Connecting rod of two-stroke diesel engine with opposed pistons

A technology of opposed pistons and two strokes, which is applied in the direction of valve devices, mechanical equipment, engine components, etc., can solve problems such as unsatisfactory connecting rods, achieve the effects of simplifying the connecting rod structure, reducing the reciprocating inertial force, and strengthening the connection stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

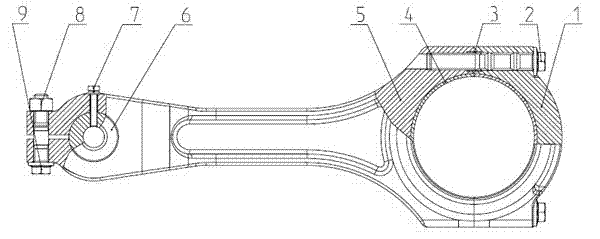

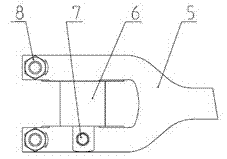

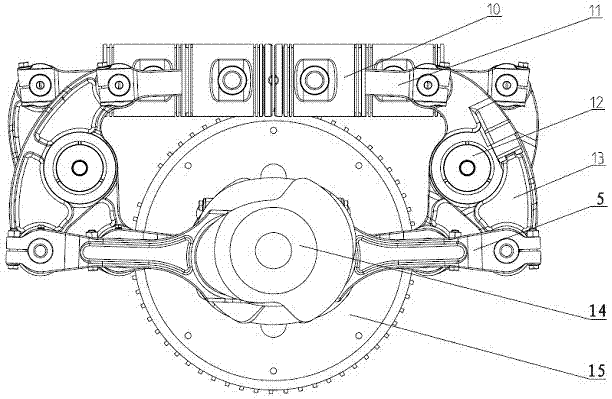

[0013] Such as figure 1 , 2 As shown, a connecting rod of a two-stroke diesel engine with opposed pistons, which includes: connecting rod cover 1, connecting rod bolt 2, positioning sleeve 3, bearing bush 4, connecting rod 5, rocker arm lower pin 6, bolt assembly 7, nut 8. Bolt 9; one end of the connecting rod 5 is the small head side, and the other end is the big head side. The small head side is set as a fork-shaped structure with a U-shaped middle opening, and a process protrusion is arranged inside the fork-shaped structure. At the same time, the rocker arm lower pin 6 is set in its fork-shaped structure, the rocker arm 13 is installed in the U-shaped structure through the rocker arm lower pin 6, and the outer side of the rocker arm lower pin 6 has a 3mm through groove, which is convenient for rocking The lower pin 6 of the arm is loaded and pressed; the upper and lower parts of the through groove are provided with through holes for installing the bolt 9 and the nut 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com