An all-metal packing case for an engine

A technology for engines and packaging boxes, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of unsuitable heavy-duty engine packaging, lack of moisture-proof and anti-corrosion capabilities, and low structural strength of fixed lock pins, so as to meet the requirements of storage operations requirements, isolation from the external environment, good performance, and improved maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

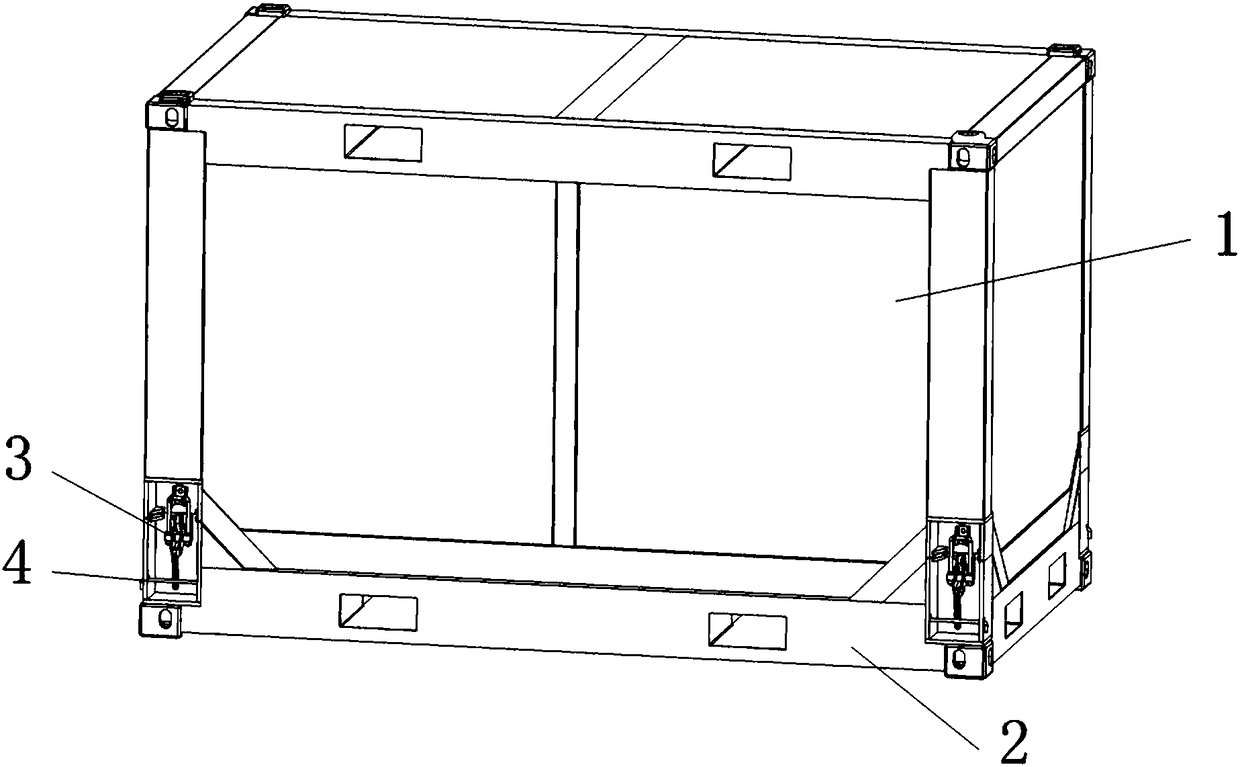

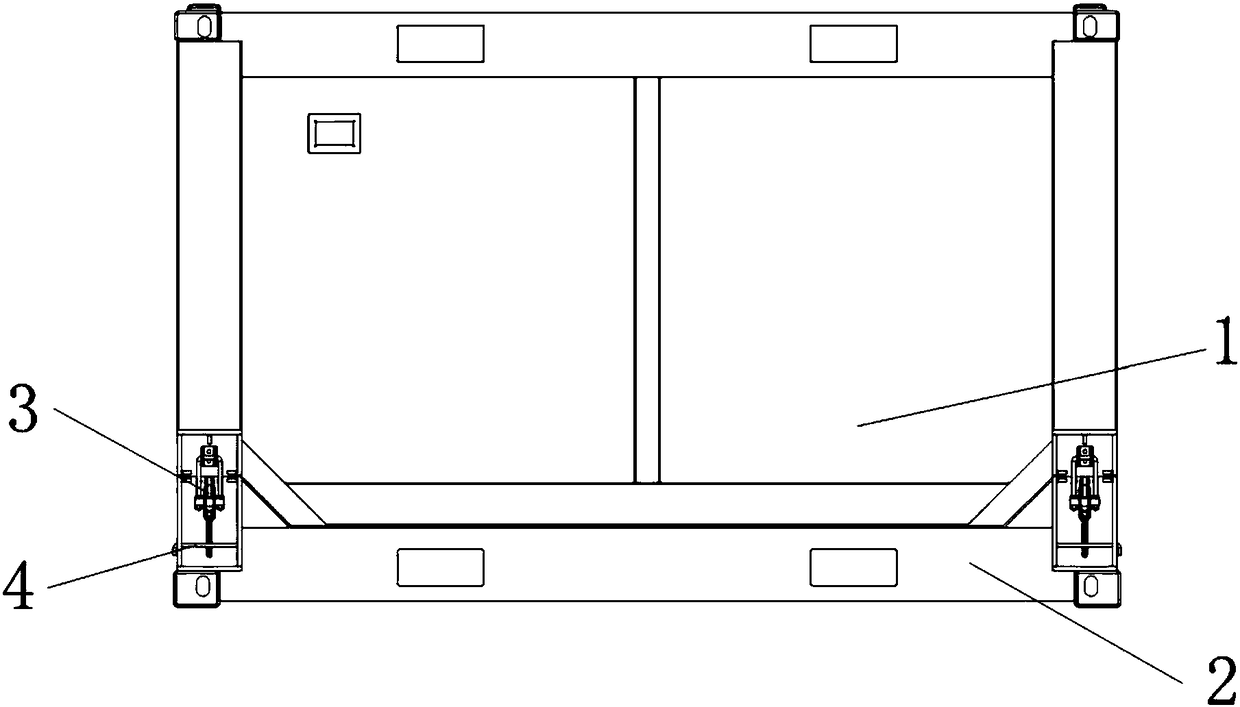

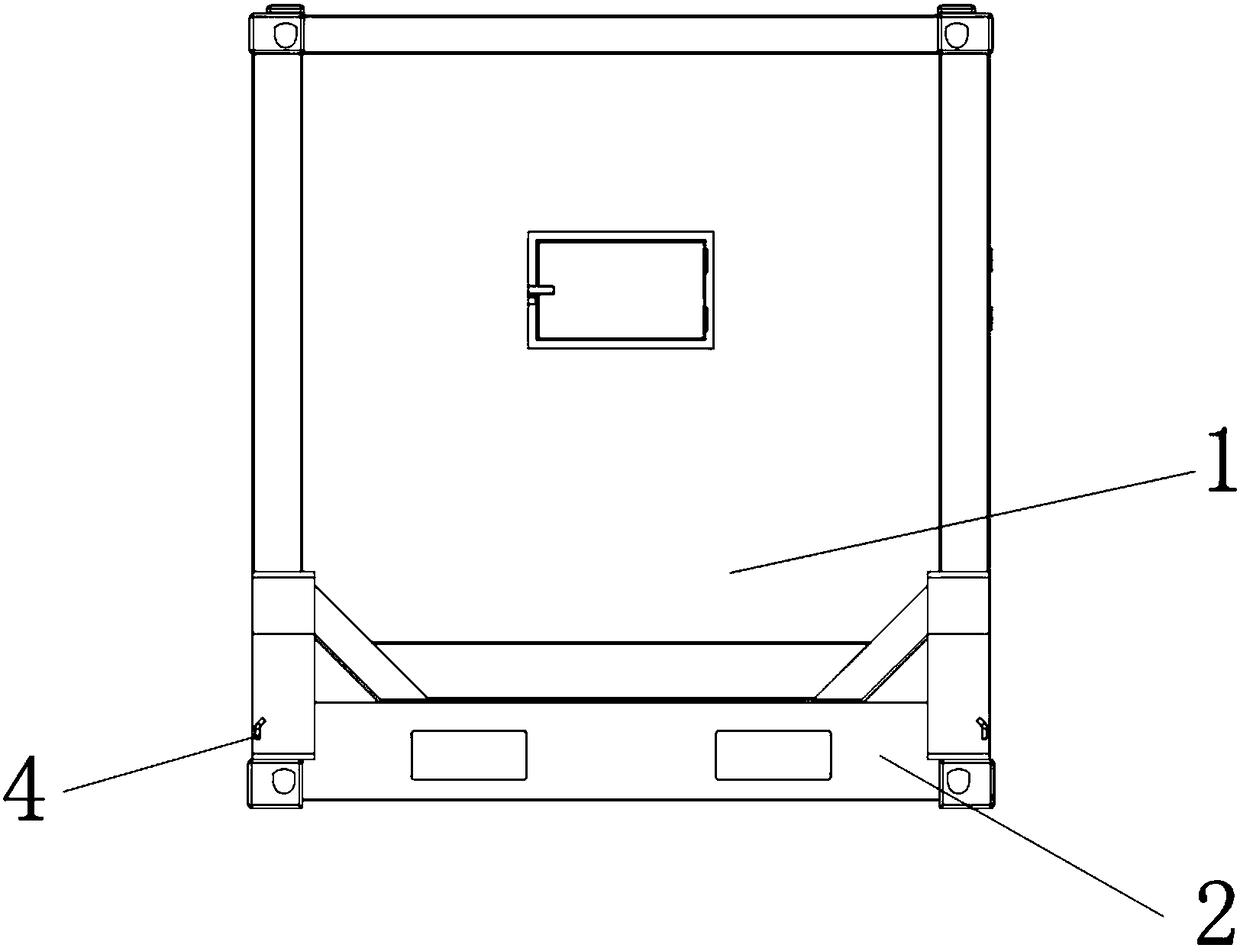

[0031] as attached figure 1 As shown, an all-metal packaging box for an engine of the present invention includes a top cover 1 , a base 2 , four sealing calipers 3 , stop pins 4 , four sets of supporting frames 5 and four pressing bar calipers 6 .

[0032]The top cover 1 includes four upright posts 101, a square upper frame 102, two top cover forklift square pipes 103, four upper mounting seats 104 for sealing clamps, eight top cover guide blocks 105, two lower longitudinal Beam 106, two lower beams 107, top cover plate 108, four upper corner pieces 109 and four support frame clamp baffles 110, radio frequency tags 111 and observation windows 112, the upper ends of the four columns 101 are vertical respectively Installed on the four corners of the square upper frame 102, the lower ends of the four columns 101 are respectively fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com