Spot-welding positioning mechanism for process gasket of protector

A process gasket and spot welding positioning technology, which is applied in the direction of manufacturing tools, welding equipment, resistance welding equipment, etc., can solve the problem of affecting the product quality of the three-metal sheet combination, the process gasket cannot be positioned in the radial direction, and the accuracy of positioning is affected, etc. problem, to achieve the effect of simple structure, easy placement and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

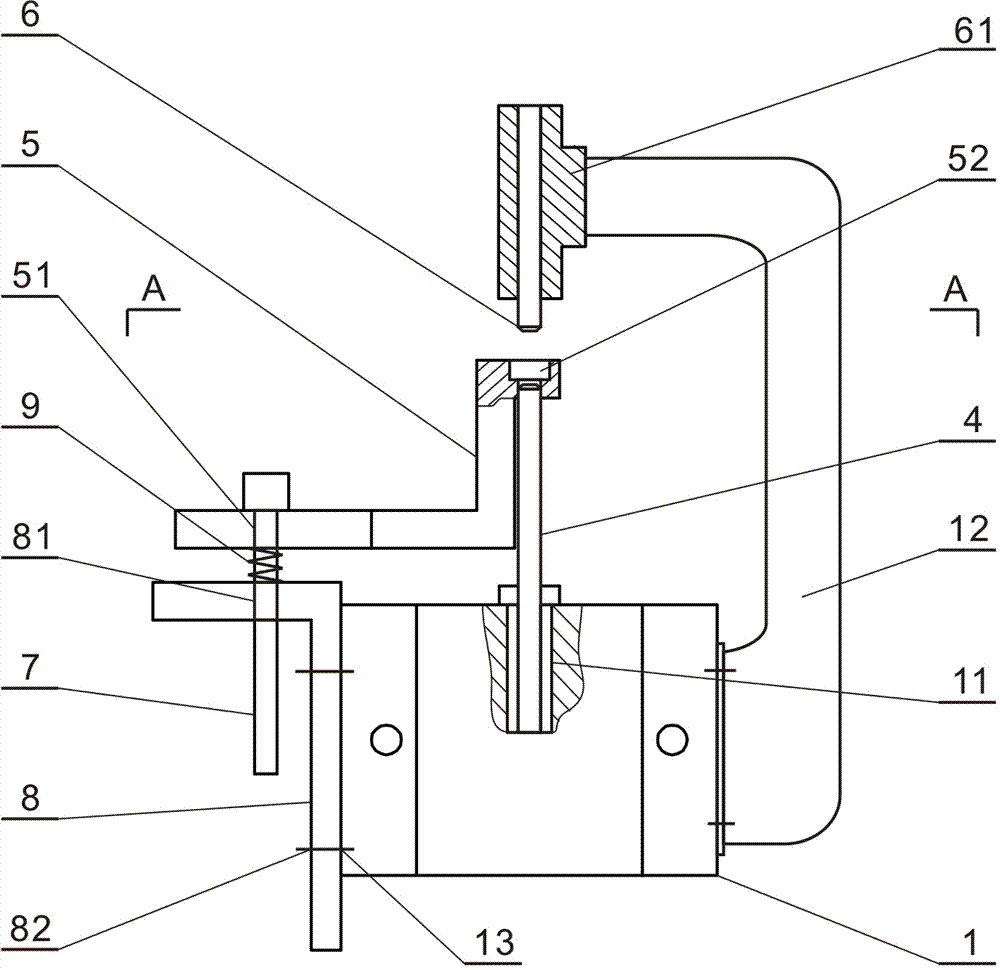

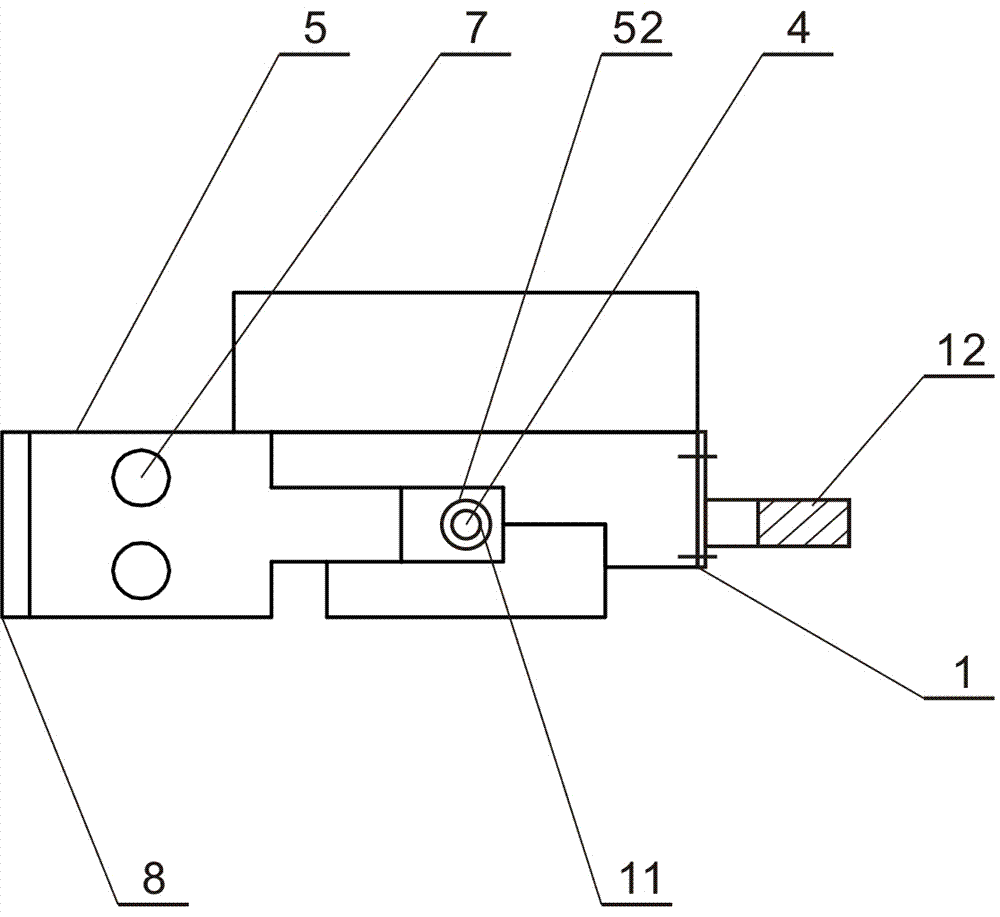

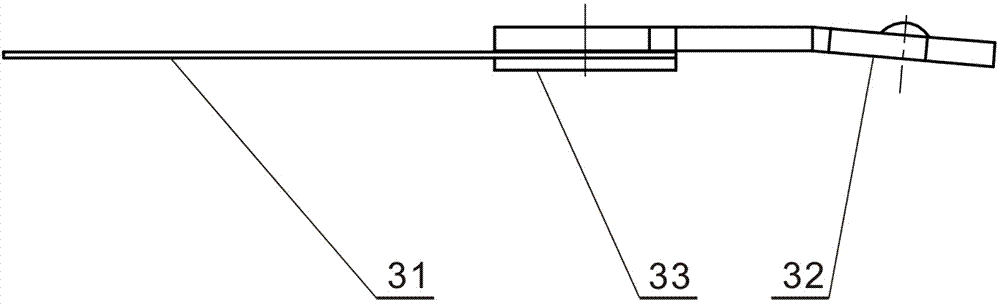

[0011] refer to figure 1 , figure 2 , the present invention includes a base 1, a lower electrode 4, a positioning plate 5, an upper electrode 6, a guide rod 7, a bracket 8 and a spring 9, the base 1 is a rectangular body, the middle part is provided with an electrode groove 11, and one side is provided with a There is a connecting arm 12 and a bracket seat 13 on the other side. The positioning plate 5 is a "Z" shaped plate, one end of which is provided with a placement cavity 52, and the other end is provided with two first guide rod holes 51 side by side. The upper electrode 6 is provided with an electrode moving sleeve 61, and the bracket 8 is an "L"-shaped plate, with two second guide rod holes 81 arranged side by side on one surface, and several mounting holes 82 arranged on the other surface; The lower electrode 4 is vertically arranged in the electrode groove 11 of the base 1, the guide rod hole 81 of the bracket 8 is vertically upward and fixedly connected with the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com