Multi-functional constant flow control valve

A control valve, constant flow technology, applied in the direction of functional valve type, safety valve, balance valve, etc., can solve the problems of difficult disassembly and maintenance, complex structure, etc., and achieve the effect of reducing maintenance time and failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

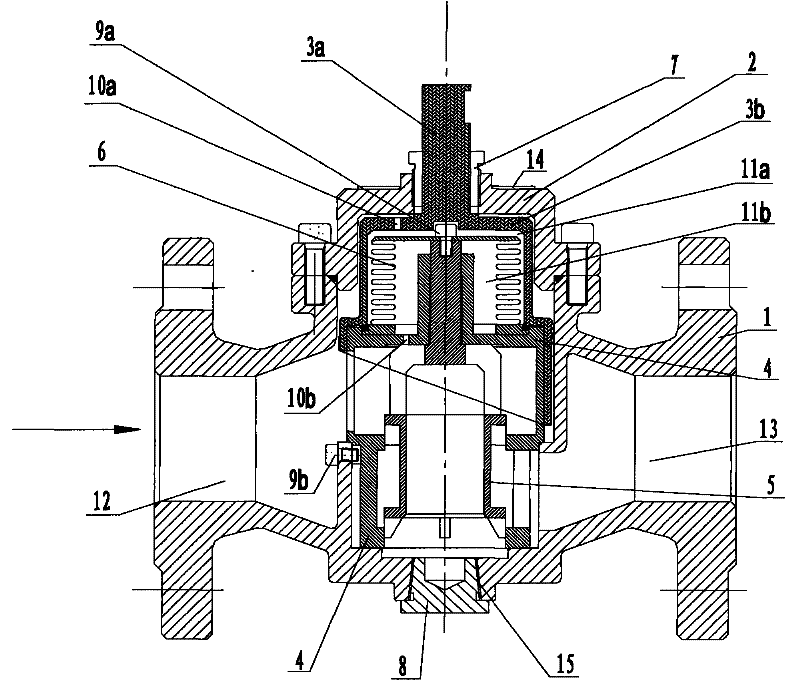

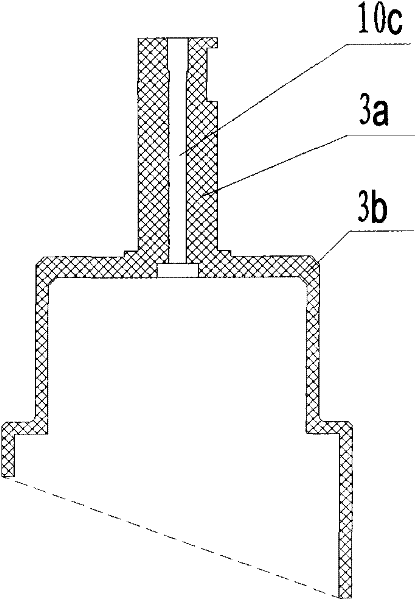

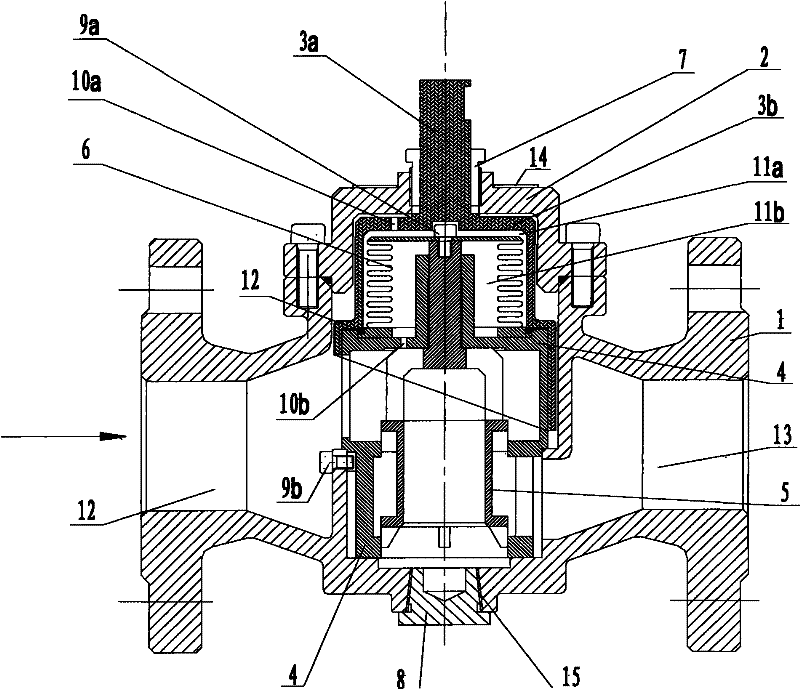

[0017] A multifunctional constant flow regulating valve for fluid regulation and automatic control, including a valve body 1, a valve cover 2 is installed on the valve body 1, a valve shaft 3a, a regulating valve disc 3b, a double-seat valve disc 5, and a valve body 1 are installed in the valve body 1. Cover 4, differential pressure sensor 6. The bonnet 2 presses the pressure flange 7 to adjust the valve disc 3b to achieve positioning. The bonnet 2 is connected to the valve body through the flange, and the bonnet is tightly fixed on the valve body through the ring-shaped sealing boss on the inner side of the lower part of the flange and the sealing ring. On the valve body, and ensure a good sealing effect. The valve shaft 3a can be rotated by different actuators to change the opening degree of the regulating disc to adjust the flow rate. There is a dial 14 on the valve cover 2 to display the flow value.

[0018] In this embodiment, the pressure difference sensor 6 is sealed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com