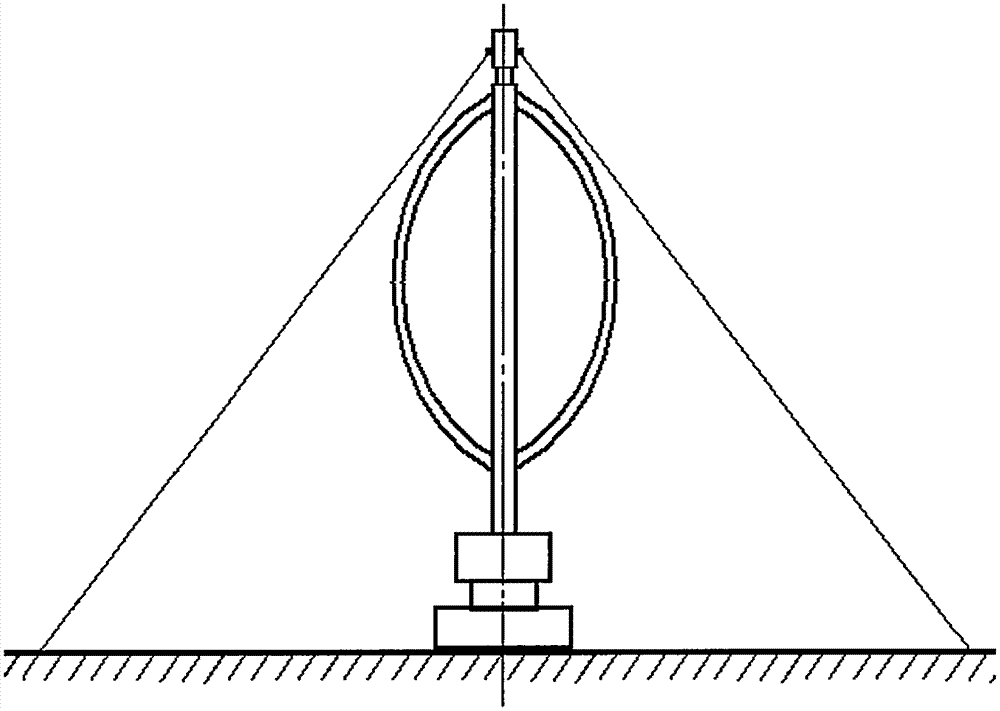

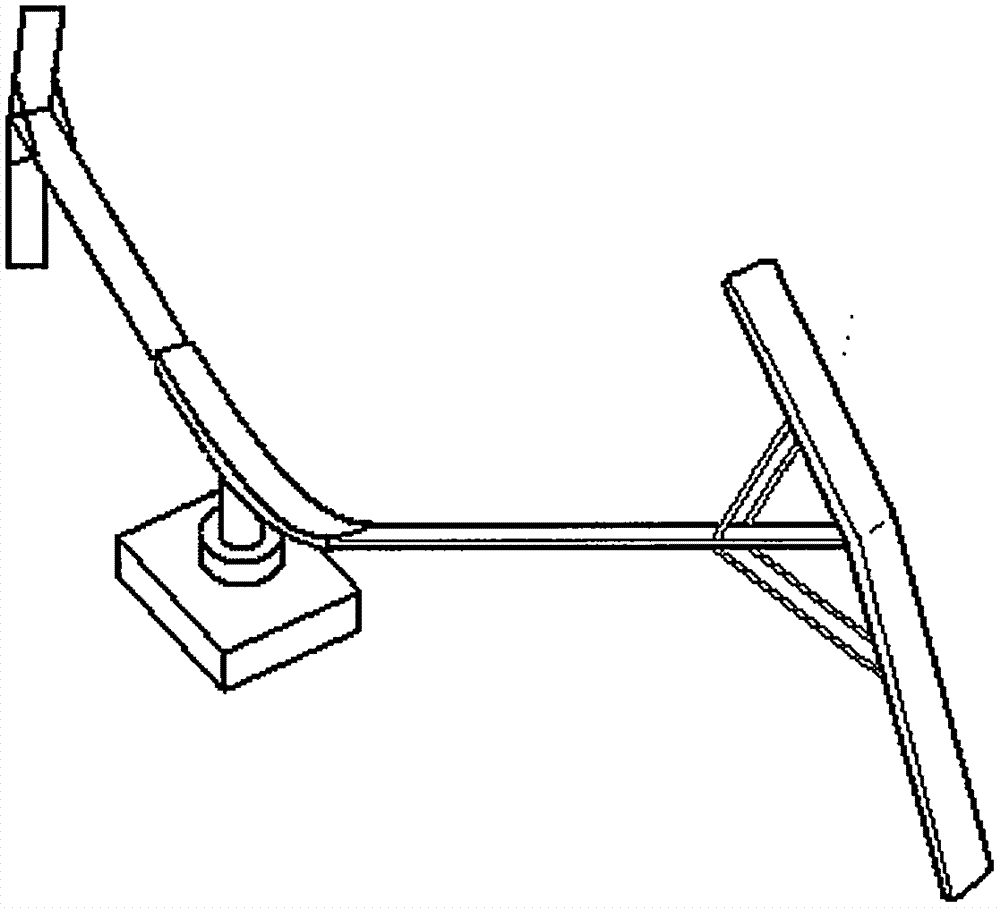

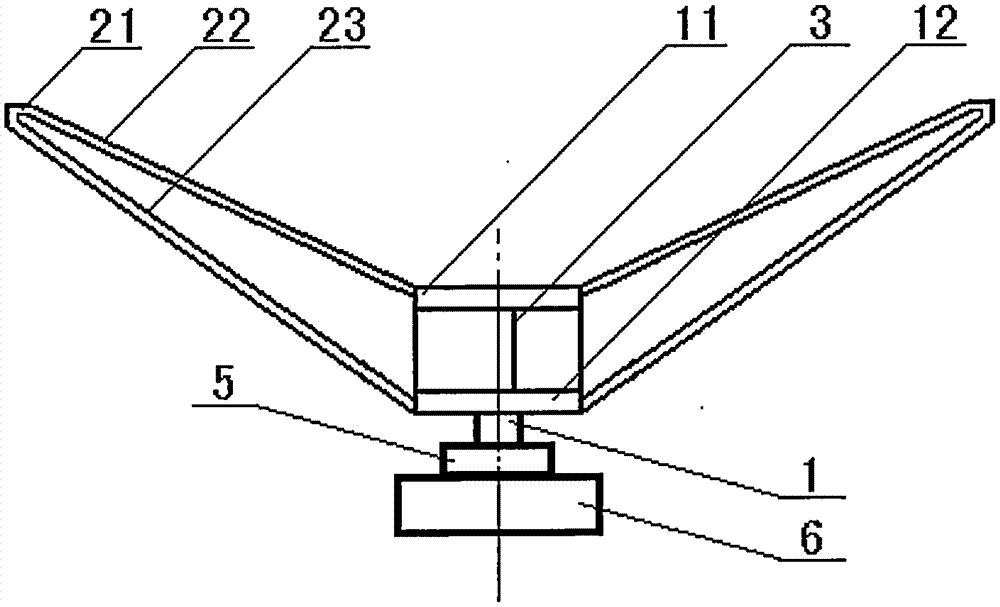

Strong-blade magnetic suspension large vertical axis wind power system

A wind power system, vertical axis technology, applied to wind turbines, wind turbine combinations, wind turbines and other directions at right angles to the wind direction, can solve the problems of noise that hinder the normal operation of the turbine, easy vibration, large deflection of the blade arm, etc. The effect of high failure rate and high maintenance cost, increased rigidity, structural strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The current large-scale mass-produced commercial wind turbines are mainly 2-3MW horizontal axis turbines. Horizontal axis wind turbines usually use thin three-needle epoxy resin or carbon fiber-reinforced airfoil blades. The root end of the blade is fixed on the hub and connected to the main shaft through the hub. Under the action of the wind, the main shaft is driven to rotate to output mechanical energy, and then through the generator And the converter converts mechanical energy into constant frequency and constant voltage electric energy and inputs it into the grid. The three-pin blade adopts the single-end fixed form of the cantilever beam structure. Therefore, the blade has a large structural stress, is easily deformed, has a low structural strength, and is easily damaged by the wind. Therefore, frequent blade breakage accidents occur in strong winds. This is a horizontal axis fan. The most fatal structural weakness. Therefore, when the power is increased to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com