A Method for Improving the Standing Wave Ratio of Composite Material Antenna

A composite material and antenna technology, applied in the field of antennas, can solve problems such as inconsistent surface resistance, poor standing wave ratio, uneven coating, etc., and achieve uniform surface resistance, improved uniformity, and enhanced matching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

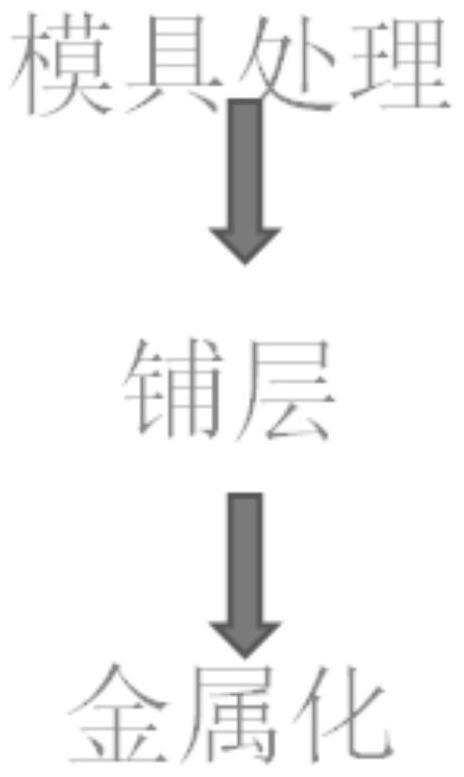

Image

Examples

Embodiment 1

[0031] First of all, apply the release agent to the tooling, and the surface temperature of the tooling should not be lower than 15°C when painting. If it is the first time to apply the release agent, apply three continuous and complete thin layers of release agent on the surface of the tooling, each layer is perpendicular to the coating direction of the previous layer, each layer needs to be dried for at least 15 minutes, and the final coating After the coating is completed, it should be dried for at least 30 minutes, and it should be dried at 120±5°C for at least 30 minutes before starting to lay the layer. If the release agent is applied again, apply one or more layers of release agent. If multiple layers are applied, each layer needs to be dried for at least 15 minutes. Let dry for at least 30 minutes. If the tooling has been sanded, apply the release agent as the first application.

[0032] Next, thaw the prepreg and film. The bag can only be removed after the material...

Embodiment 2

[0040] First of all, apply the release agent to the tooling, and the surface temperature of the tooling should not be lower than 15°C when painting. If it is the first time to apply the release agent, apply three continuous and complete thin layers of release agent on the surface of the tooling, each layer is perpendicular to the coating direction of the previous layer, each layer needs to be dried for at least 15 minutes, and the final coating After the coating is completed, it should be dried for at least 30 minutes, and it should be dried at 120±5°C for at least 30 minutes before starting to lay the layer. If the release agent is applied again, apply one or more layers of release agent. If multiple layers are applied, each layer needs to be dried for at least 15 minutes. Let dry for at least 30 minutes. If the tooling has been sanded, apply the release agent as the first application.

[0041] Next, thaw the prepreg and film. The bag can only be removed after the material...

Embodiment 3

[0049] First of all, apply the release agent to the tooling, and the surface temperature of the tooling should not be lower than 15°C when painting. If it is the first time to apply the release agent, apply three continuous and complete thin layers of release agent on the surface of the tooling, each layer is perpendicular to the coating direction of the previous layer, each layer needs to be dried for at least 15 minutes, and the final coating After the coating is completed, it should be dried for at least 30 minutes, and it should be dried at 120±5°C for at least 30 minutes before starting to lay the layer. If the release agent is applied again, apply one or more layers of release agent. If multiple layers are applied, each layer needs to be dried for at least 15 minutes. Let dry for at least 30 minutes. If the tooling has been sanded, apply the release agent as the first application.

[0050] Next, thaw the prepreg and film. The bag can only be removed after the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com