Wrinkle reduction in uncured composite laminates

A wrinkle, transducer head technology, applied in the field of composite laminate manufacturing, can solve the problems of less effective, time-consuming removal of wrinkles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

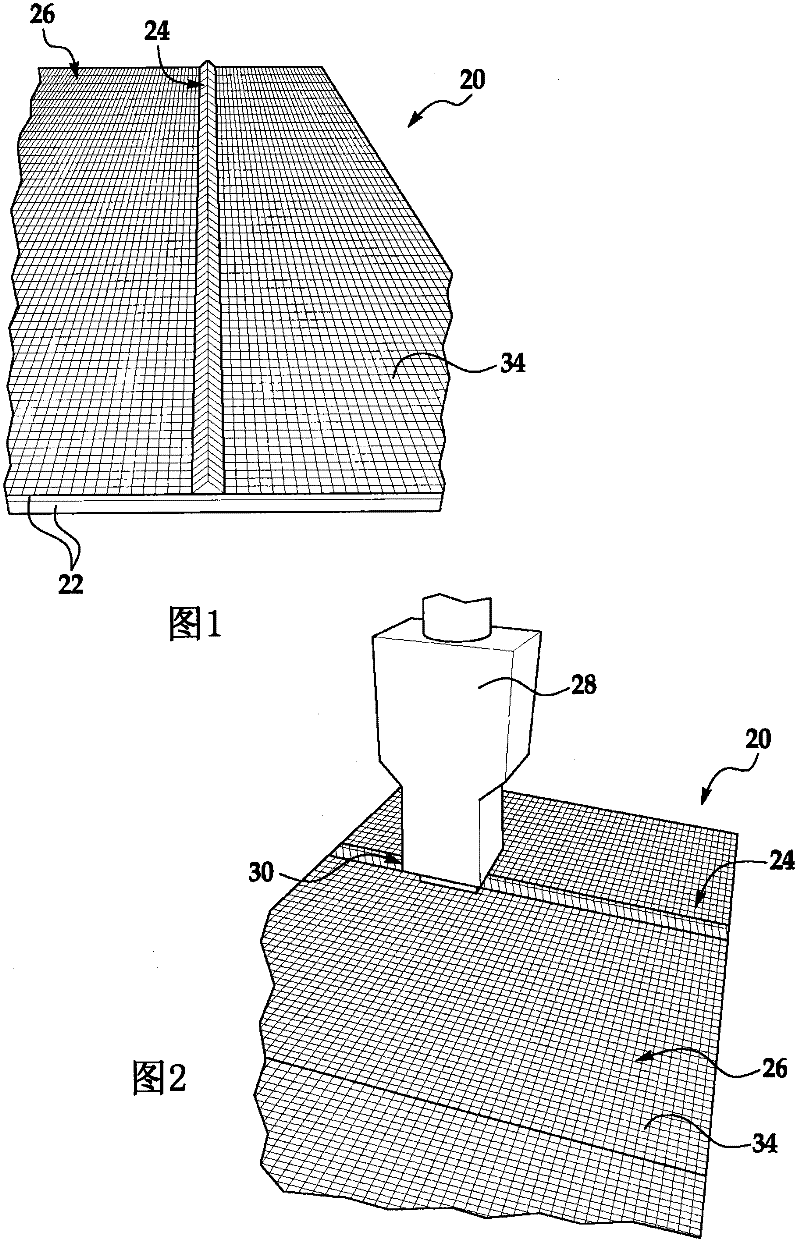

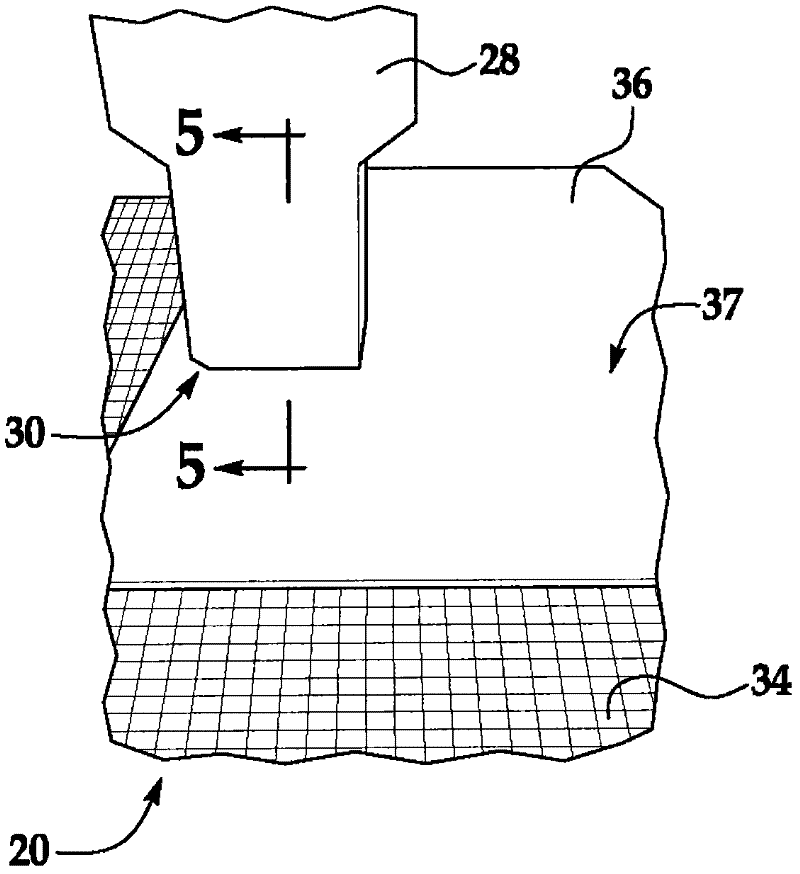

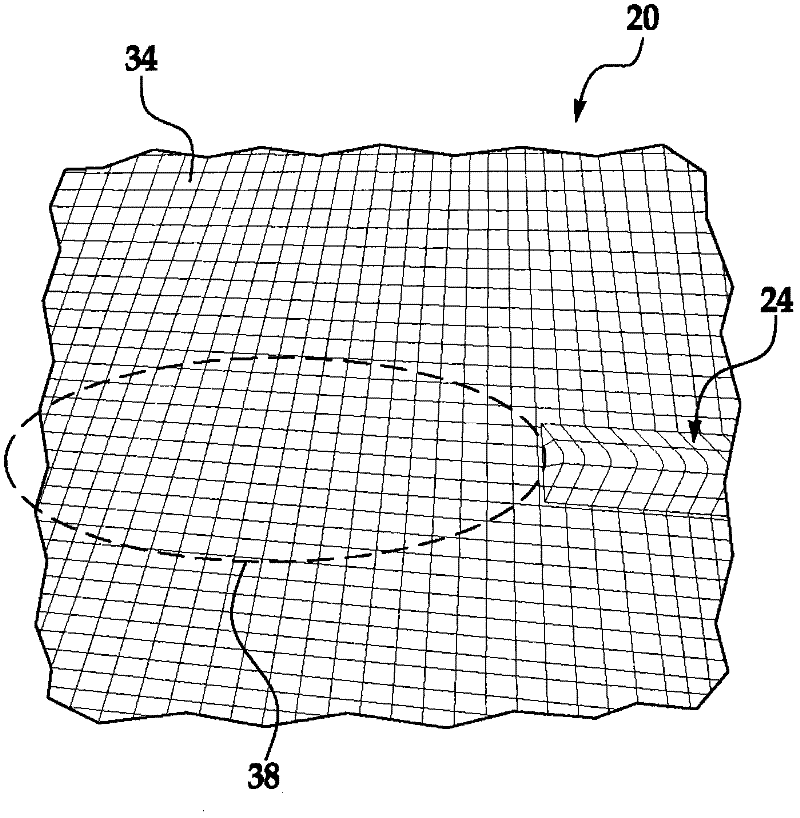

[0065] reference figure 1 The uncured composite laminate material 20 includes a plurality of sheets 22 of fiber-reinforced prepreg material, such as, but not limited to, reinforced carbon fibers supported in an epoxy resin matrix. The reinforcing fibers in the sheet 22 may be woven or knitted and may have any of a variety of fiber orientations. In some cases, some of the sheets 22 may include unidirectional fibers pre-impregnated with resin.

[0066] The laminate material 20 may include, for example, and is not limited to, a layup material 26 formed on a tool (not shown) for forming the laminate material 20 into a desired composite structure. During the layup process-where the sheet 22 is continuously stacked on a tool (not shown), one or more folds 24-also called buckles or buckling-can be on the sheet 22 Some or all of them. In some cases, the wrinkles 24 may only be present in the top sheet of the sheet of laminate 20.

[0067] The wrinkles 24 may be caused by, without limita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com