Multicore-fiber-based optical motor and micropump

A multi-core optical fiber and motor technology, applied in the field of micro-drive devices, can solve the problems of high cost, bulky laser optical tweezers, and difficult to move, and achieve the effects of cheap price, saving operating space, and convenient operating position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in more detail below in conjunction with accompanying drawing example:

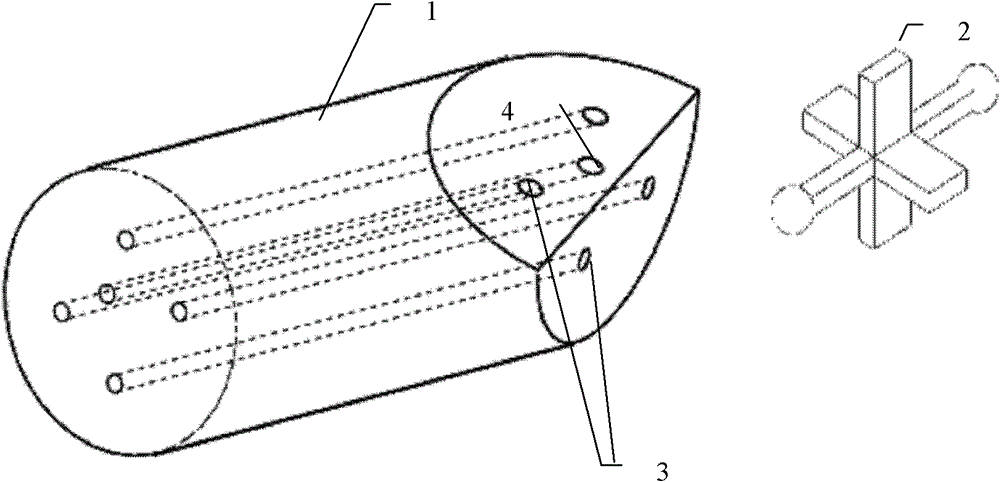

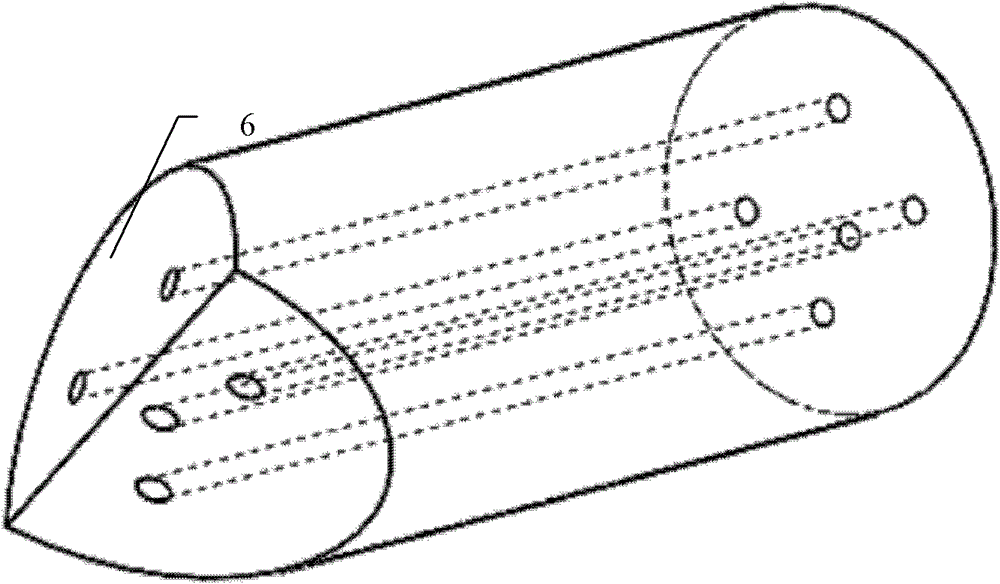

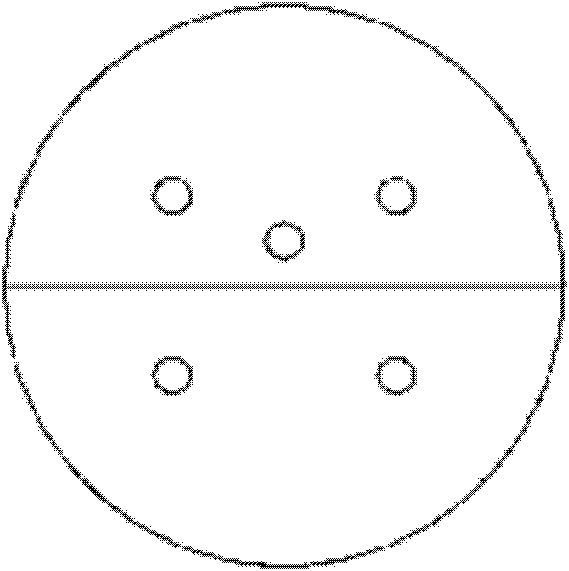

[0030] to combine figure 1 , the optical motor based on the multi-core optical fiber of the present invention includes a multi-core optical fiber 1 and a micro-rotor 2 with a wedge-shaped front end; Figure 6-8 , the micro-rotor includes a sphere, a rotating shaft and wings, 3-8 wings are arranged on the rotating shaft, and two spheres are installed on both ends of the rotating shaft to form a micro-rotor with a symmetrical structure; the multi-core optical fiber with a wedge-shaped front end includes a The double-optical tweezers capture the sphere of the micro-rotor and act as two pairs of bilaterally symmetrical fixed-axis cores 3 , which also include a drive core 4 that emits outgoing light to drive the wings of the micro-rotor. The described front end is a wedge-shaped multi-core optical fiber. The front end of the multi-core optical fiber is precisely proce...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap