Anti-slip safe brake

A brake, anti-skid technology, applied in the direction of brake type, automatic brake, cleaning equipment, etc., can solve the problems of cumbersome operability, manual tightening, low reliability, etc., to achieve compact structure, solve braking problems, and novel structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

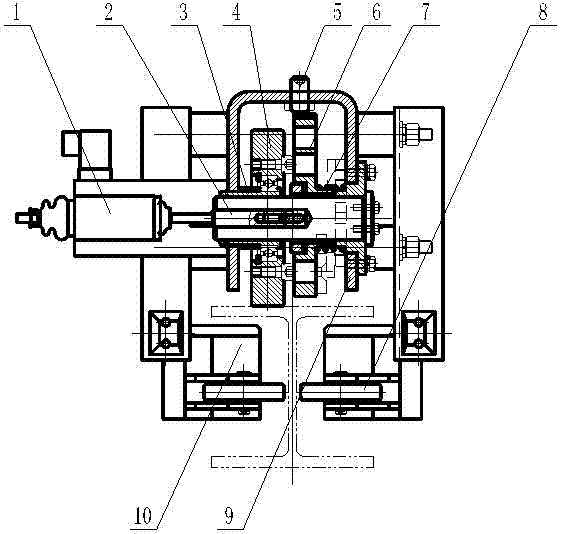

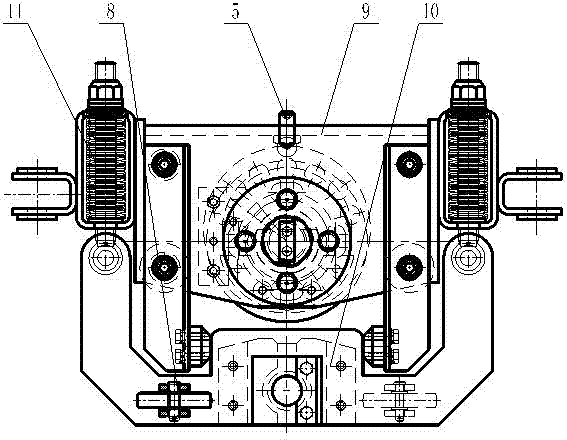

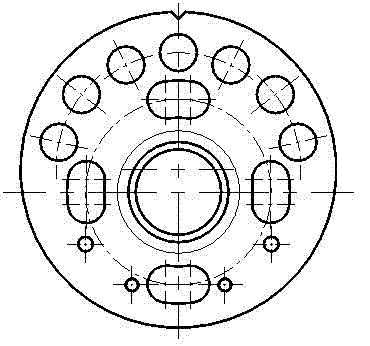

[0019] Such as figure 1 , 2 As shown, the power-off anti-skid brake of this embodiment includes: electric push rod 1, bearing shaft 2, positioning spacer 3, bearing wheel 4, positioning jack wire 5, eccentric wheel 6, thrust spring 7, horizontal guide wheel 8, frame body 9. Friction brake block 10, disc spring 11. The connection relationship is as follows: the electric push rod 1 is fixed on the frame body 9, the head of the electric push rod 1 withstands the bearing shaft 2, the positioning spacer 3 is set on the bearing shaft 2, the load wheel 4 is connected to the positioning spacer 3, and the positioning top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com