Multifunctional aluminum alloy hollow structure wallboard and forming preparation method thereof

A hollow structure, aluminum alloy technology, applied in the fuselage bulkhead, space navigation equipment, space navigation equipment and other directions, can solve the problems of high temperature resistant material ratio, severe stress state, low density, etc., to achieve high structural strength The effect of rigidity, integration of structure and function, and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

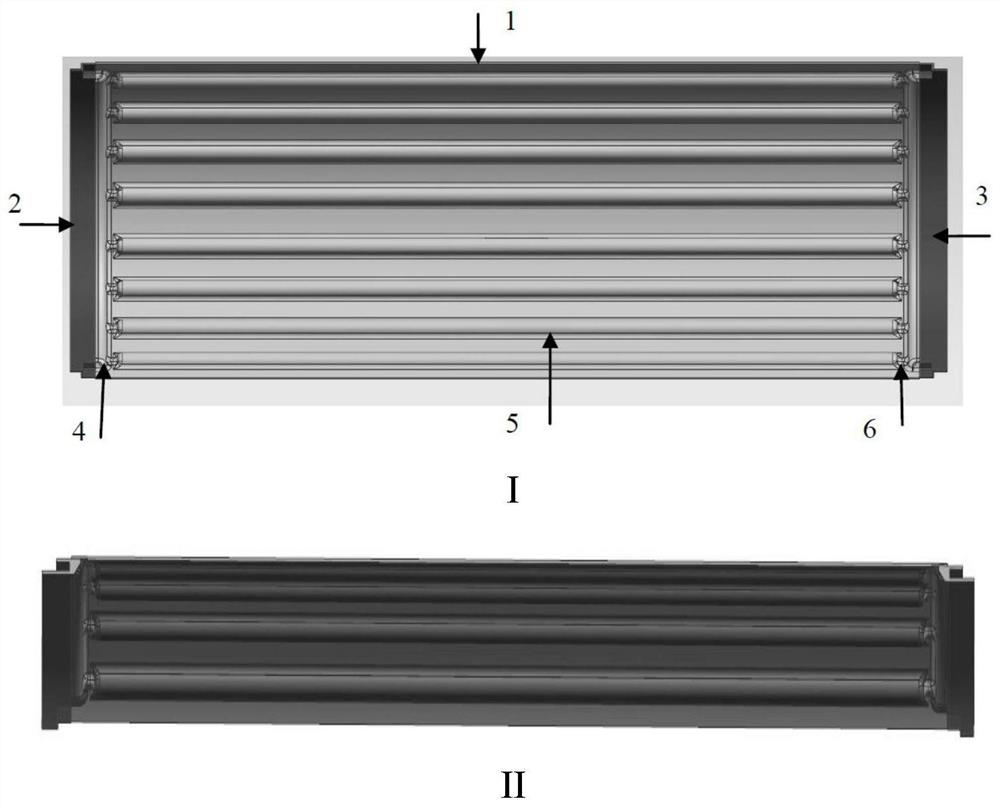

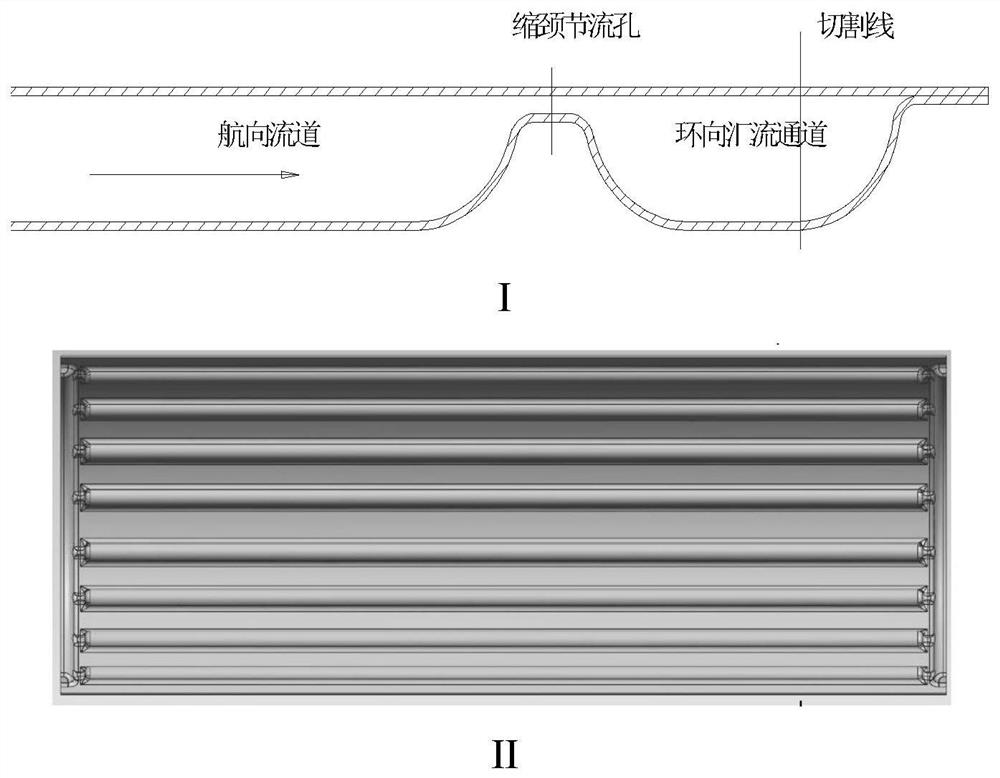

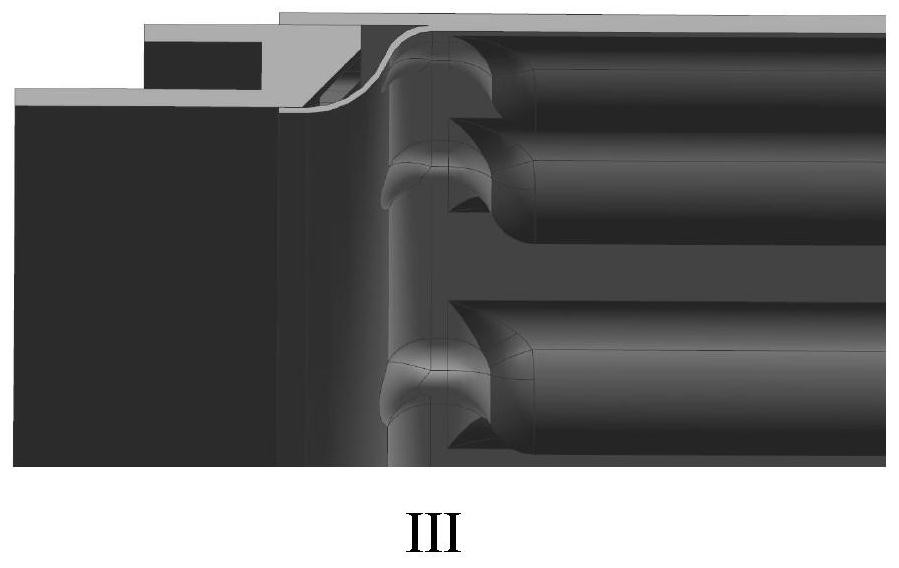

[0046] refer to Figure 1 to Figure 5 As shown, the process of forming and preparing the multifunctional aluminum alloy hollow structure wall panel of this embodiment is as follows:

[0047] Step 1: Hollow panel forming

[0048] In this embodiment, the hollow structure wall panel adopts 5083 plate, and the state of the plate is O state, wherein the flow channel layer of the inner layer is selected as a plate with a thickness of 1mm, the panel of the outer layer is selected as a plate with a thickness of 2mm, and the diameter of the necking orifice is designed to be 5mm. The necking orifice can be realized through the mold; the confluence ring frame is made of 5A06 thick plate, and the state is O state.

[0049] A1.1. The forming of the hollow structure wall panel adopts the combined process of electron beam penetration welding / inflatable forming. After compacting with tooling in the flat state, penetration welding is carried out on the inner 1mm plate. The welding process par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com