Curvature measuring instrument

A measuring instrument and curvature technology, applied in the field of measuring instruments, can solve problems such as inaccurate bending data, difficult quantitative detection, and inaccuracy, and achieve the effects of accurate measurement, convenient manufacturing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention will be described in further detail below in conjunction with the accompanying drawings.

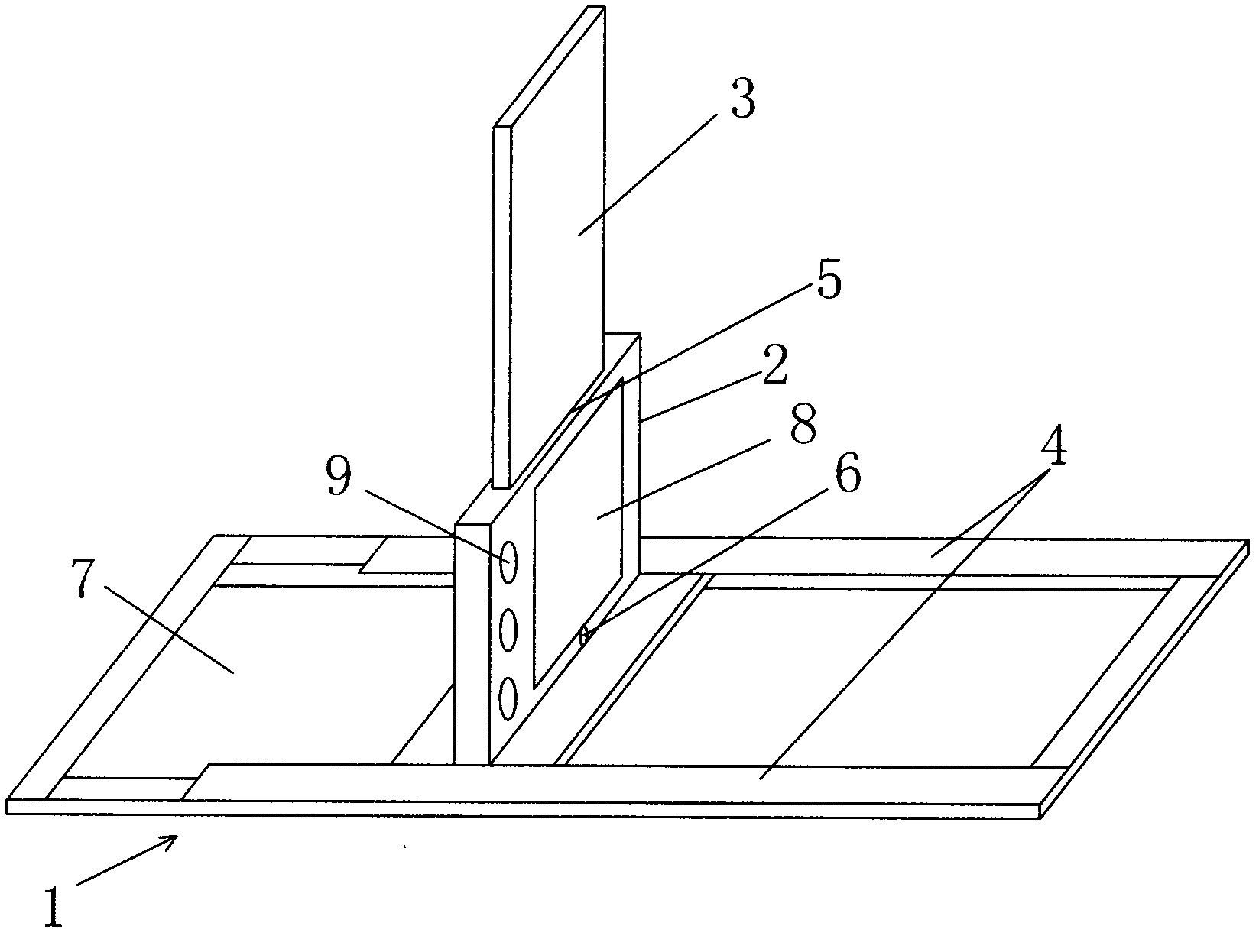

