Vacuum equipment capacity type gravity flow continuous sewage draining system and sewage draining method thereof

A technology of vacuum equipment and sewage system, which is applied in the direction of waterway system, sewage discharge, sewer pipeline system, etc., and can solve the problems such as the difficulty of vacuum equipment sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

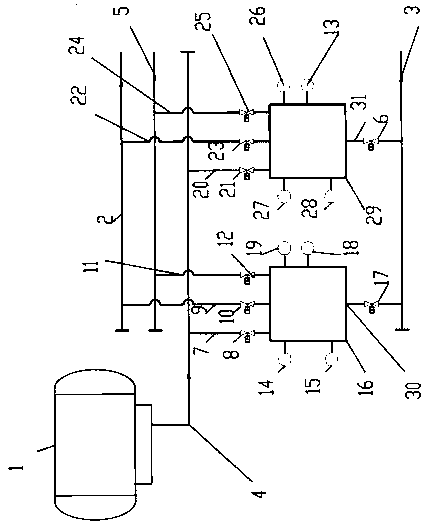

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

[0015] A vacuum equipment volumetric self-flowing continuous sewage discharge system, comprising a vacuum equipment 1, a first sewage discharge closed header 16 and a second sewage discharge closed header 29, the vacuum equipment 1 is provided with a sewage receiving main pipe 4, and a sewage receiving main pipe 4 The sewage inlet pipeline 7 of the first sewage closed header is connected with the first sewage closed header 16, and the first electromagnetic valve 8 is arranged on the sewage inlet pipeline 7 of the first sewage closed header, and the first sewage closed header 16 The bottom end of the first sewage discharge pipe 30 communicates with the sewage effluent main pipe 3. A fourth electromagnetic valve 17 is arranged on the first sewage discharge pipe 30, and a second solenoid valve 17 is arranged on the top of the first sewage discharge airtight header 16 respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com