Momentum and energy absorption device shared by rubber and daub

A technology of energy absorbing device and actuating device, which is applied in the direction of fluid pressure actuating device, ammunition test, offensive equipment, etc. It can solve the problems of limited energy and difficulty in meeting the repeated use requirements of the test, and achieve easy cleaning and filling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

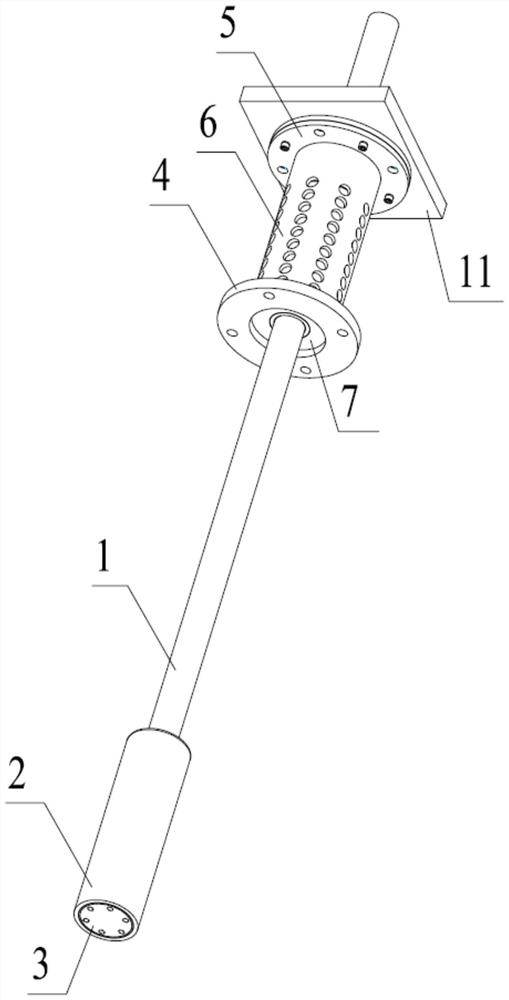

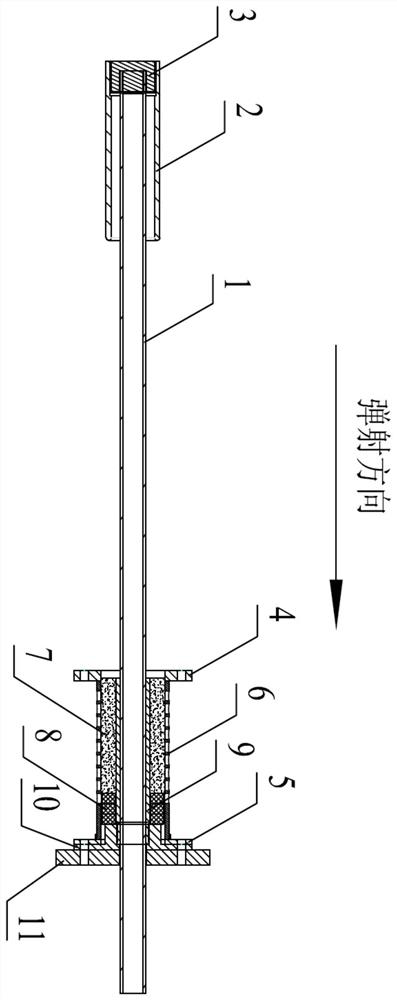

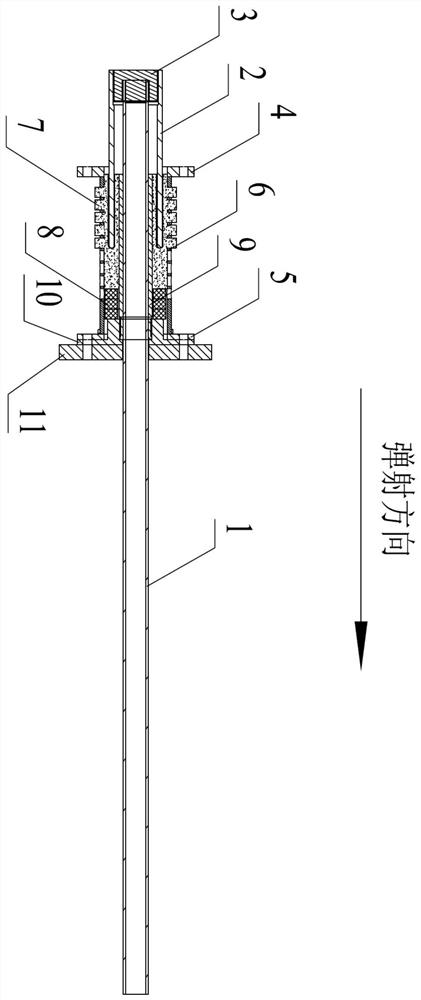

[0031] Such as figure 1 and figure 2 As shown, a momentum and energy absorbing device shared by rubber and cement includes: an actuating device, a guiding device and a buffering device; the actuating device impacts the buffering device through the guiding device, and the buffering device is provided with mastic 7 inside, and the buffering device passes through the mastic 7 The kinetic energy of the actuating device is absorbed, and the actuating device brakes by absorbing the kinetic energy through the cement 7; the side wall of the buffer device is provided with a through hole, and the cement 7 absorbs the kinetic energy and is discharged through the through hole; the actuating device includes: the inner rod 1 of the actuating device, the actuating device The outer rod 2 of the device and the adapter 3; the inner end of the outer rod 2 of the actuator is installed with the adapter 3, and the adapter 3 is fixedly connected to one end of the inner rod 1 of the actuator, and th...

Embodiment 2

[0033] Embodiment 2 is a preferred example of Embodiment 1.

[0034] Example 2

[0035] The present invention includes: an inner rod 1 of the actuating device, an outer rod 2 of the actuating device, an adapter 3, a front end plate of the outer sleeve 4, a rear end plate of the outer sleeve 5, an outer cylinder 6, cement 7, a rubber pad 8, and an inner cylinder 9. Adapter plate 10 and fixed plate 11; the inner rod 1 of the actuating device and the outer rod 2 of the actuating device are connected through the adapter 3 to form the actuating device; the outer cylinder 6 passes through the front end plate 4 of the outer sleeve and the rear end of the outer sleeve The plate 5 is fixed on the outer part, and there are several through holes on the surface of the outer cylinder 6; the inner cylinder 9 is nested in the outer cylinder 6 and fixed on the fixed plate 11 by the adapter plate 10 and the rear end plate 5 of the outer sleeve; Three ring-shaped rubber pads 8 are placed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com