Transmission

A technology of transmission and synchronizer, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc. It can solve the problems of increasing the cost of the automatic transmission operating system, power interruption, and shortening the life of the clutch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

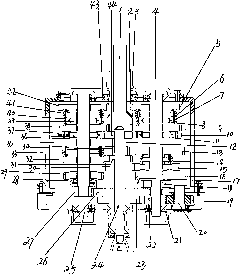

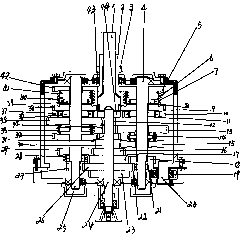

[0009] refer to figure 1 , the outer shaft 2 is fixed by the bearing 43 and extends out of the housing 3, the inner shaft 1 is fixed by the bearing and extends out of the outer shaft 2, the outer shaft 2 is connected with the protruding part of the inner shaft 1, and the groove end of the inner shaft 1 It is connected with the protruding ends of the inner two shafts 24, and the rear ends of the inner two shafts 24 are connected and fixed with the housing 3 through bearings. One-way clutch 36,39 is housed on, and brake 37 is housed outside one-way clutch 36, and synchronizer 40 is housed outside one-way clutch 39, and one, three, five and seven gear driving wheels 27,29,32,35 are also housed on the odd shaft 25 , Constant meshing gears 38,42, synchronizers 28,33,41. One-way clutch 8,11 is housed on the even shaft 4, and brake 10 is housed outside the one-way clutch 11, and synchronizer 7 is housed outside the one-way clutch 8, and reverse gear, second, forty-six gear driving w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com