Production device of high-strength fine-grain hot rolled ribbed steel bars and production process thereof

A hot-rolled ribbed steel bar and production equipment technology, applied in temperature control, metal rolling, etc., to achieve the effects of reducing production costs, strong product competitiveness, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

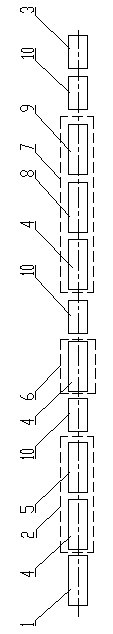

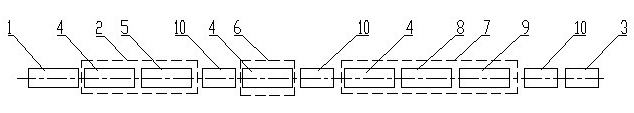

[0021] figure 1 It is a schematic diagram of the layout of the present invention, as shown in the figure: The high-strength fine-grained hot-rolled ribbed steel bar production equipment of this embodiment includes a billet pretreatment unit 1 and a low-temperature isothermal rapid rolling unit 2 which are sequentially arranged to form a rolling production line. As with the finished product processing unit 3, the billet pretreatment unit 1 of this embodiment is a continuous casting machine, which performs continuous casting and rolling, and the temperature loss of the rolled piece is small, and the energy saving effect is significant. The finished product processing unit 3 uses a cooling bed and bundled collection equipment. Of course, replacing the continuous casting machine with a heating device, directly heating the billet and sending it out, and replacing equipment such as a cooling bed with equipment such as a laying machine-air-cooled roller conveyor line can also achieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com