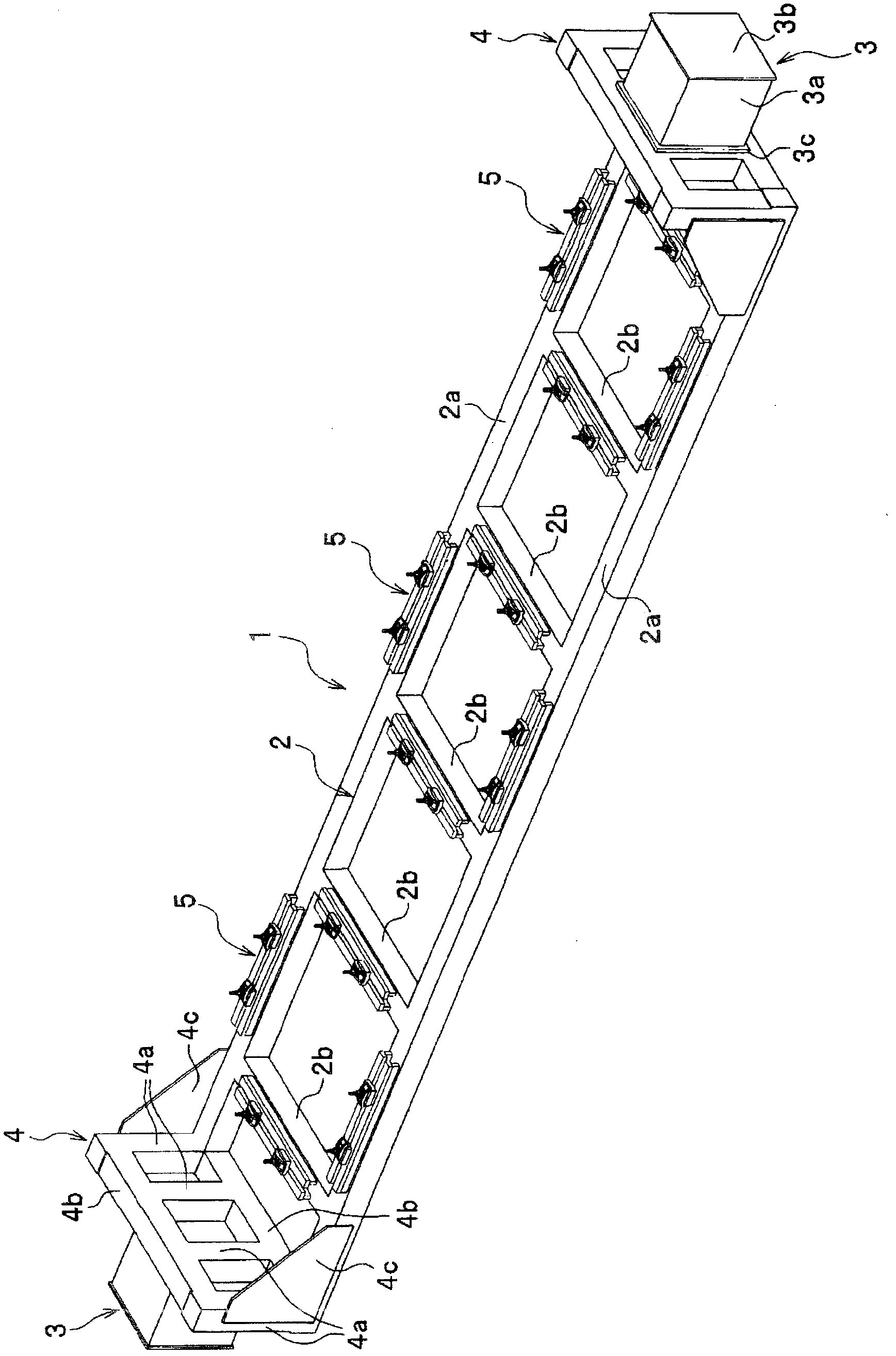

[0037] Such as figure 1 As shown, the joint welding support table 1 supports a plurality of (here, three) joints W, and is held between existing rotary positioners 50 and 50 for use. In addition, a conventional welding device 70 is installed along a direction straddling between the rotary indexers 50 and 50 .

