Direct drive type hydraulic variable pitch controlling mechanism for wind power generator

A wind turbine and control mechanism technology, applied in the control of wind turbines, wind turbines, wind power generation, etc., can solve the problems of complex hydraulic circuits, low reliability, and no redundant control, so as to achieve reliable control and simplified hydraulic pressure. circuit, the effect of reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

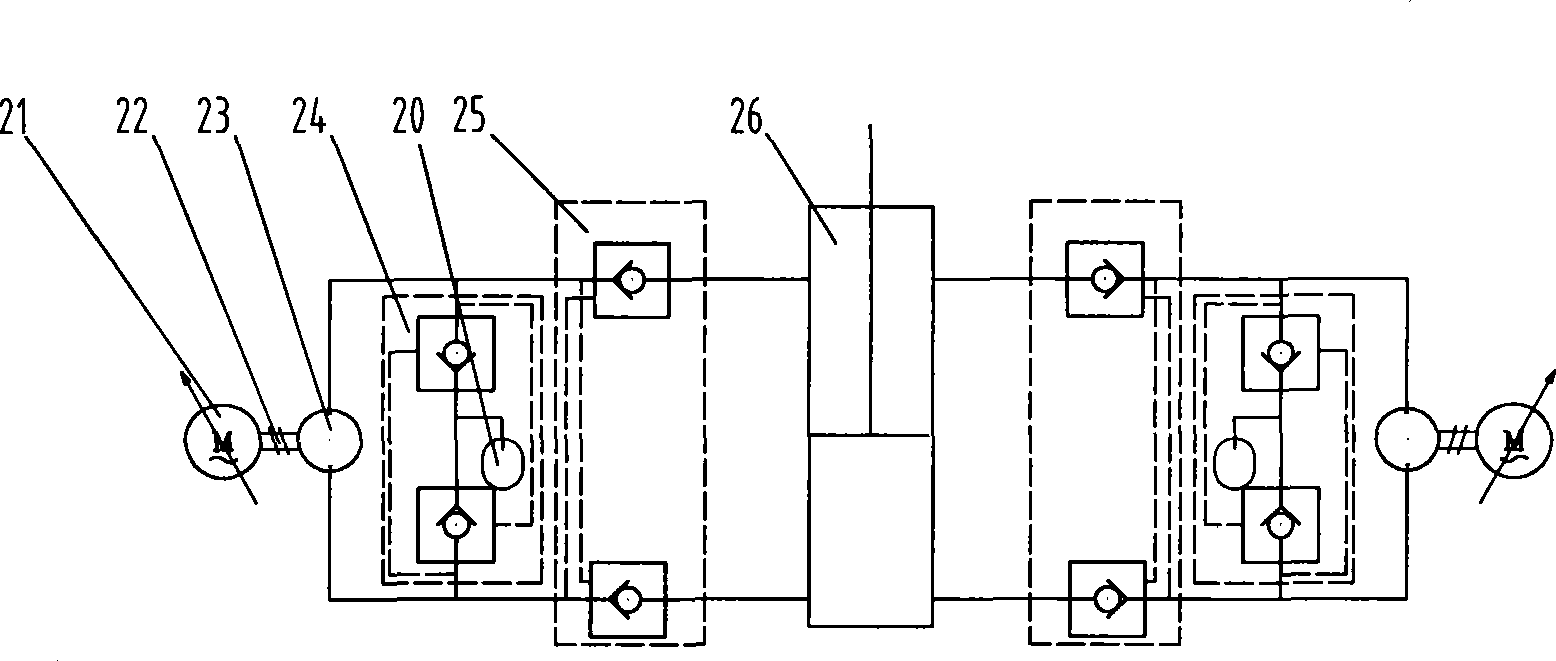

[0009] Specific implementation mode one: combine image 3 Describe this embodiment, the direct-drive hydraulic pitch control mechanism in this embodiment consists of a closed oil tank 20, an AC servo motor 21, a shaft coupling 22, a bidirectional quantitative pump 23, an oil replenishment valve 24, and a bidirectional hydraulic lock 25 It is composed of variable pitch hydraulic cylinder 26; the power output shaft of AC servo motor 21 is connected with the power input shaft of bidirectional quantitative pump 23 through coupling 22, and the AC servo motor 21 clockwise or counterclockwise after receiving the voltage signal of the variable pitch controller. The clockwise rotation drives the two-way quantitative pump 23 to rotate, outputs pressure oil to the variable pitch hydraulic cylinder 26, and pushes the piston rod of the hydraulic cylinder to move, thereby adjusting the pitch angle of the blades to meet the optimal working condition of the generator; When the feedback signal...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination Figure 4 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the normally open two-position two-way solenoid valve 28, the normally closed two-position two-way solenoid valve 29 and the hydraulic accumulator 31 are added; the pitch hydraulic cylinder 26 The rod chamber of the hydraulic cylinder 26 communicates with the closed oil tank 20 through the normally open two-position two-way solenoid valve 28; the rodless chamber of the variable pitch hydraulic cylinder 26 communicates with the hydraulic accumulator 31 through the normally closed two-position two-way solenoid valve 29; The normally open two-position two-way solenoid valve 28 and the normally closed two-position two-way solenoid valve 29 are energized during pitch adjustment and remain closed. At this time, the other parts of the direct-drive hydraulic pitch control mechanism work in the same way as the specific Imple...

specific Embodiment approach 3

[0011] Specific implementation mode three: combination Figure 4 Describe this embodiment, the difference between this embodiment and the specific embodiment 1 or 2 is that a manual shut-off valve 27 is added, and the three oil ports of the manual shut-off valve 27 are connected with the oil inlet and outlet ports of the closed oil tank 20 and the pitch hydraulic pressure respectively. The rod chamber of cylinder 26 is connected with the oil inlet and outlet of the rodless chamber. The manual stop valve 27 is usually closed, and the two cavities of the pitch hydraulic cylinder 26 and the closed oil tank 20 are locked. When it is necessary to maintain the direct-drive hydraulic pitch mechanism, the manual cut-off valve 27 can be opened to connect the two cavities of the pitch hydraulic cylinder 26 with the closed oil tank 20, and the pressure in the pitch hydraulic cylinder 26 can be removed. , the pitch hydraulic cylinder 26 can be maintained. Other compositions and connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com