Tool for making transformer coil

A technology of transformer coils and transformers, applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problem that multiple divisions and windings cannot be performed, and transformer windings, divisions, and pressure cannot be performed at one time. Continuous completion, low production efficiency and other problems, to achieve the effect of saving man-hours, high precision, and reducing line division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

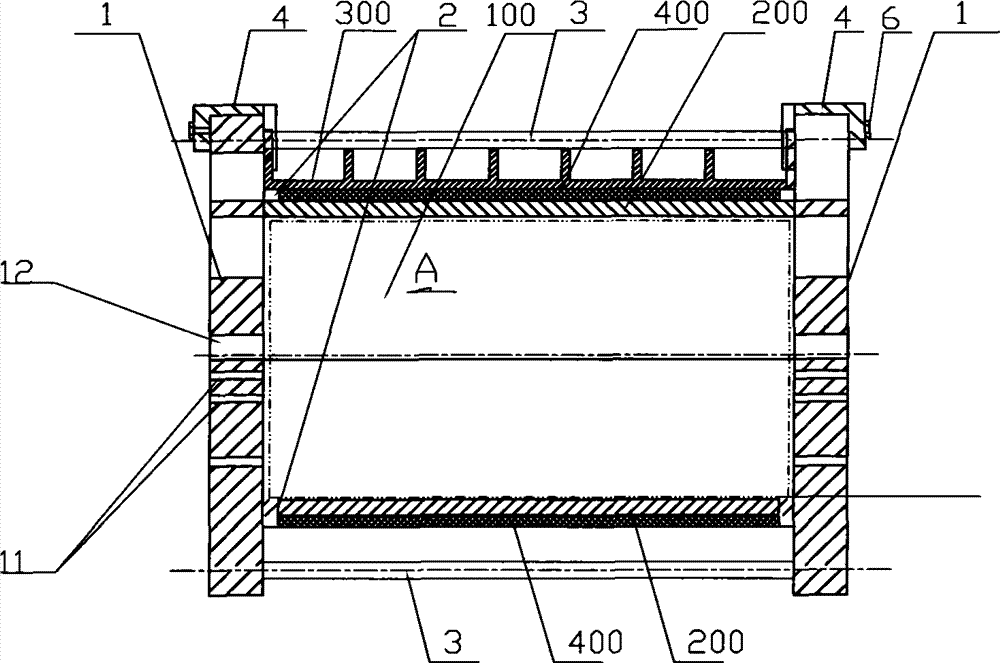

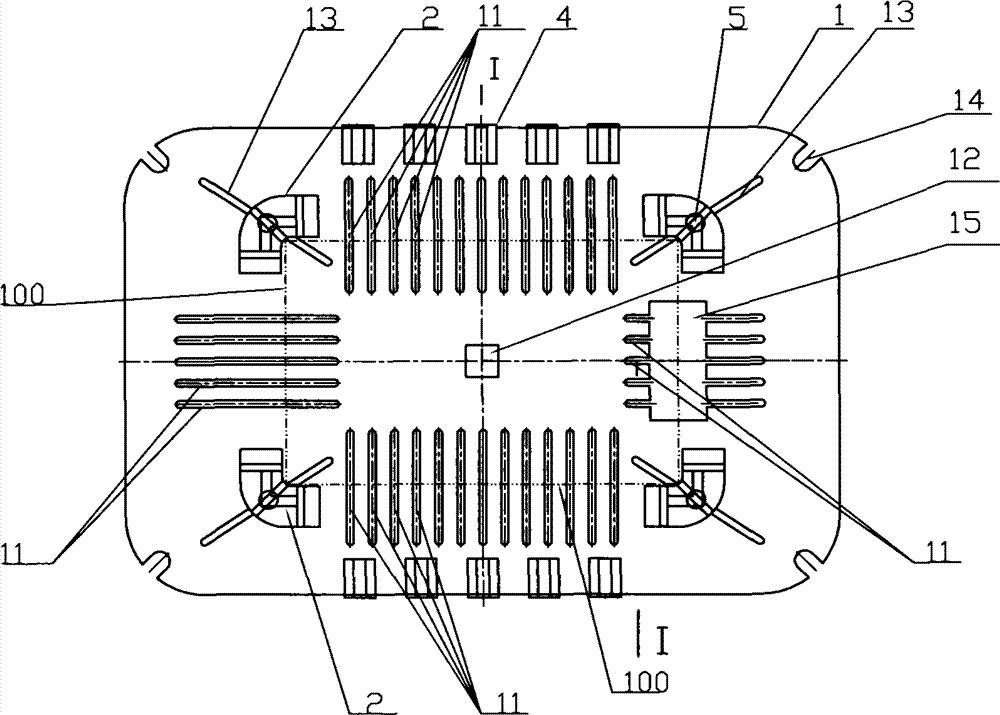

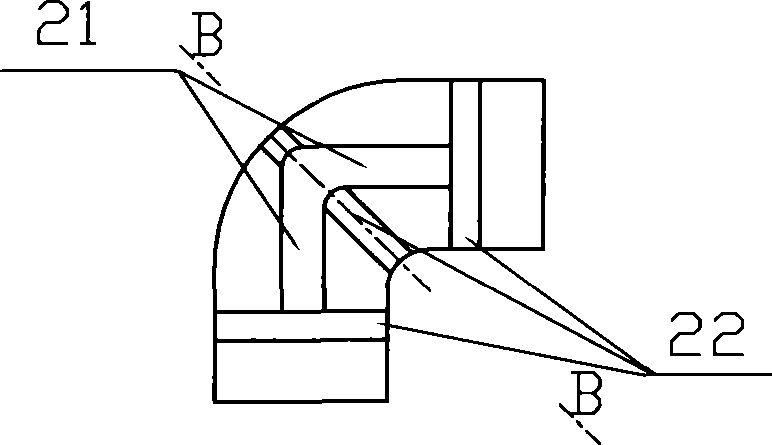

[0039] see figure 1 , figure 2 , figure 1 yes figure 2 I-I sectional view, figure 2 yes figure 1 The A-direction view of the present invention will be described in detail below in conjunction with specific embodiments. The tooling for transformer coil production according to the present invention includes two spaced and oppositely arranged baffles 1. In this embodiment, the baffles 1 are rectangular in shape. For clamping the rectangular insulating cylinder 100, there are long slots 11 for placing the stays 200 on the plate width of the baffle plate 1. The long slots 11 are arranged at intervals corresponding to the positions outside the transformer insulating tube. The long slots 11 The struts 200 can be arranged very densely, and the struts 200 can be inserted into the long slots 11 with a suitable spacing at intervals as required. The central position of the pressure baffle 1 is provided with a square centering hole 12 for installing the insulating cylinder 100 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com