Method for preparing a food liquid contained in a capsule by centrifugation and system adapted for such method

A liquid food and preparation system technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of controlling pressure and not being able to change pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

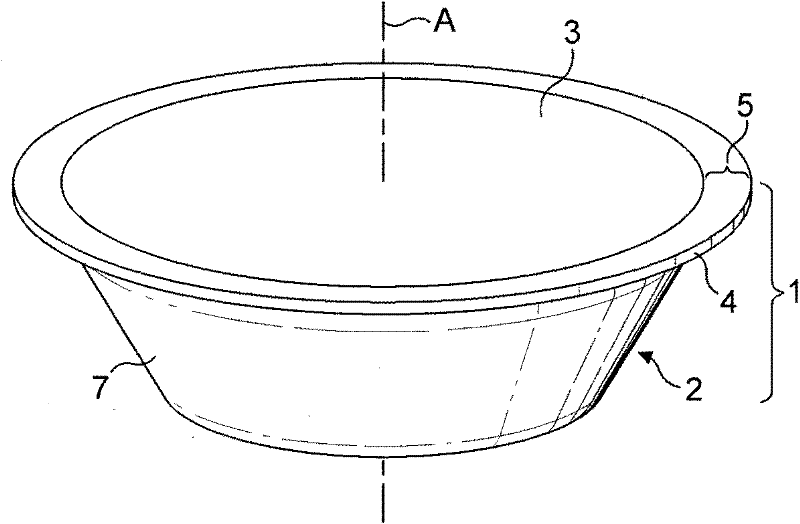

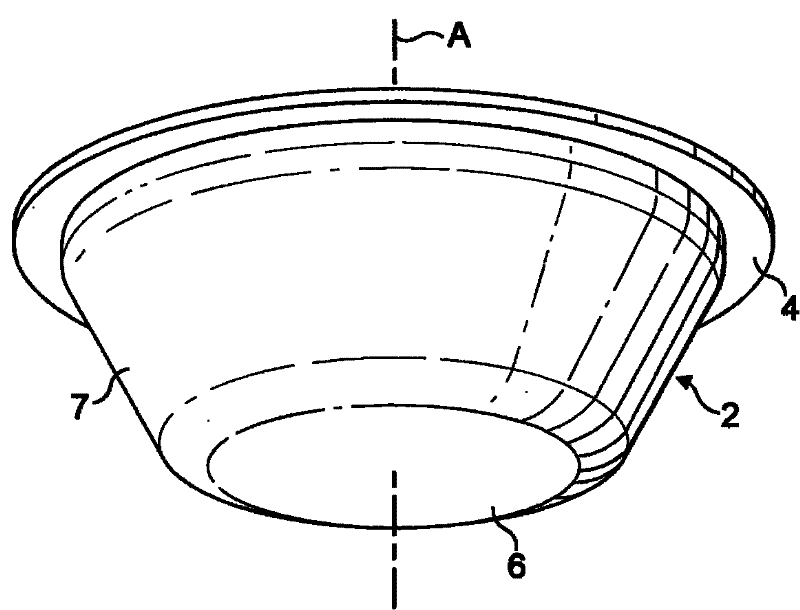

[0066] Such as figure 1 and figure 2 As shown, the preferred single-use capsule 1 of the invention comprises a disc-shaped body 2 on which a sealing foil or membrane 3 is sealed. The sealing foil 3 is sealed on the periphery 4 of the body in a sealing ring 5 . The peripheral edge 4 may extend outwards to form a small annular seal of about 2-5 mm. The disc-shaped body comprises a bottom wall 6 and a side wall 7 which preferably widens in the direction of the large open end of the body opposite the bottom wall. The disc-shaped body is preferably rigid or semi-rigid. The disc-shaped body can be formed of food-grade plastic (such as polypropylene) or aluminum alloy or a composite of plastic and aluminum alloy with a gas barrier layer (such as EVOH, etc.). The sealing foil 3 can be made of a thinner material, eg a plastic laminate which also includes a shielding layer or an aluminum alloy or a combination of plastic and aluminum alloy. The sealing wall typically has a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com