Novel process for preparing masonry material by waste solidification treatment

A technology of solidification treatment and new process, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems such as the troublesome process of domestic waste pretreatment, the inability to deal with construction waste, and the long processing process, etc. Achieve the effect of low cost, low investment and simplified steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described below in conjunction with embodiment and accompanying drawing.

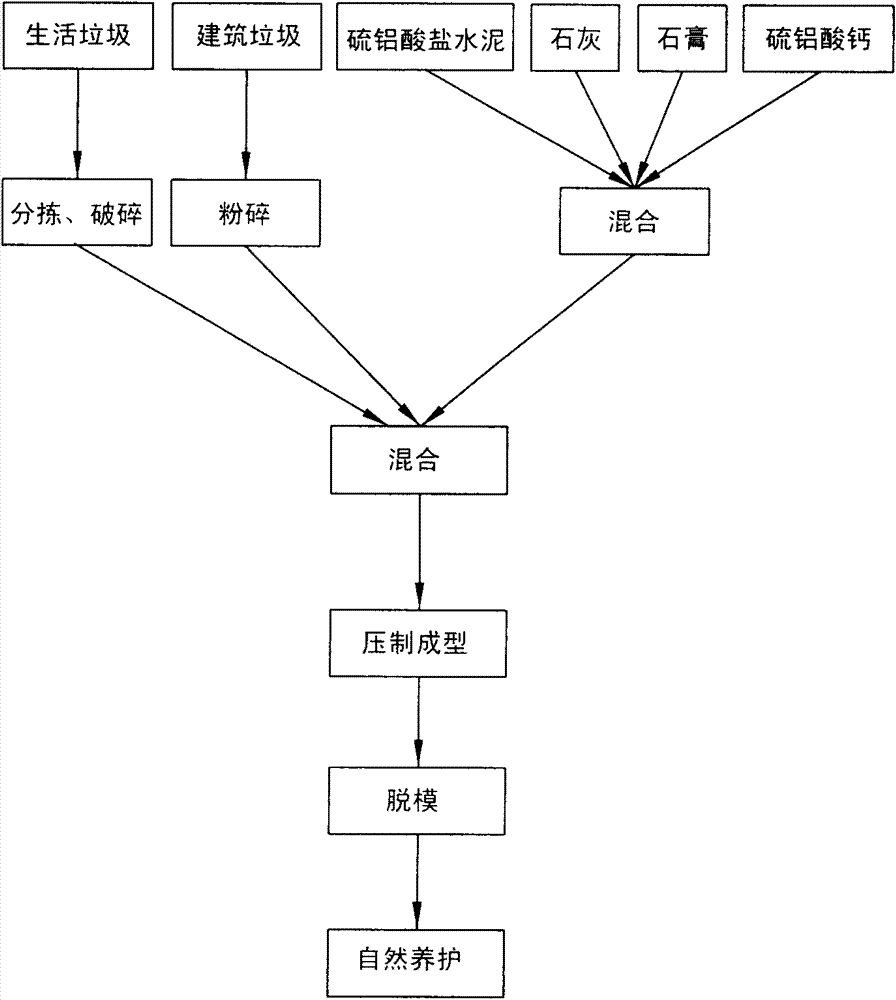

[0016] Referring to the accompanying drawings, the process steps of a specific embodiment of the present invention are as follows:

[0017] a. Sorting domestic garbage, removing the contained plastics and metals, and breaking them into fragments with a maximum size of less than 5mm. The plastics mentioned mainly refer to plastic bags, waste plastic products, etc.;

[0018] b. Crush the large blocks in the construction waste into particles with the largest size less than 3mm;

[0019] c. Mix quicklime powder, sulphoaluminate cement, quick gypsum powder and calcium sulphoaluminate powder to form a coagulant. The parts by weight of each component of the coagulant are:

[0020] Quicklime powder 15, sulfoaluminate cement 12.5, quick gypsum powder 3, calcium sulfoaluminate powder 3.5,

[0021] The particle size of quicklime powder, raw gypsum powder and calcium sulfoa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com