Preparation method of magnetic fluorescence dual-function silicon oxide hollow microspheres

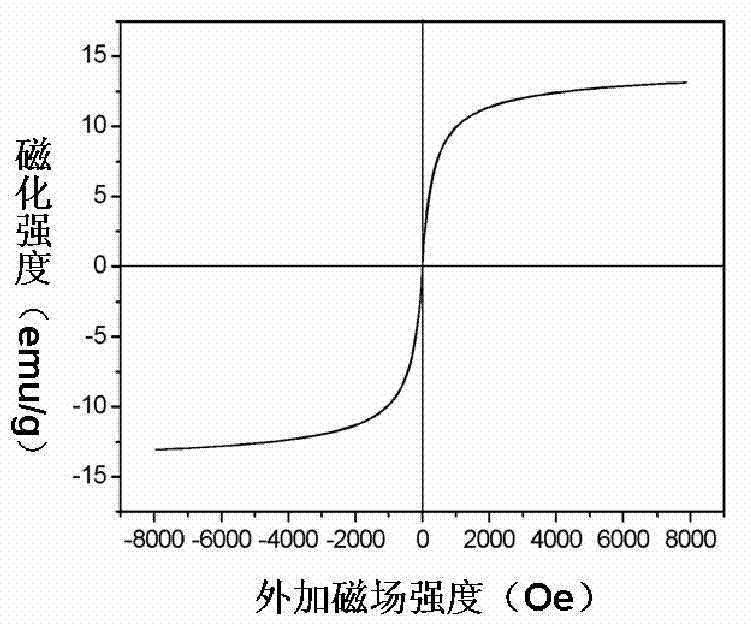

A hollow microsphere, dual-function technology, applied in the direction of microsphere preparation, chemical instruments and methods, microcapsule preparation, etc., can solve the problems of low saturation magnetization of microspheres, poor magnetic responsiveness, and limited biomedical applications, etc. Achieve the effects of narrow particle size distribution, stable fluorescence characteristics, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

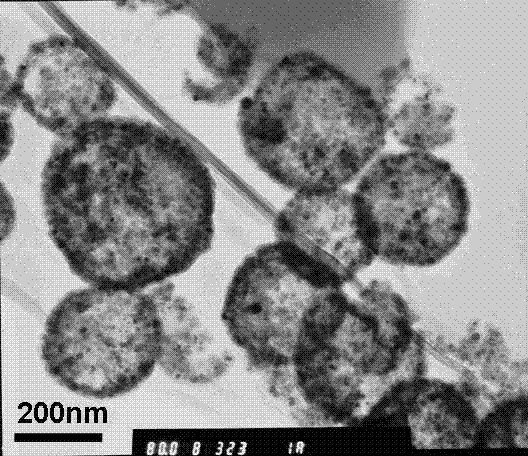

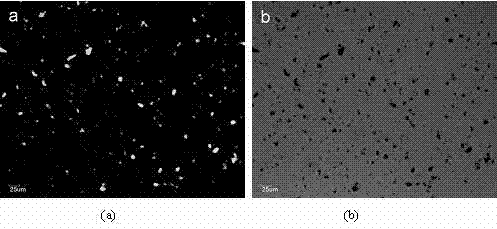

[0028] Example 1. 24 g FeCl 3 ·6H 2 O and 9.82 g FeCl 2 ·7H 2 Dissolve O in an appropriate amount of water, add an appropriate amount of ammonia water, pass N 2 Gas, heated at 80°C for 30min, then added 3.76 g of oleic acid, continued to heat and stir for 1h, then stopped passing through N 2 , volatilize ammonia water until a large amount of black precipitate appears after stopping stirring, then the reaction can be stopped. Under magnetic separation, the precipitate is washed with deionized water to neutrality, and then washed with deionized water and ethanol three times respectively, and the obtained magnetic Particles, ultrasonically disperse the magnetic particles in an appropriate amount of n-octane, and then evaporate the n-octane to dryness by rotary evaporation, and set aside; dissolve 0.092 g SDS in 40 g deionized water, dissolve 8 g styrene monomer, 0.4 g hexadecane , 1 g TEOS, and 55 mg magnetic particle dispersion were mixed and ultrasonicated to form a uni...

Embodiment 2

[0029] Example 2. 24 g FeCl 3 ·6H 2 O and 9.82 g FeCl 2 ·7H 2 Dissolve O in an appropriate amount of water, add an appropriate amount of ammonia water, pass N 2 Gas, heated at 80°C for 30min, then added 3.76 g of oleic acid, continued to heat and stir for 1h, then stopped passing through N 2 , volatilize ammonia water until a large amount of black precipitate appears after stopping stirring, then the reaction can be stopped. Under magnetic separation, the precipitate is washed with deionized water to neutrality, and then washed with deionized water and ethanol three times respectively, and the obtained magnetic Particles, ultrasonically disperse the magnetic particles in an appropriate amount of n-octane, then evaporate the n-octane to dryness by rotary evaporation, and set aside; dissolve 0.12 g SDBS in 40 g deionized water, mix 8 g styrene monomer, 0.4 g hexadecane , 2 g of methyl orthosilicate, and 80 mg of magnetic particle dispersion were mixed and ultrasonicated ...

Embodiment 3

[0030] Example 3. 24 g FeCl 3 ·6H 2 O and 9.82 g FeCl 2 ·7H 2 Dissolve O in an appropriate amount of water, add an appropriate amount of ammonia water, pass N 2 Gas, heated at 80°C for 30min, then added 3.76 g of oleic acid, continued to heat and stir for 1h, then stopped passing through N 2 , volatilize ammonia water until a large amount of black precipitate appears after stopping stirring, then the reaction can be stopped. Under magnetic separation, the precipitate is washed with deionized water to neutrality, and then washed with deionized water and ethanol three times respectively, and the obtained magnetic Particles, ultrasonically disperse the magnetic particles in an appropriate amount of n-octane, then evaporate the n-octane to dryness by rotary evaporation, and set aside; dissolve 0.23 g of SDS in 40 g of deionized water, mix 8 g of styrene monomer, 0.4 g of cetyl alcohol , 1 g TEOS, and 55 mg magnetic particle dispersion were mixed and ultrasonicated to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com