Plug-in connector

A plug connector, wire connection technology, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problem of weakening elastic properties of contact rail elements, achieve good spring contact and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

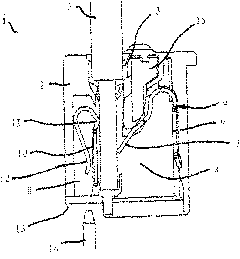

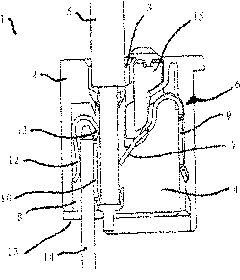

[0069] figure 1 A sectional view of a first embodiment of the plug-in connector 1 is shown in cross section. The plug-in connector 1 has a housing 2 made of insulating material, in which a wire socket 3 leading to a wire connection chamber 4 is arranged. The electrical wire 5 can be inserted into the wire connection cavity 4 through the wire insertion hole 3 .

[0070] Mounted in the conductor connection chamber 4 is a clamping spring element 6 , whose clamping leg 7 presses against the electrical conductor 5 and exerts a force in the direction of the contact pin receiving opening 8 . The clamping spring element 6 is fastened in the insulating material housing 2 via fastening legs 9 .

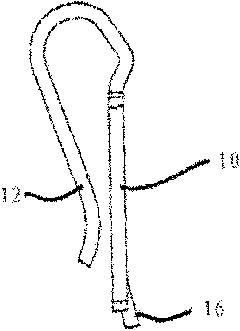

[0071] A busbar element 10 is mounted between the contact pin receiving opening 8 and the electrical line 5 or the line connection space 4 . The busbar element 10 has a curvature 11 protruding in the direction of the conductor connection chamber 4 in order to provide a defined, reduced conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com