Follow-up oxygen lance nitrogen seal device

A technology of oxygen lance and nitrogen sealing, applied in the manufacture of converters, etc., can solve the problems of falling, poor sealing effect, loss of nitrogen sealing effect, etc., and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

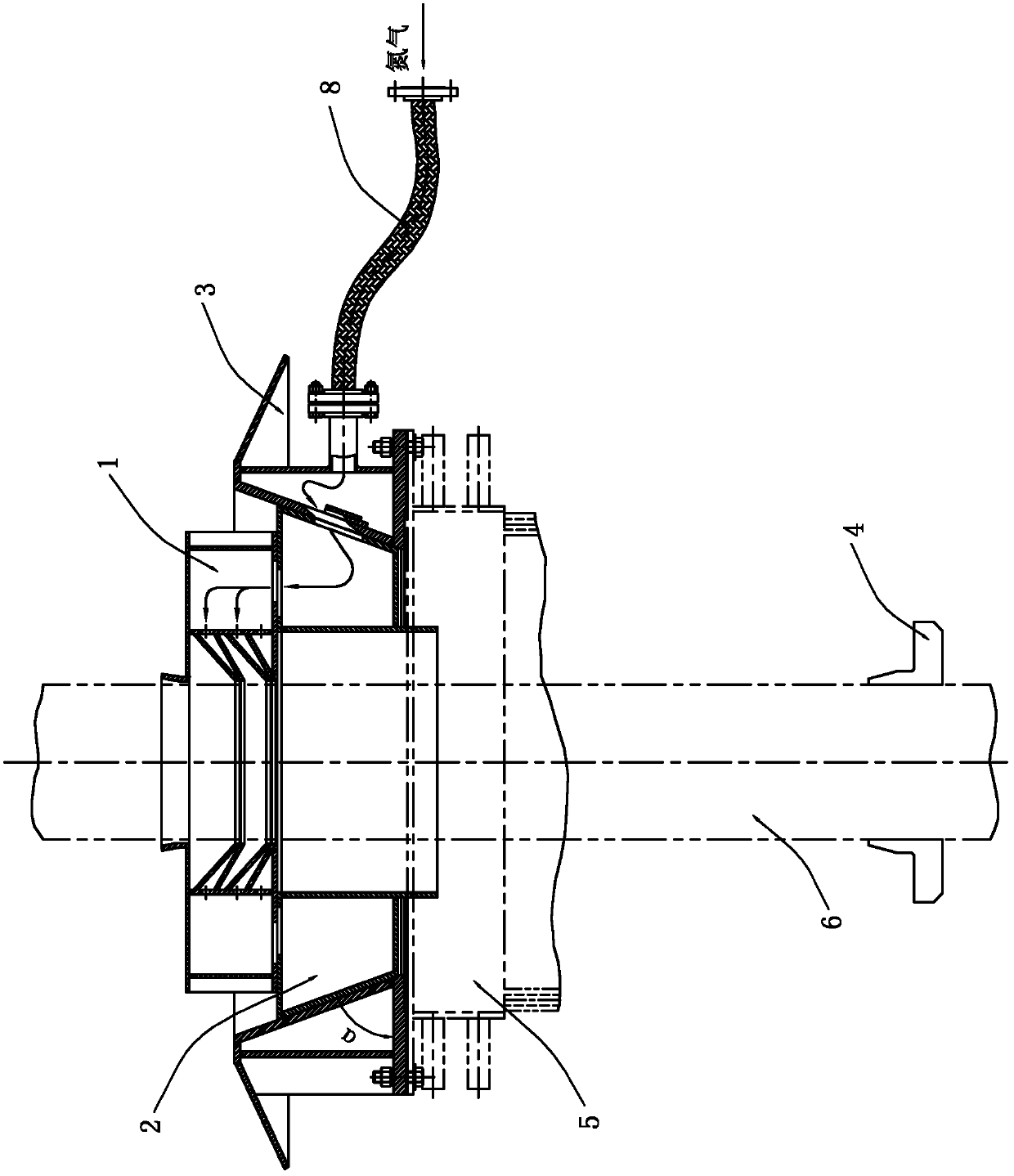

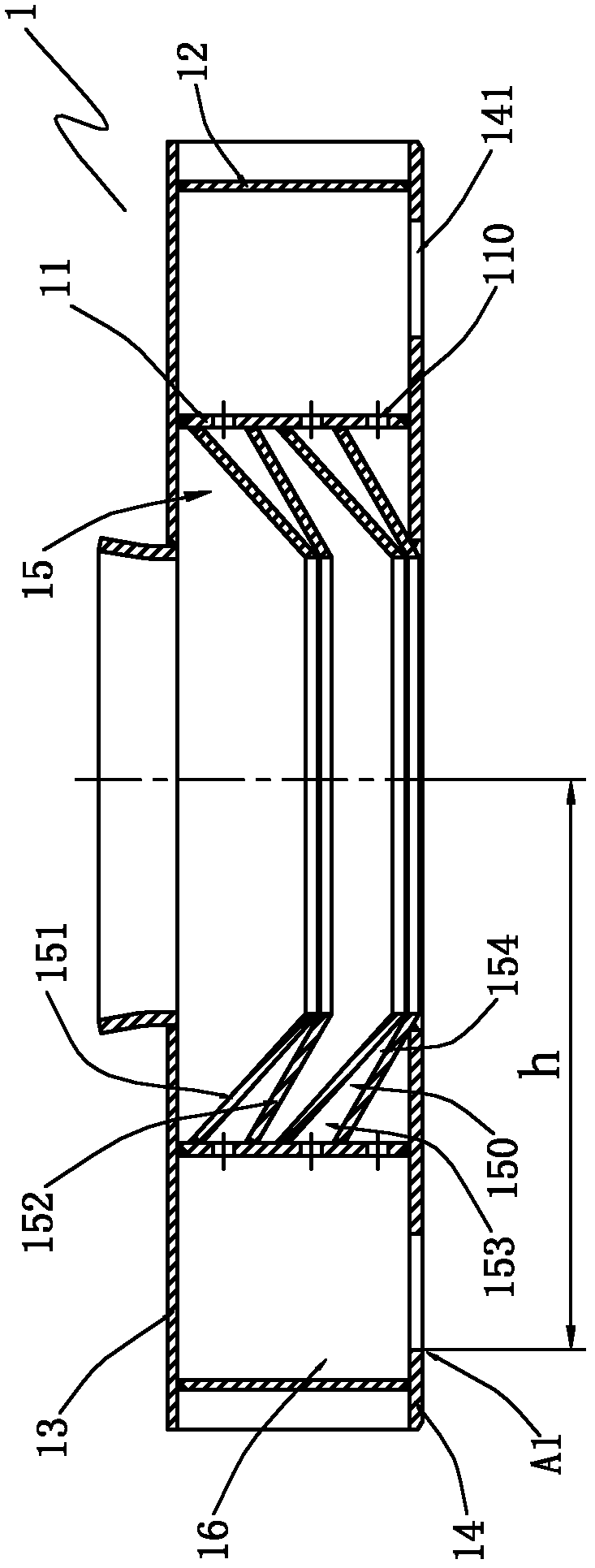

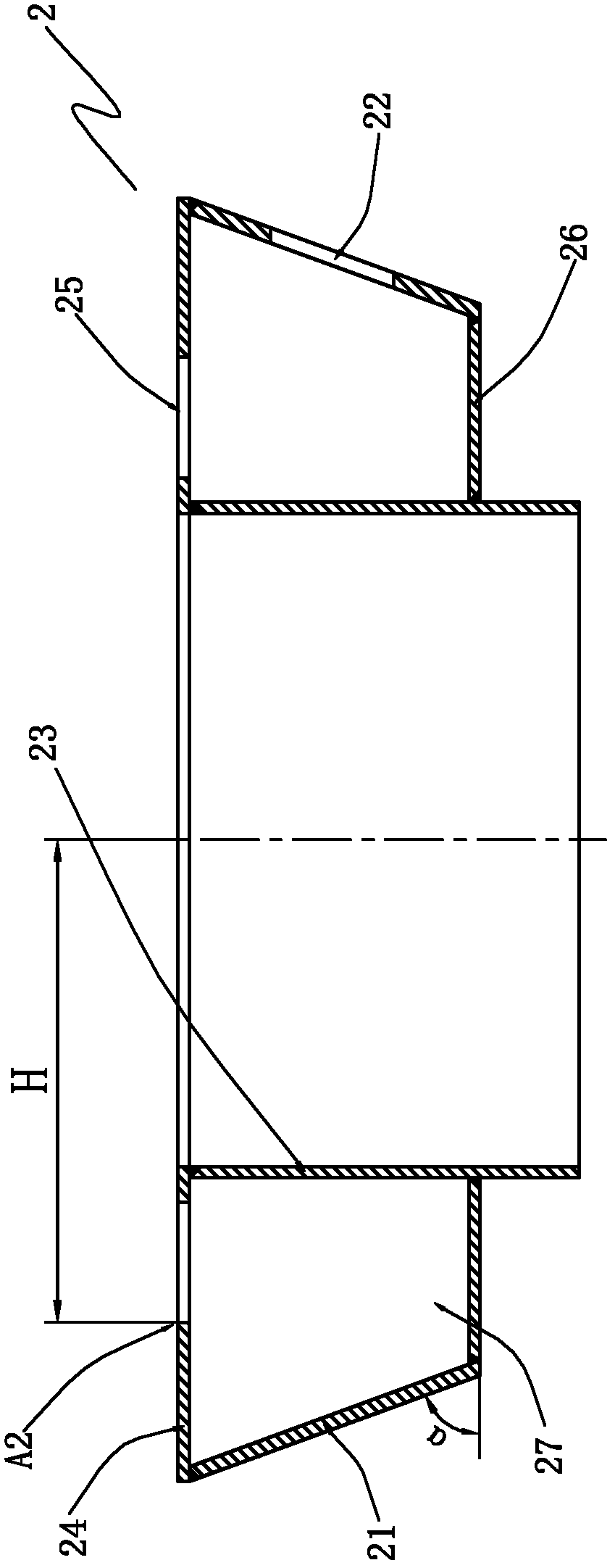

[0035]The present invention proposes a follow-up oxygen lance nitrogen sealing device, the follow-up oxygen lance nitrogen sealing device comprises a conical seat, a conical disc and a sealing disc, the conical disc and the sealing disc are sleeved on the oxygen lance above, wherein: the tapered seat has at least one inverted cone-shaped inner cone sealing surface, and more than one through hole is provided on the inner cone sealing surface, and the through hole communicates with the nitrogen supply pipe, and the tapered seat The lower part of the converter is fixedly connected with the oxygen lance inlet of the converter; the conical disk has an inverted conical outer conical sealing surface that matches the inner conical sealing surface of the conical seat, and is arranged inside the outer conical sealing surface 1. An oxygen lance channel whose diameter is greater than the outer diameter of the oxygen lance; an upper cover plate is provided between the outer cone sealing sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com