Compact tensioner with sustainable damping

A technology of tensioning device and damping mechanism, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of misalignment of pulleys, high manufacturing cost and damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

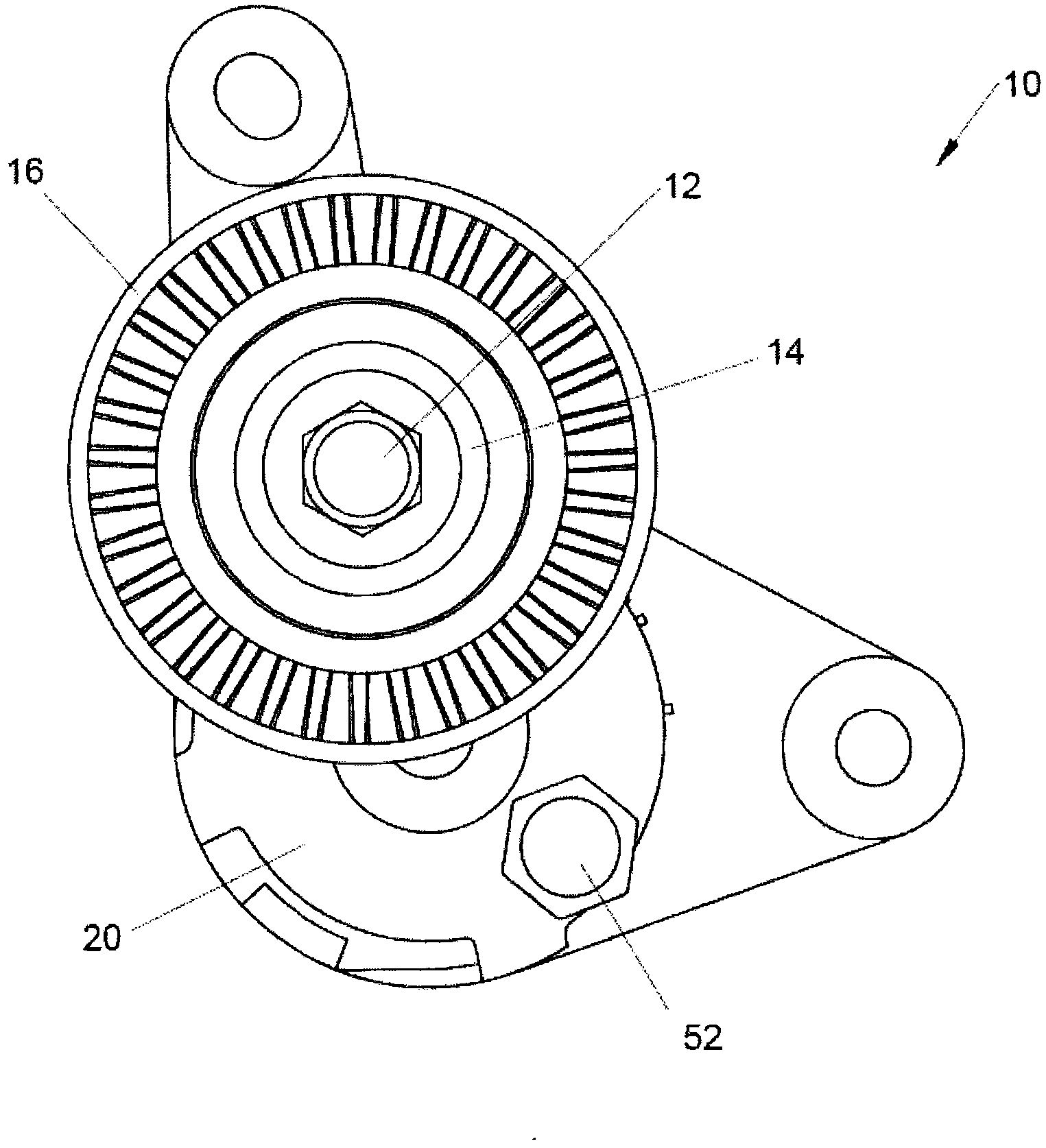

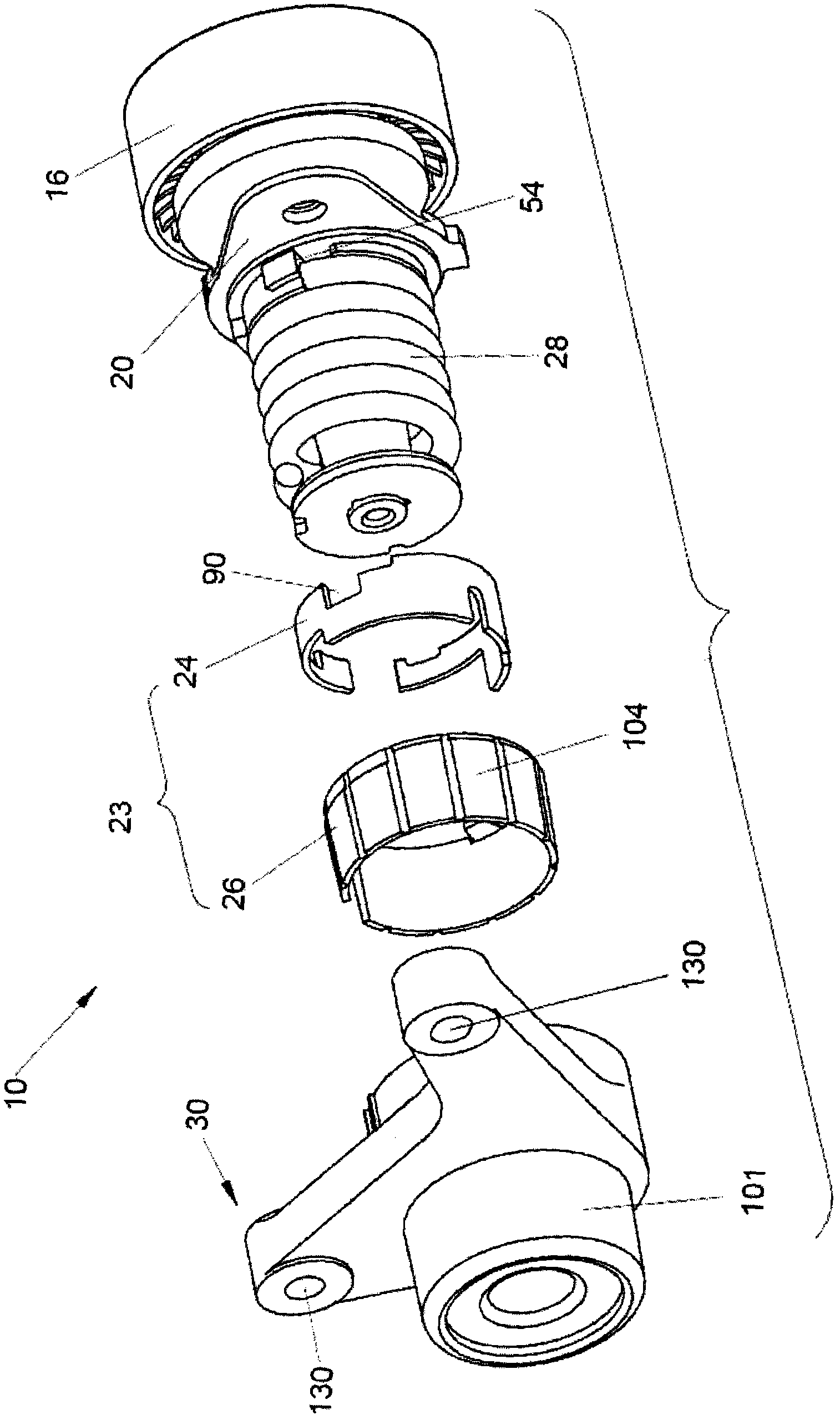

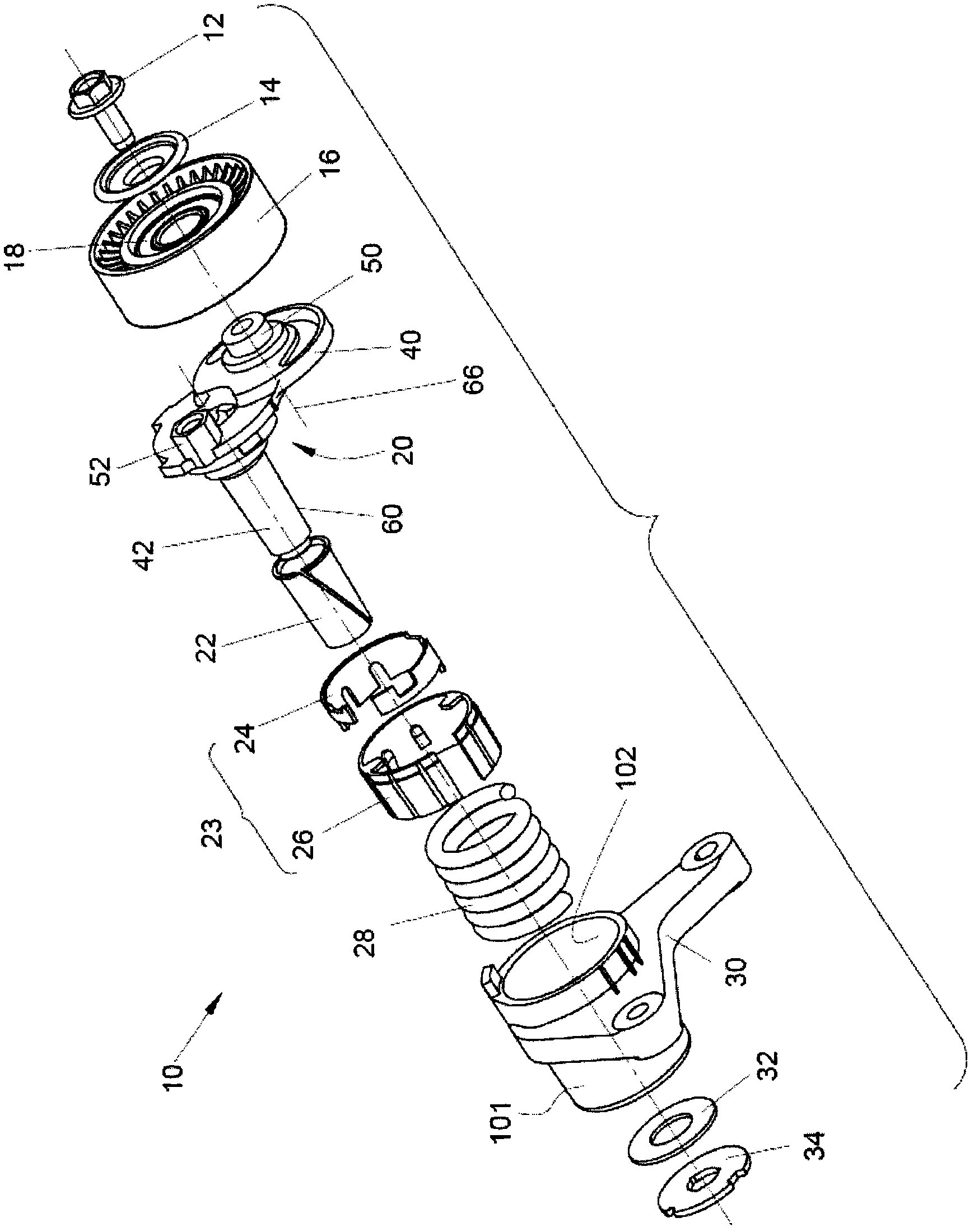

[0029] Refer to the attached Figure 1 to Figure 3, a tensioner assembly constructed in accordance with the teachings of the present disclosure is indicated generally by reference numeral 10 . The tensioner assembly 10 may include a fastener 12, a boot 14, a wheel 16, a bearing 18, an arm 20, a pivot bushing 22, a damping mechanism 23 (which may include a bushing 24 and a damping element 26), Spring 28 , bracket or base 30 , thrust washer 32 and thrust plate 34 . Fastener 12, boot 14, bearing 18, and thrust washer 32 are of generally conventional construction and need not be discussed in detail herein.

[0030] refer to Figure 2 to Figure 5 , the arm 20 may be integrally formed in a suitable process such as die casting, and may define an arm member or portion 40 and a stem member or portion 42 . Arm portion 40 may include bearing mount 50 , lift member 52 , spring reaction member 54 and spring support 56 , while stem portion 42 may include rod 60 . Bearing mount 50 may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com