Cannon barrel axial line positioner

A positioning device and artillery barrel technology, applied in the field of military weapons, can solve problems such as non-cylindrical surfaces, non-parallel, non-coincidental, etc., and achieve the effects of improving measurement accuracy, reducing errors, and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

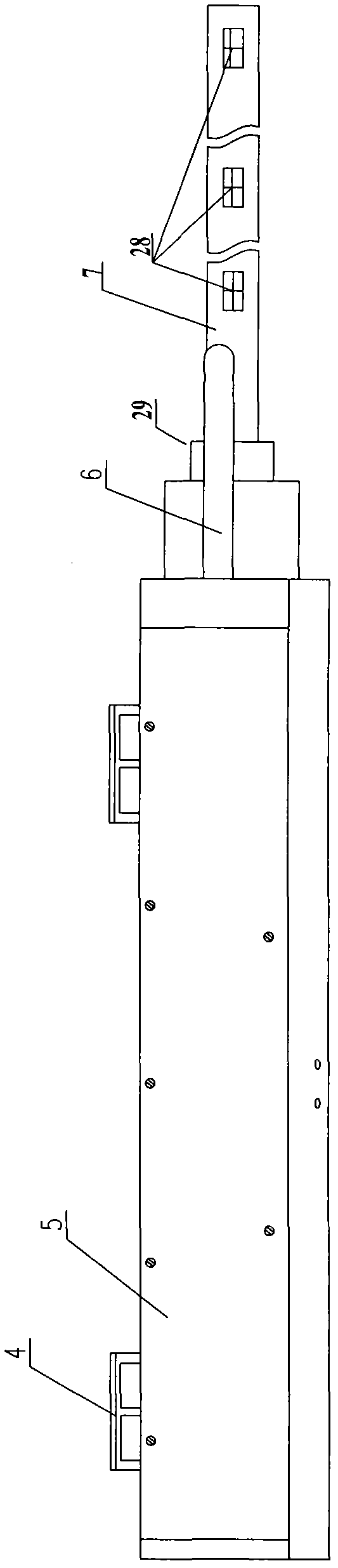

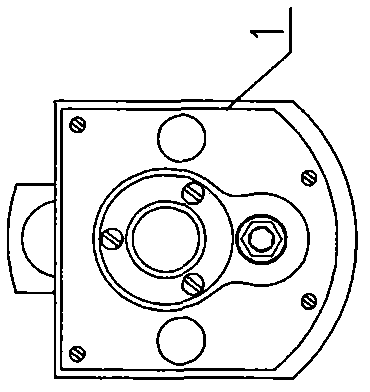

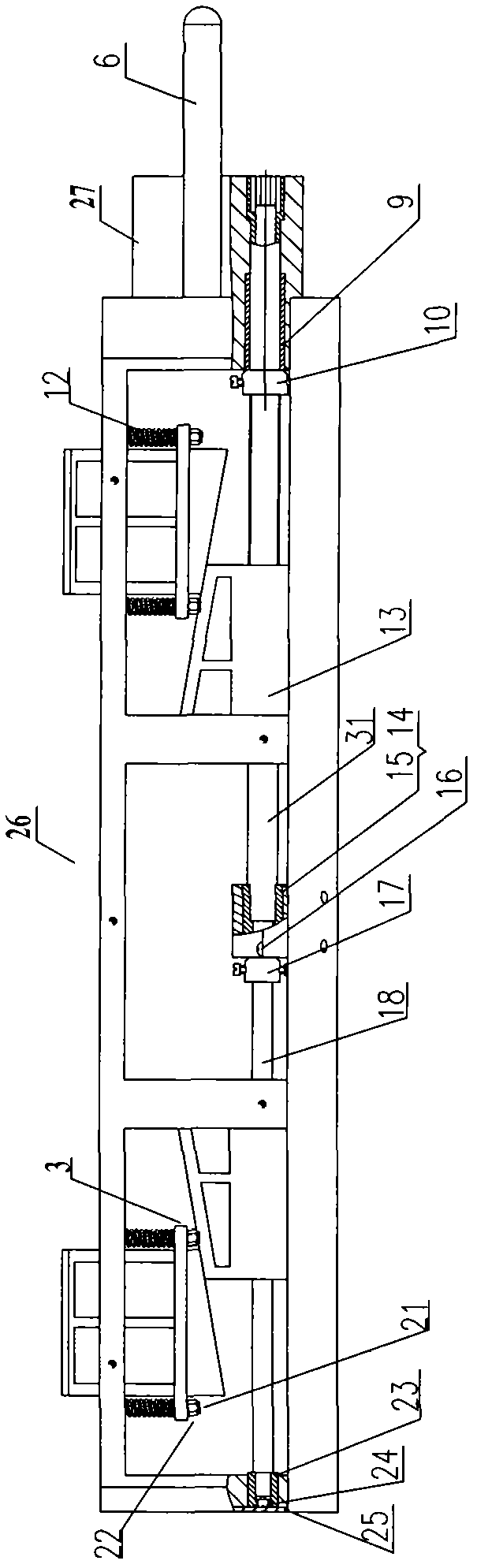

[0052] figure 1 Shown is a gun barrel axis positioning device, which includes an axis positioning frame 26 and an axis extension rod 7. The axis positioning frame 26 can be in surface contact with the barrel inner wall through a radial lifting adjustment mechanism in the barrel and the distance between the two work close with.

[0053] refer to figure 2 -- Figure 4 The front end of axis positioning frame 26 has the positioning seat 27 of axis extension bar 7, and also has the rotating rod 6 for adjusting axis positioning frame 26 in the barrel. The positioning seat 27 is provided with a mounting hole where the central axis coincides with the axis of the barrel, and the axis extension rod 7 has a structural reference Figure 16 , is a hollow aluminum structure, is fixed on the positioning seat 27 through the mounting hole and is located outside the barrel, and is provided with marking points 28 on the outer wall of the axis extension rod 7. Marking is no different.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com