Gear-driven opposed piston engine

A piston engine, gear transmission technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems of large occupied space, complex structure of crank connecting rod mechanism, high manufacturing cost, improve compactness, simple structure, and realize automatic steering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

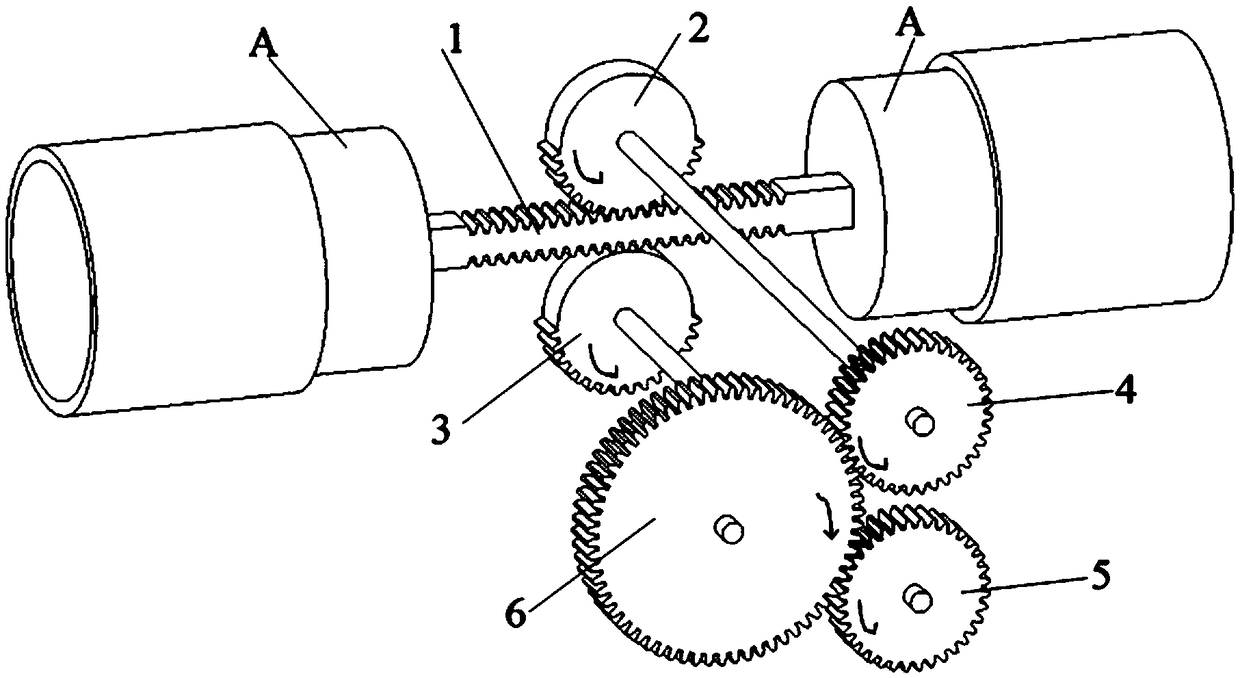

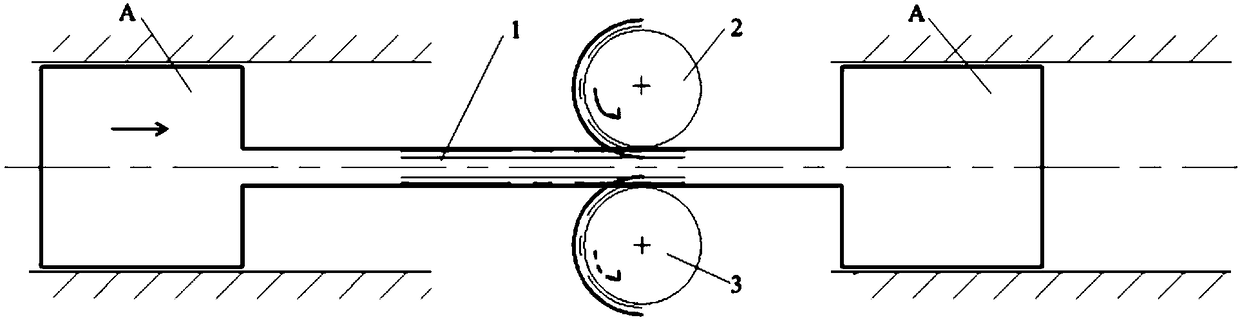

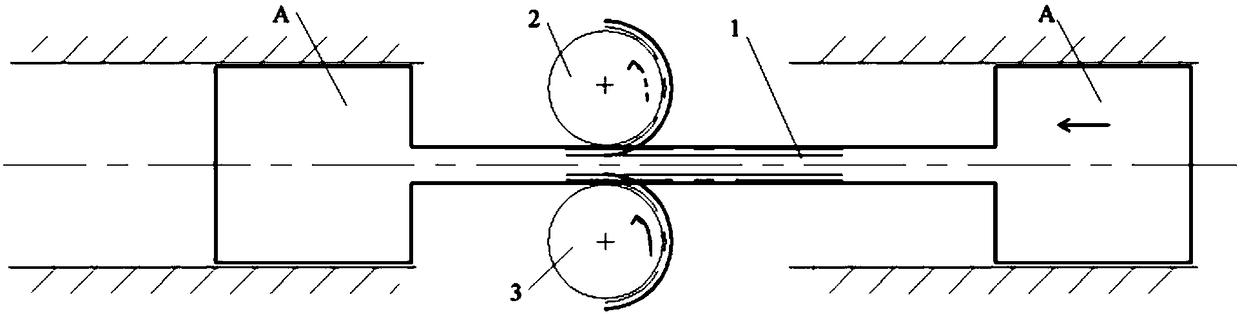

[0019] A geared opposed-piston engine such as figure 1 As shown, it includes a pair of opposed pistons, rack 1, first incomplete gear 2, first coaxial gear 4, second incomplete gear 3, second coaxial gear 5, output gear 6,

[0020] The two opposing pistons are fixedly connected by a rack 1, and transmission teeth are symmetrically distributed on two opposite surfaces of the rack 1, and the transmission teeth on both sides are connected with the first incomplete gear 2 and the second incomplete gear 3 respectively. meshing; the first incomplete gear 2 meshes with the output gear 6 through the first coaxial gear 4 connected thereto, and the second incomplete gear 3 meshes with the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com