Seamless belt forming die and manufacturing method thereof

A molding die, seamless technology, applied in the direction of belts, household appliances, other household appliances, etc., can solve the problems of thickness uniformity, poor surface smoothness, poor uniformity and difficulty in dispersion of additives, conductive fillers, etc., and achieve excellent uniformity. , Excellent surface smoothness, excellent uniformity of surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

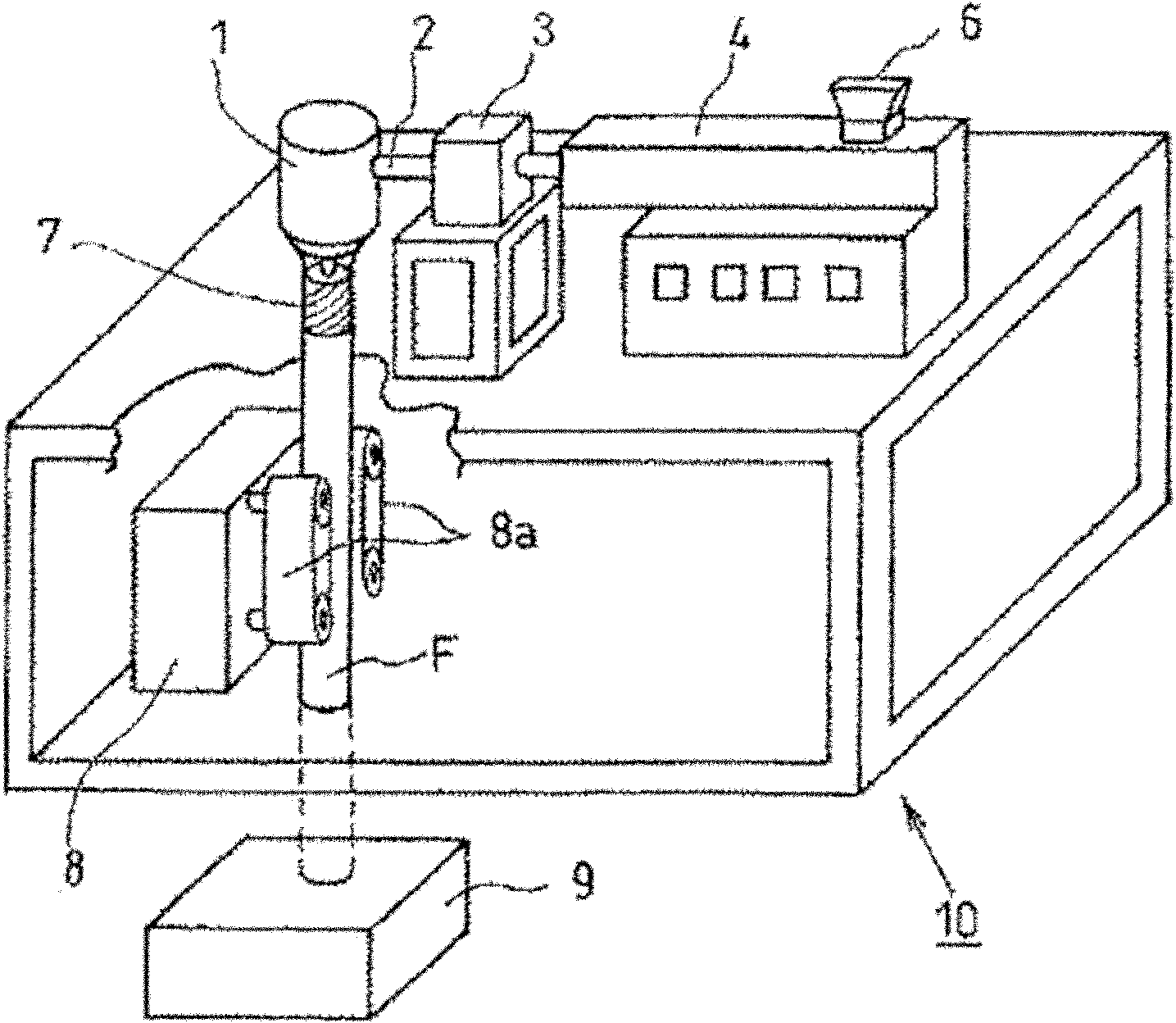