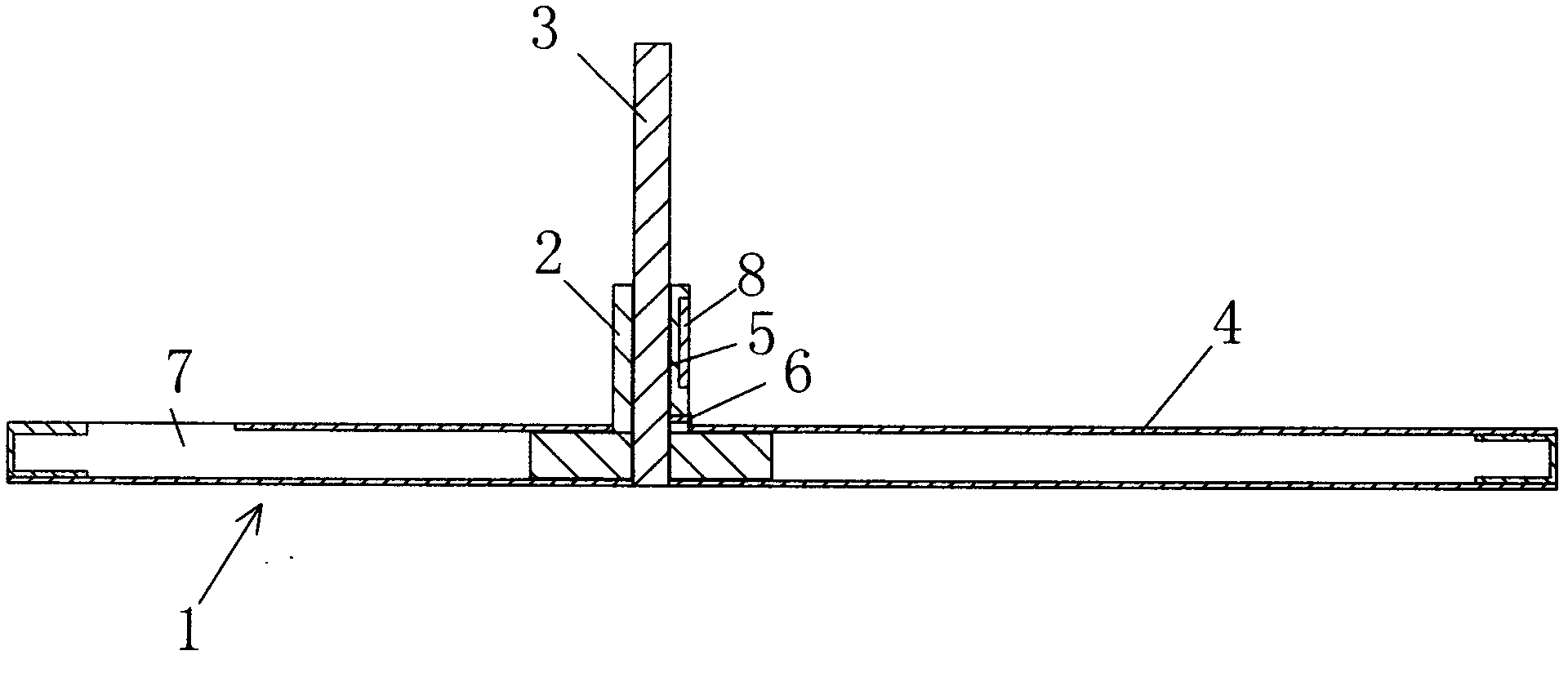

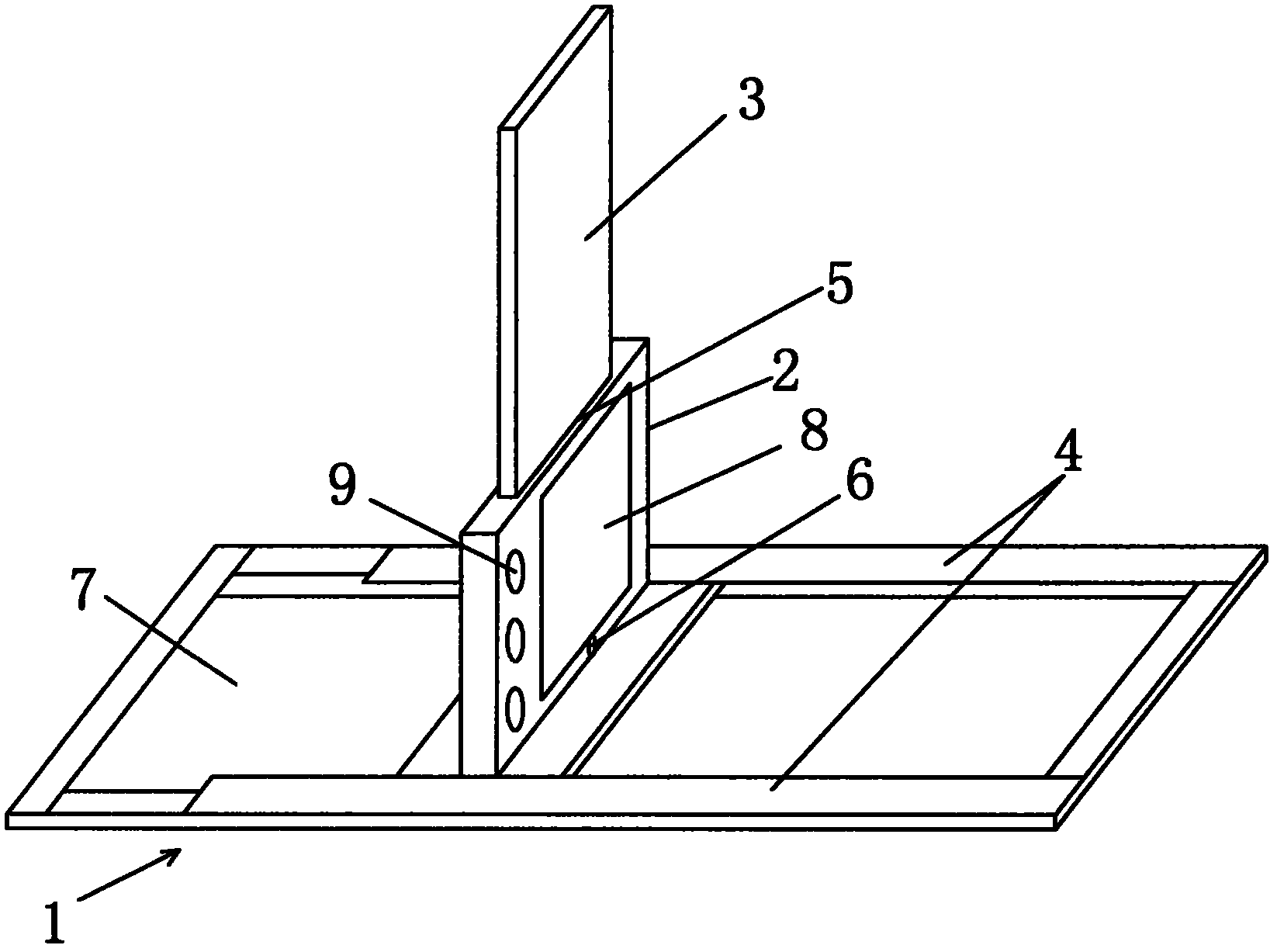

[0012] Such as figure 1 and figure 2 As shown, a curvature measuring instrument includes a frame 1, a sliding scale base 2 and a vernier caliper 3, the frame 1 includes two parallel guide rails 4, the sliding scale base 2 is slidingly connected with the guide rails 4, and the sliding scale base 2 is provided with a shaft The guide groove 5, the vernier caliper 3 is inserted into the guide groove 5 and runs through the upper and lower sides of the sliding scale base 2, and the vernier caliper 3 and the sliding scale base 2 are locked by screws 6. One end of the frame 1 is provided with an inlet and outlet 7 of a slide base 2 . The slide base 2 is provided with a display screen 8 and control buttons 9, wherein the control buttons 9 include a switch button, a reset button and a metric / imperial conversion button, and the control button 9 is placed on the side of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com