Hydro-electric braking system

A technology of electro-hydraulic brakes and brake master cylinders, which is applied in the direction of brakes, brake transmission devices, vehicle components, etc., can solve the problem of braking without serving pure electric vehicles, etc., and achieve small volume, small volume requirements, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing by specific embodiment:

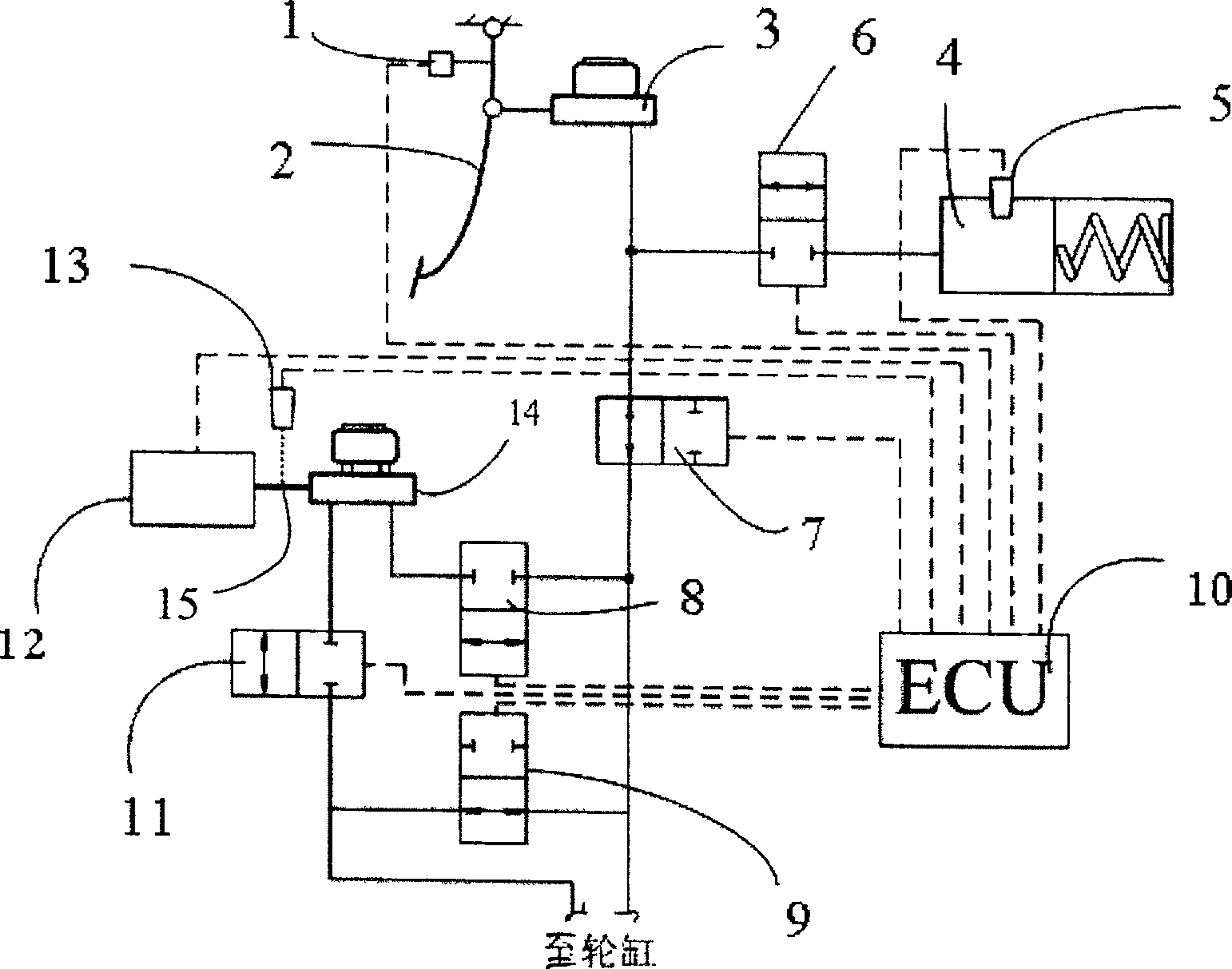

[0018] An electro-hydraulic brake system for a pure electric vehicle includes three parts, namely a brake simulation part, a brake execution part and an ECU control part. Such as figure 1 Shown:

[0019] The brake simulation part includes a normally open contact switch 1 , a brake pedal 2 , a first brake master cylinder 3 , a brake simulator 4 , a hydraulic pressure sensor 5 and a normally closed solenoid valve 6 . The brake pedal 2 withstands the electric shock switch 1 and is connected with the first brake master cylinder 3. The brake simulator 4 is equipped with a hydraulic pressure sensor 5, and the first normally closed solenoid valve 6 is arranged between the first brake master cylinder 3 and the first brake master cylinder 3. Between brake simulator 4.

[0020] The brake execution part includes a first normally open solenoid valve 7, a second n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com