Hydraulic-disassembly cylindrical interference connection structure and assembly/disassembly method

A cylindrical surface and hydraulic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that the cylindrical surface should not be disassembled many times, and achieve the effect of novel structure, protection of the joint surface, and avoidance of scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

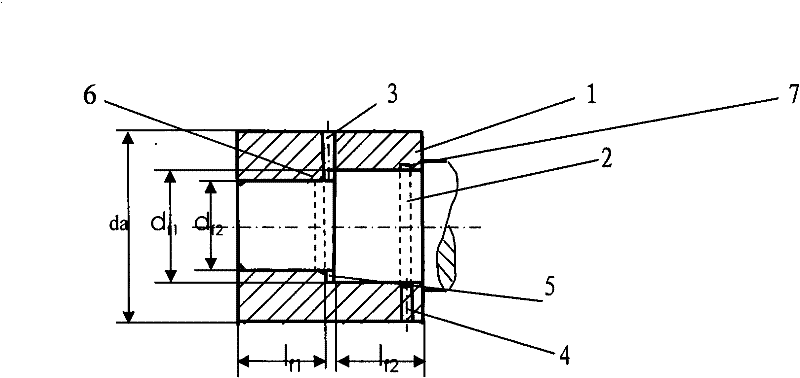

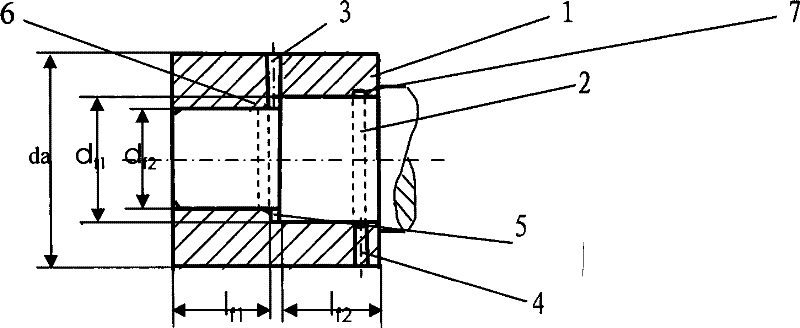

[0019] refer to figure 1 , a structure for hydraulically dismantling cylindrical surface interference connections, consisting of a containing part 1 and a contained part 2, the containing part 1 is a stepped inner cylindrical hole, and the contained part 2 is a stepped outer cylindrical shaft matching the shape of the containing part, containing Part 1 and contained part 2 cooperate with the distance between the shoulder end faces to form a hydraulic oil chamber 5. The containing part 1 is provided with a dismounted hydraulic oil inlet hole 3 that communicates with the hydraulic oil chamber 5. When the containing part or the contained part matches the shoulder There is a lubricating oil groove on one side of the end face.

[0020] The step of the ladder is set at the bisection of the matching length, so that the matching lengths of the two cylindrical surfaces are equal. The distance between the hydraulic oil cavity between the matching shoulder end surface of the containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com