Novel overcoat lint machine

A technology for sweater and flannel, applied in the field of sweater flannel machine, can solve the problems of roughness and loose surface of three-thread flannel, and achieve the effect of small friction resistance, clear cloth surface and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

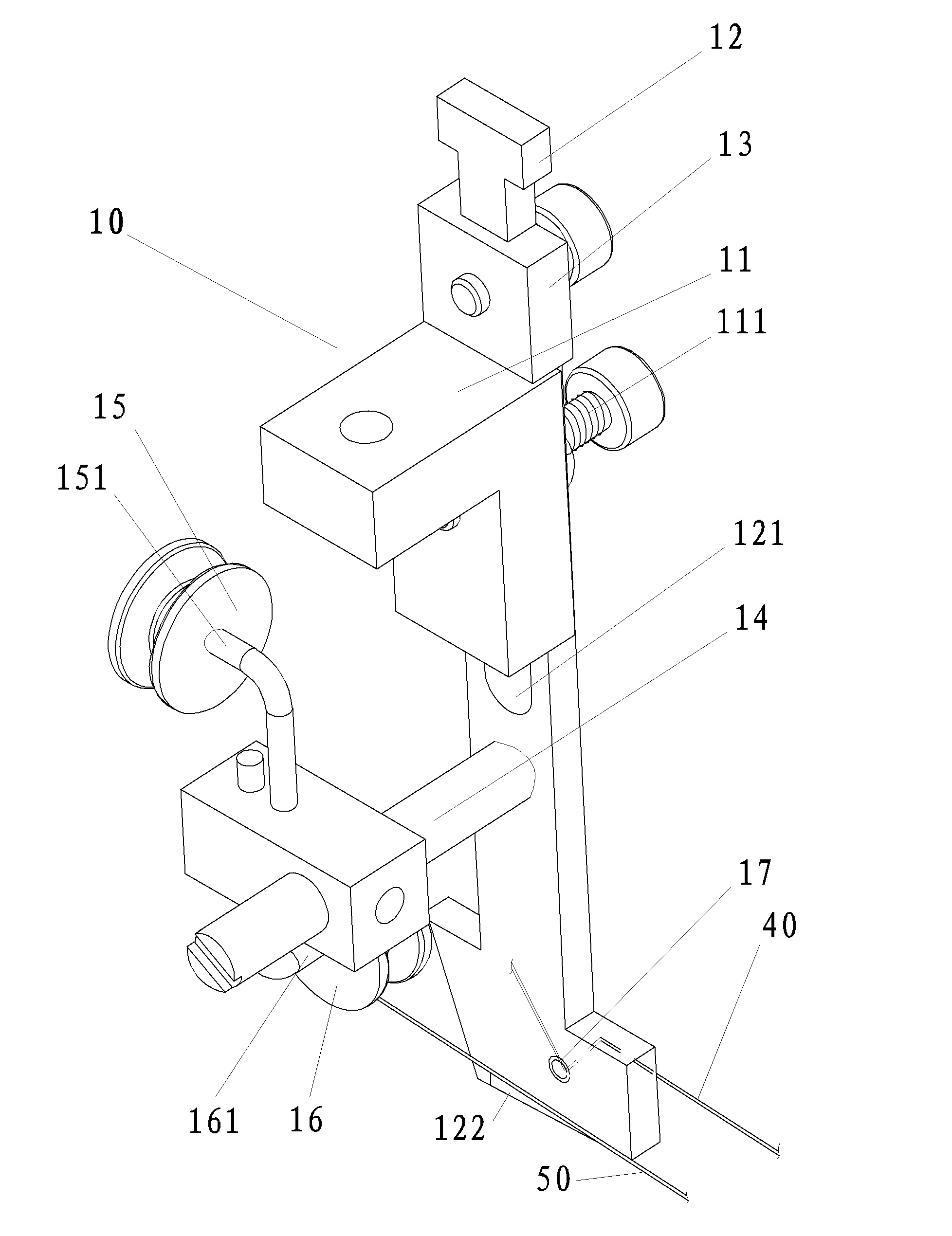

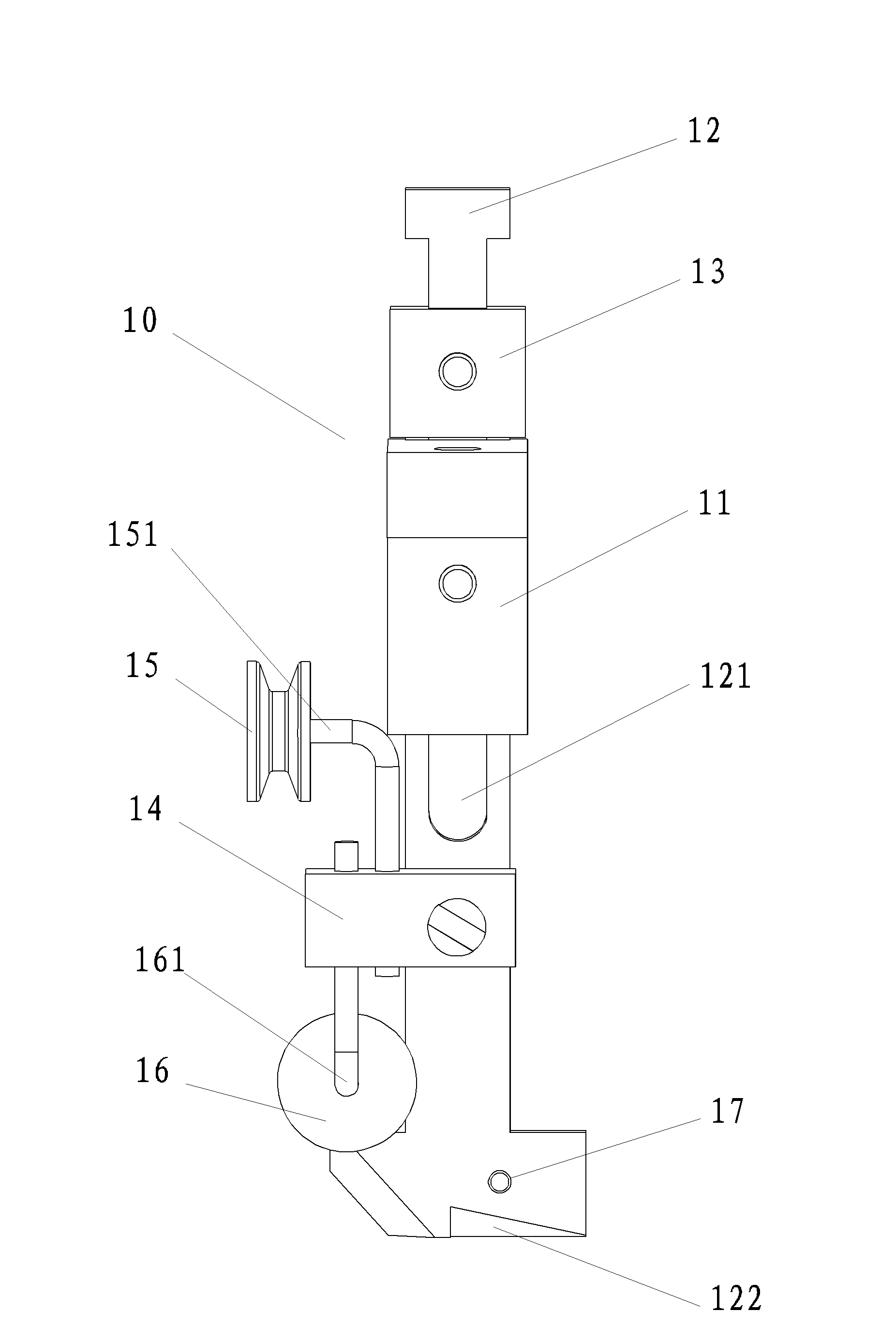

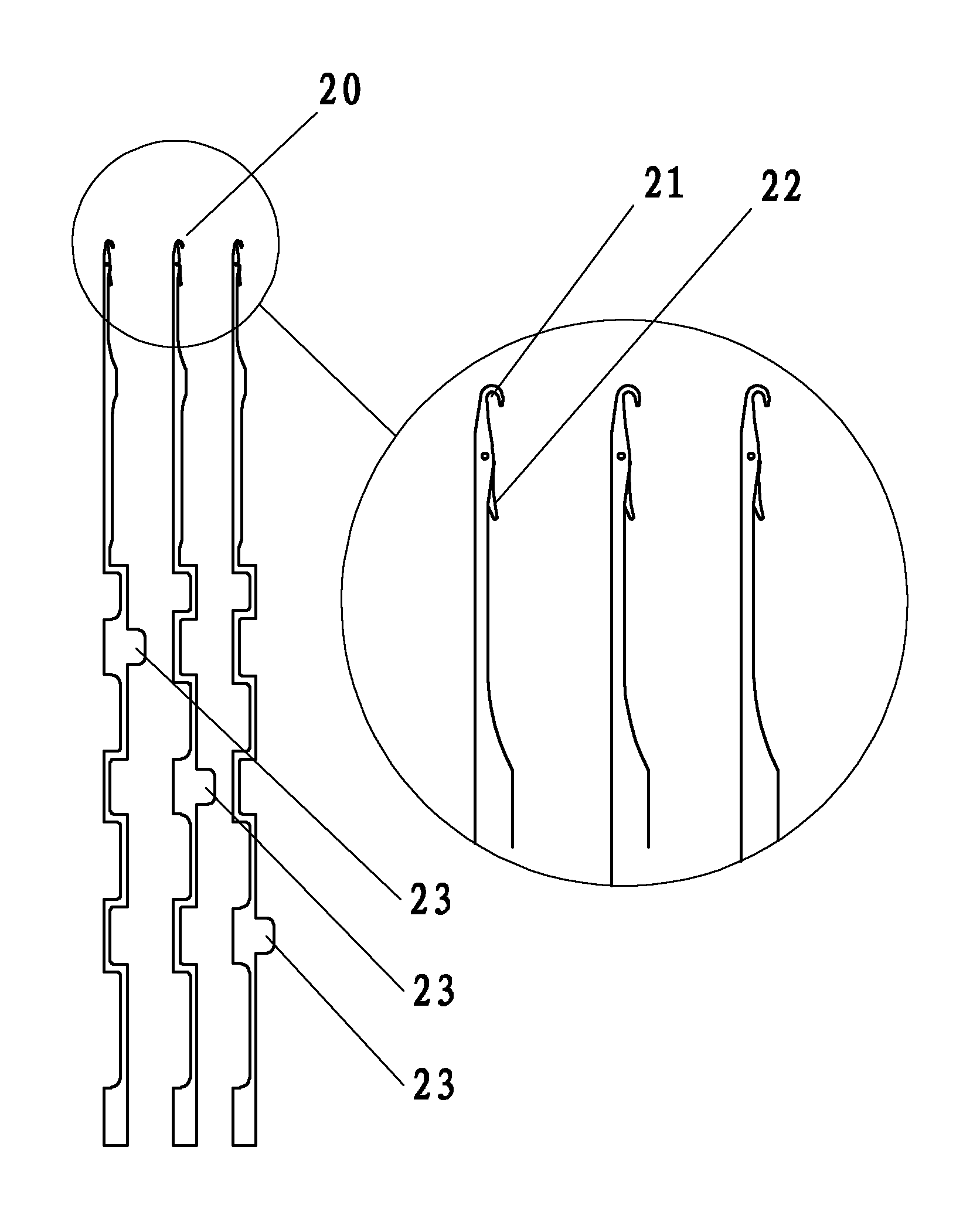

[0036] Such as Figure 1-5 As shown, the new sweater fleece machine of the present invention mainly includes a yarn feeding bar 10, knitting needles 20 and triangular blocks 30 that cooperate with each other.

[0037] The yarn feeding bar 10 comprises a fixed bar 11, a displacement bar 12, a positioning block 13, a wheel seat 14, an upper yarn guide wheel 15, a lower yarn guide wheel 16 and a yarn guide bushing 17. Among them, the fixed rod 11 and the displacement rod 12 of the yarn feeding rod 10, and the installation and cooperation of the fixed rod 11 on the sweater fleece machine are known technologies, and the application number can be referred to as 98201466. The utility model of "yarn bar". The upper part of the displacement rod 12 is respectively provided with a positioning slotted hole and a slotted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com