Fully-automatic high-speed bag making machine

A bag making machine, fully automatic technology, applied in the direction of envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc., to achieve the effects of avoiding damage, stable film conveying, convenient feeding and blade replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

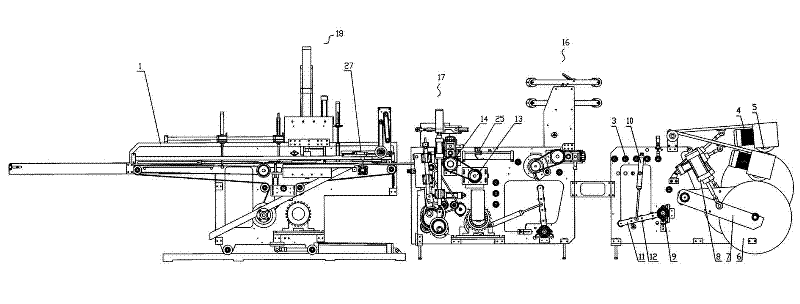

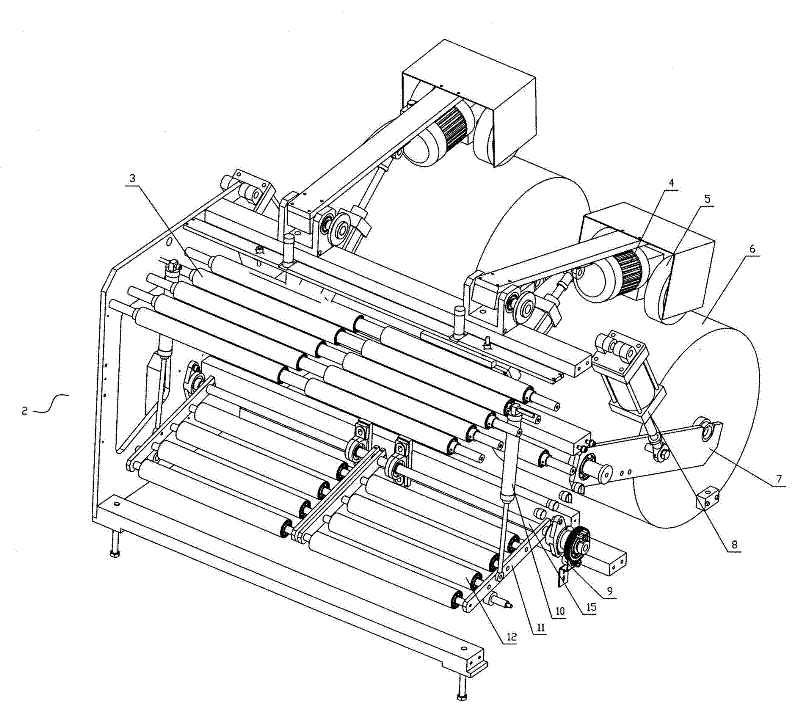

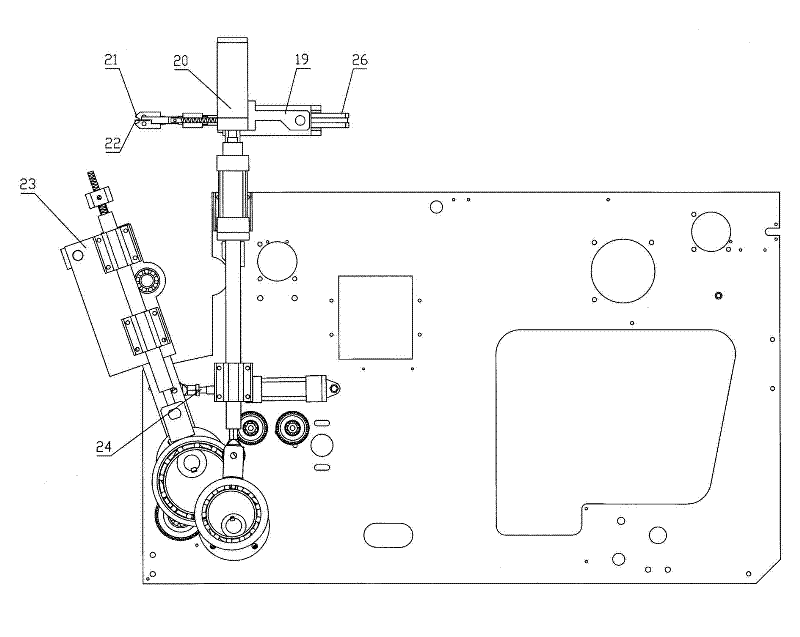

[0012] With reference to the accompanying drawings, this kind of fully automatic high-speed bag making machine includes a frame 1 and a transmission device, and the frame is provided with a feeding device 16, a cutting and sealing device 17 and a punching device 18 in sequence, and the feeding device 16 includes There is a motor 4, a material rack 7 and a film conveying mechanism 2, the material rack 7 is movably installed on the frame 1, and rotates on the frame through the feeding cylinder 8, and the output shaft of the motor 4 is connected to a feeding roller 5. The feeding roller 5 is in contact with the film material roll 6 on the material shelf during working conditions. The film conveying mechanism 2 includes a guide roller 3, a floating assembly, a linear potentiometer 9, a transmission motor 13 and a motor connected to the transmission motor. Conveying roller 14, described floating assembly includes support 11 and floating roller 12 and floating roller shaft 15 install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com