Contact module housing, contact module and optical fiber connector

A contact and connector technology, applied in the direction of coupling of optical waveguides, can solve the problems of increasing the plug insertion speed, the plug contact does not have the function of on-site removal and removal, and increasing the size of the plug, so as to achieve the effect of on-site disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

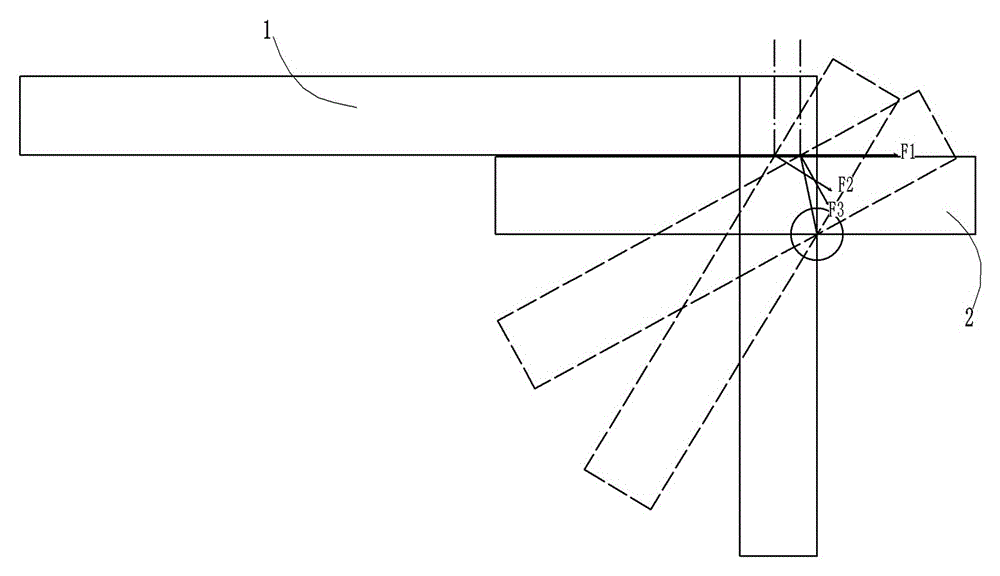

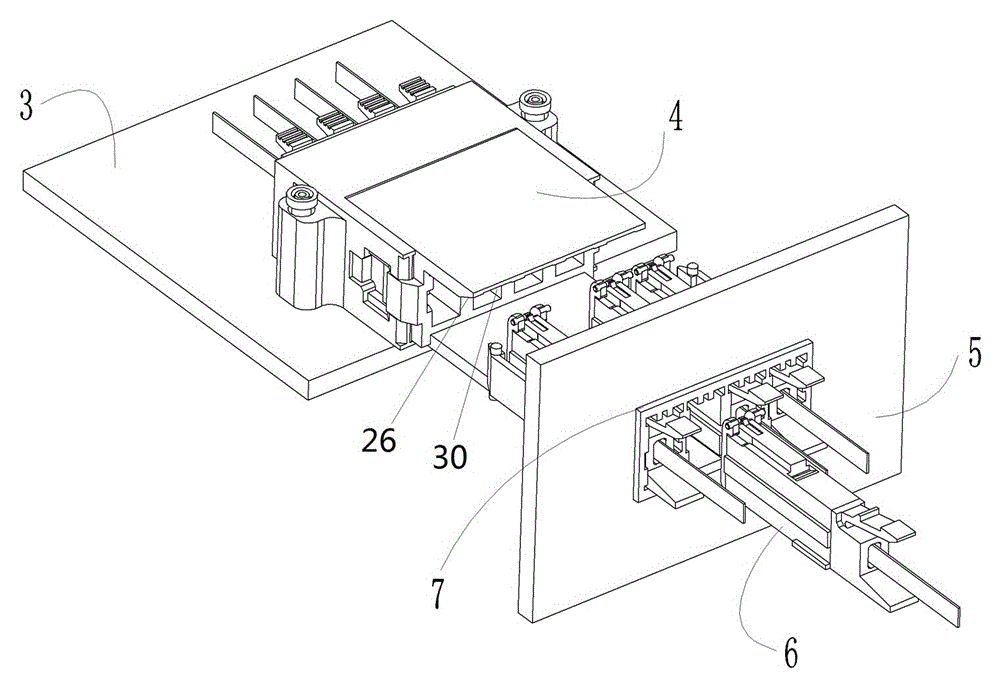

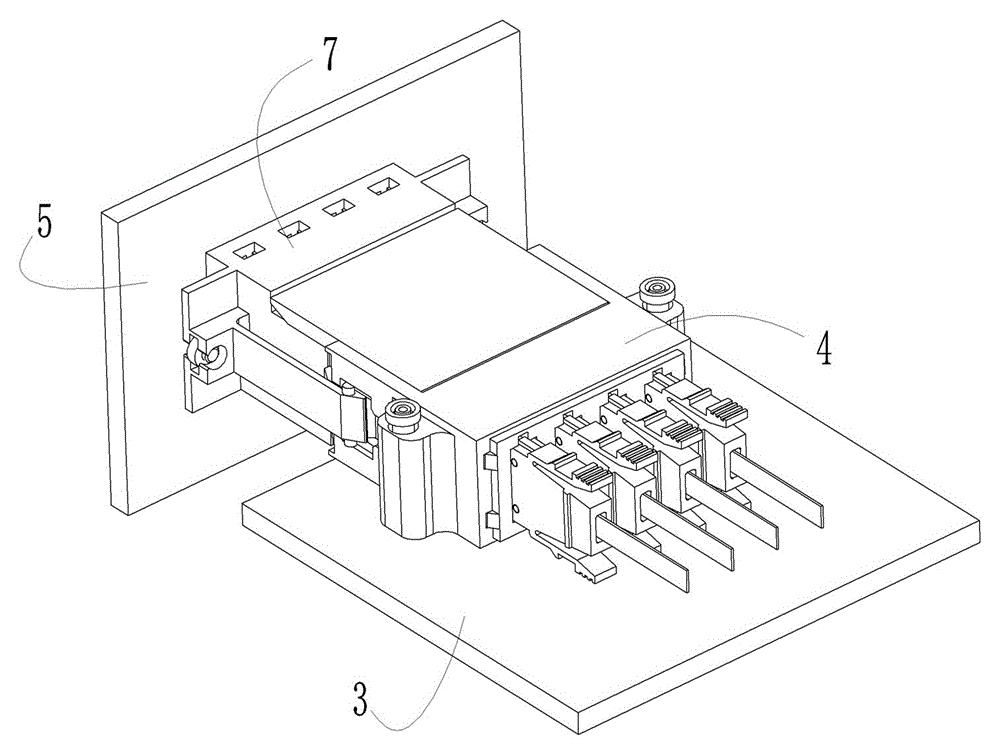

[0036] Examples of fiber optic connectors are Figure 2~12 As shown: the optical fiber connector in the present invention is an optical fiber receptacle 7 , which needs to be mated with an adapted optical fiber connector, that is, an optical fiber plug 4 in actual use. During use, the optical fiber socket is installed on the backboard 5 of the cabinet, and the optical fiber plug is installed on the sub-board 3 of the cabinet. The fiber optic socket is a combined socket with at least two socket contact modules 6, and the fiber optic plug is a combined plug with at least two plug contact modules. The optical fiber socket includes a socket connector frame 7 and four socket contact modules 6. The socket connector frame is used for installing the socket contact module and fixing it to the backplane. Module mounting hole 21, the shape of the module mounting hole is a rectangle, the left and right sides of the module mounting hole are provided with guide keyways 23 extending along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com