Blade with adaptive twist and rotor with such a blade

一种自适应、桨叶的技术,应用在旋翼机、与风向一致的的风力发动机、应用等方向,能够解决桨叶重量增大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

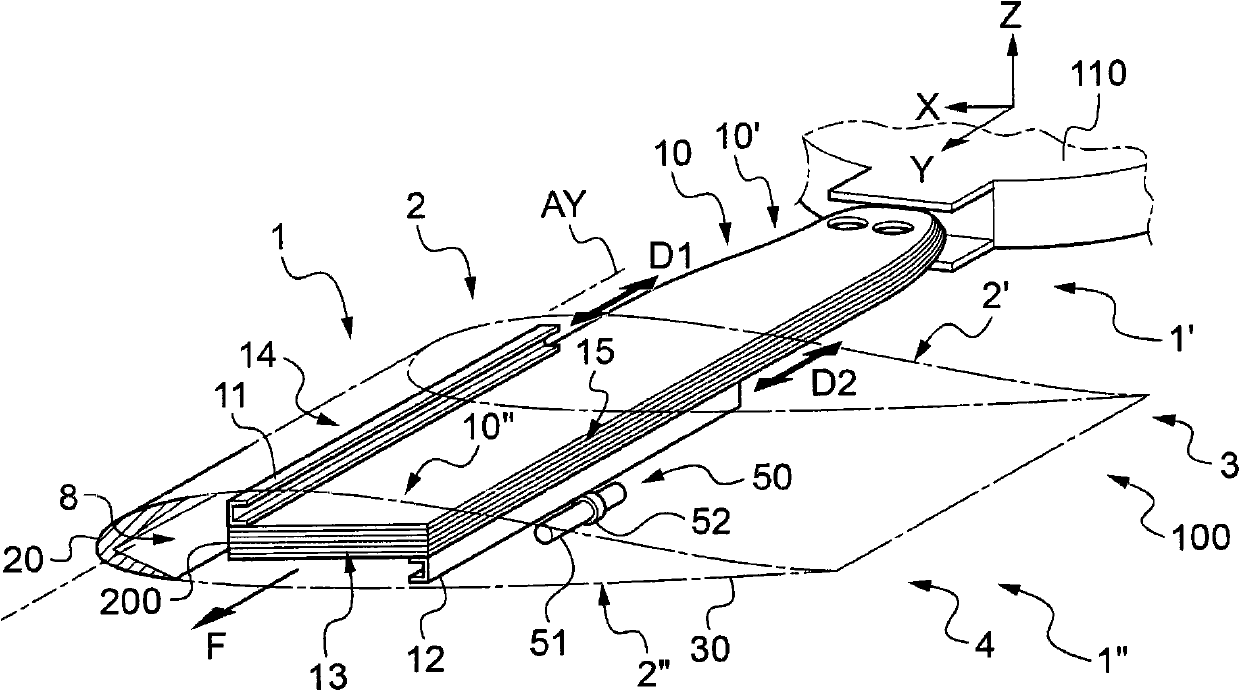

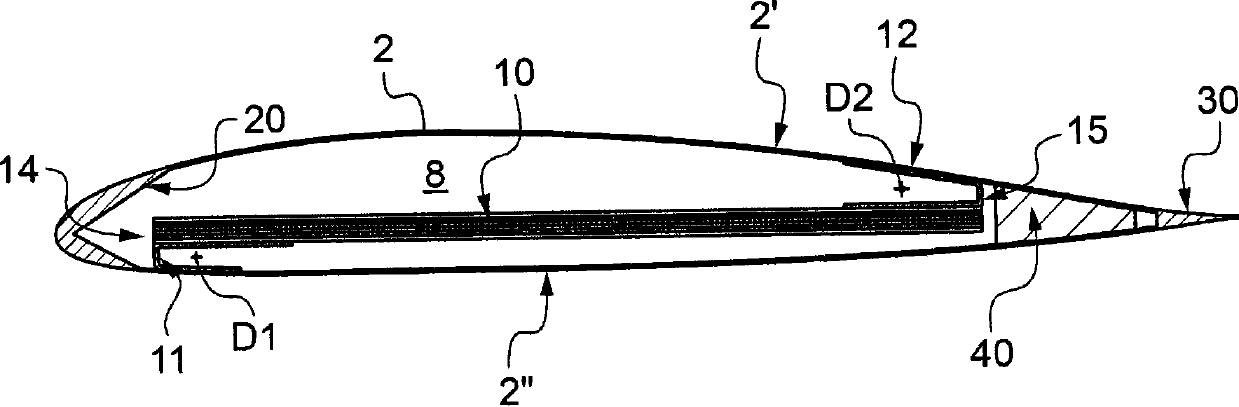

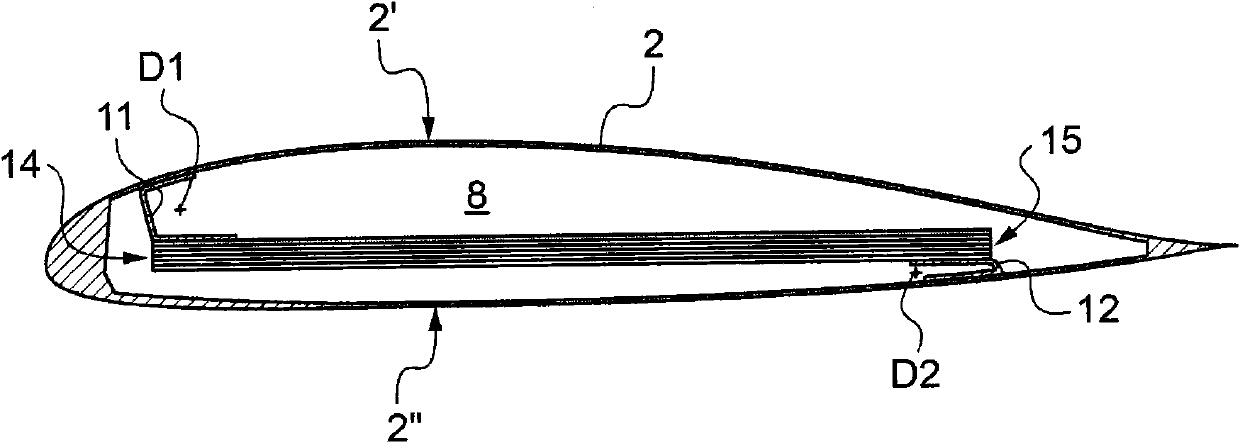

[0085] Elements appearing in more than one figure are provided with the same reference numerals in each figure.

[0086] The three mutually orthogonal directions are labeled X, Y, and Z, which can be found in figure 1 and 2 see in.

[0087] The direction X is called the transverse direction. The term "width" refers to the transverse dimension of the blade along said transverse direction X.

[0088] The other direction Y is called the reference direction, ie the case where the blade extends along said direction Y. Both the so-called "longitudinal" direction and the direction of the axis about which the pitch of the blade changes are parallel to this reference direction.

[0089] Finally, the third direction Z is vertical and corresponds to the height dimension of the described structure. The term "thickness" then refers to the vertical dimension along this vertical direction.

[0090] figure 1 is a schematic diagram of the blade 1 of the present invention. The blade 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com