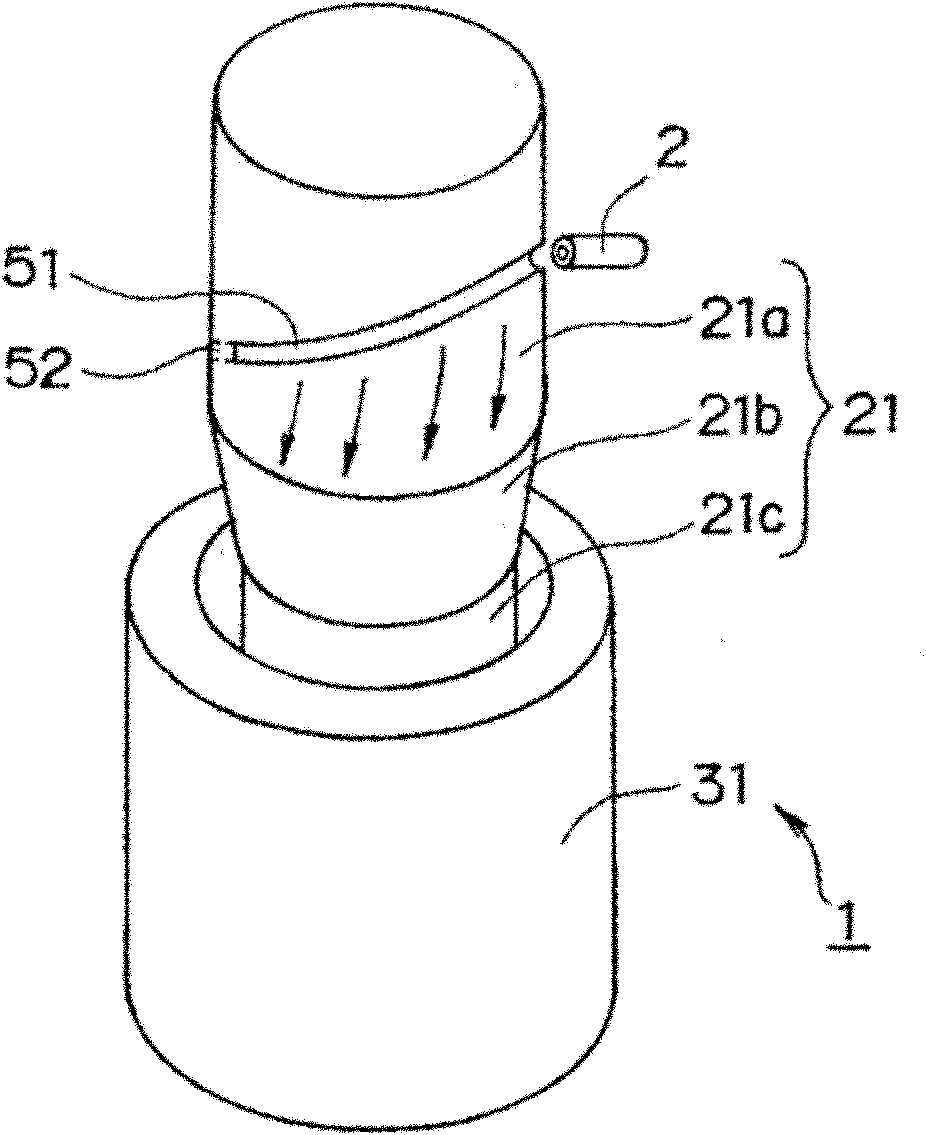

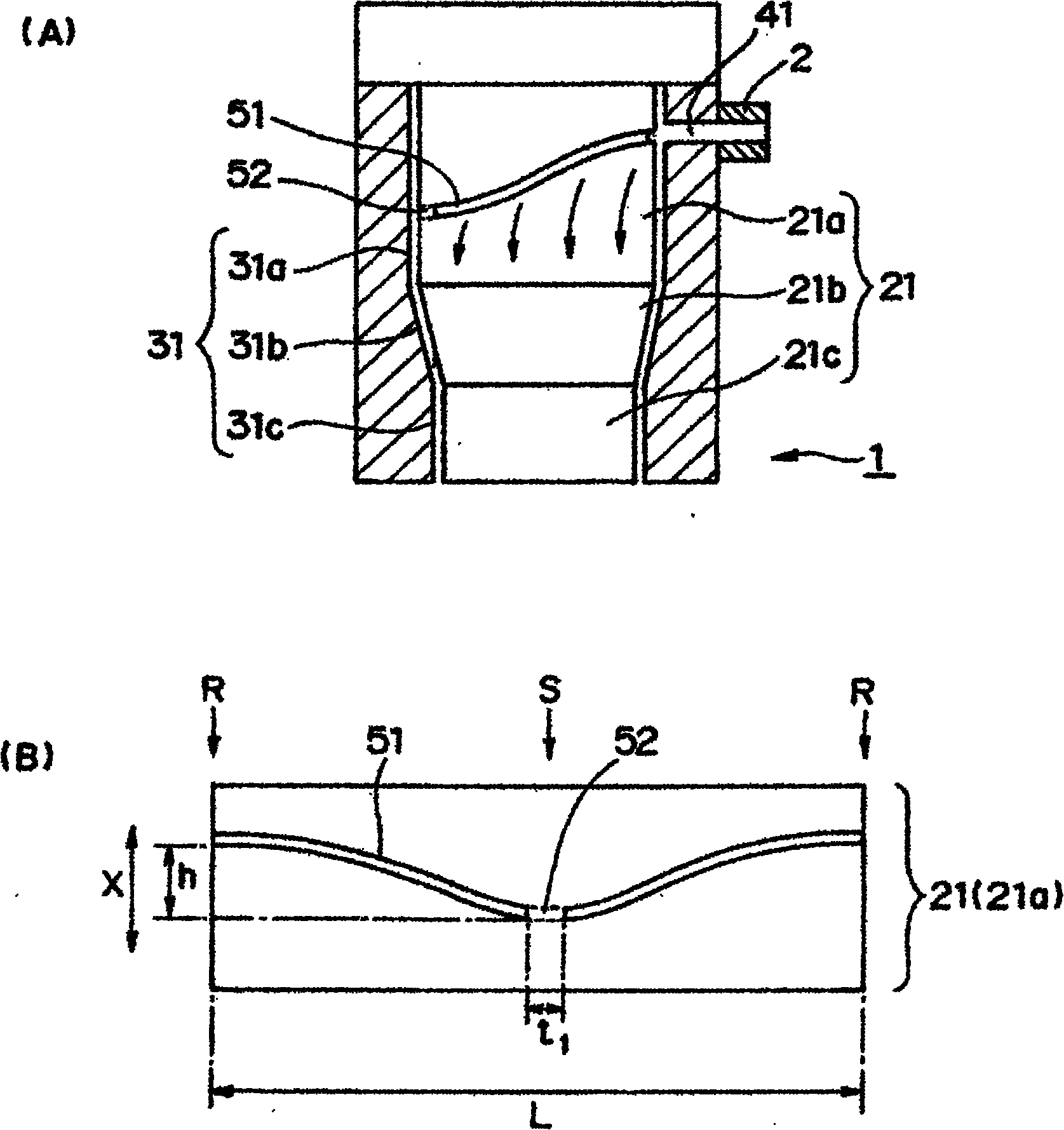

[0093] use has Figure 4 The molding die shown is 1 of the figure 1 The shown seamless belt manufacturing apparatus 10 is used to manufacture an intermediate transfer belt. In more detail, 84.7 parts by weight of polyphenylene sulfide (E2180; manufactured by Toray Corporation), 6.0 parts by weight of nylon resin (polyamide resin CM1021T; manufactured by Toray Corporation), and 9.3 parts by weight of acid carbon black (Printex U; manufactured by Ebonic Degusa Corporation) The mixture is put into the raw material input port 6 of the extruder 4, and the mixture is melted and mixed by the extruder 4, and then extruded, and the extruded molten resin is further injected from the resin injection pipe 2 through the gear pump to the prescribed molding machine. The resin injection port 41 of the mold 1 . Various conditions of the molding die 1 are shown in Table 1. The stopper 52 is provided at a predetermined position in the hanger-shaped resin flow path by predetermined groove for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com