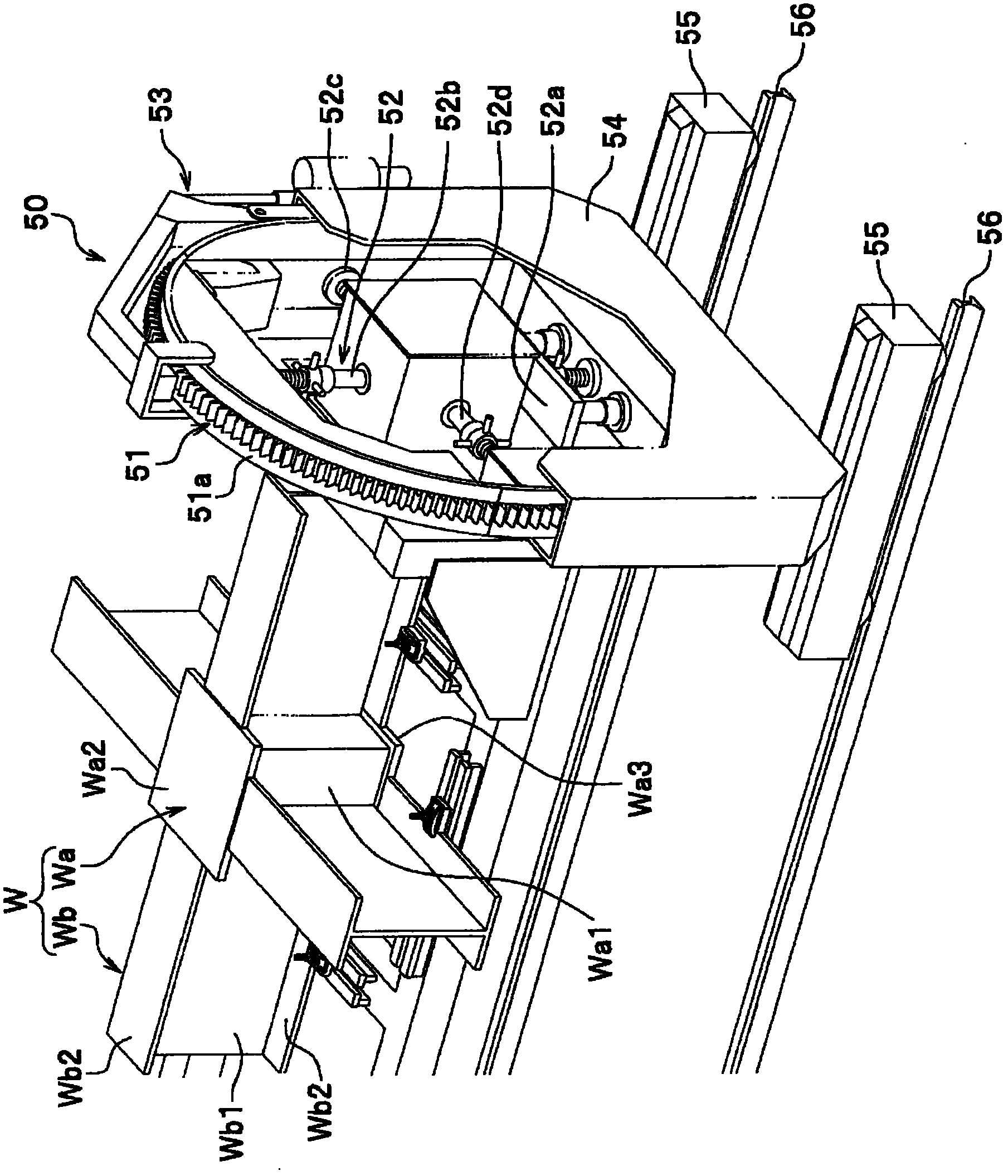

[0038] The rotary positioner 50, 50 is a device with a conventional structure, holds the welding support table 1 for a workpiece or a joint as a welding object, and moves the held workpiece or welding support table 1 for a joint from The basic position is rotated by a predetermined angle or moved on the moving rail 56 for a positioner, and the welding support table 1 for workpieces or joints is moved in a sliding manner. Also, the composition of the rotary transposer 50, 50 is as follows: figure 1 As shown, the fixing jig 52 held from four sides towa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com