Amphiphobic fluoro-containing crosslinkable block copolymer and preparation method and application thereof

A block copolymer, hydrophobic technology, applied in coatings, paper coatings, textiles and papermaking, etc., can solve problems such as connection, and achieve the effect of not easy to fall off and denature, and strong coating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

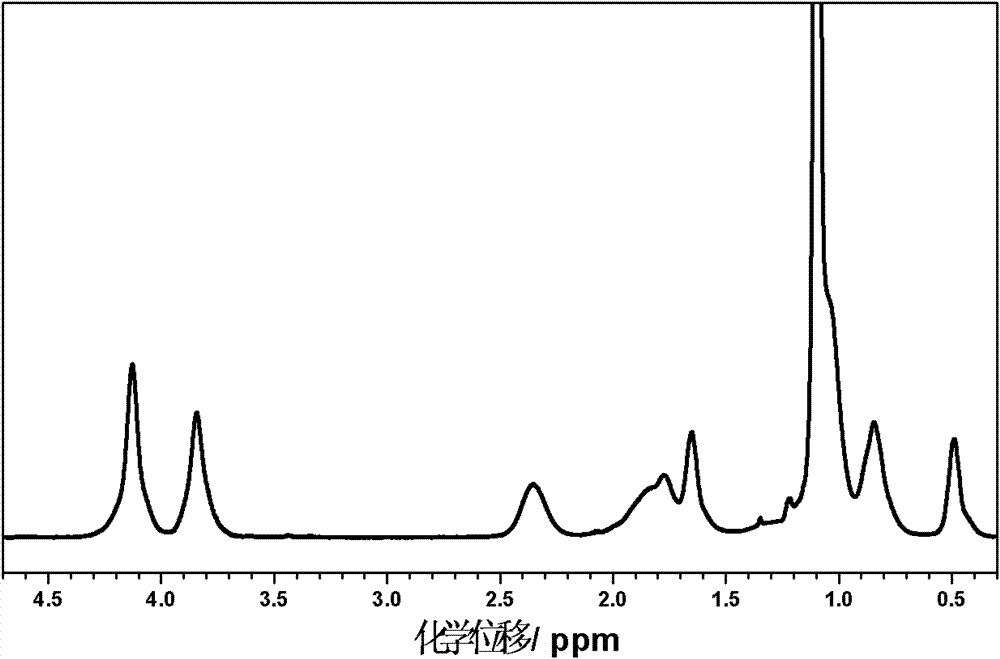

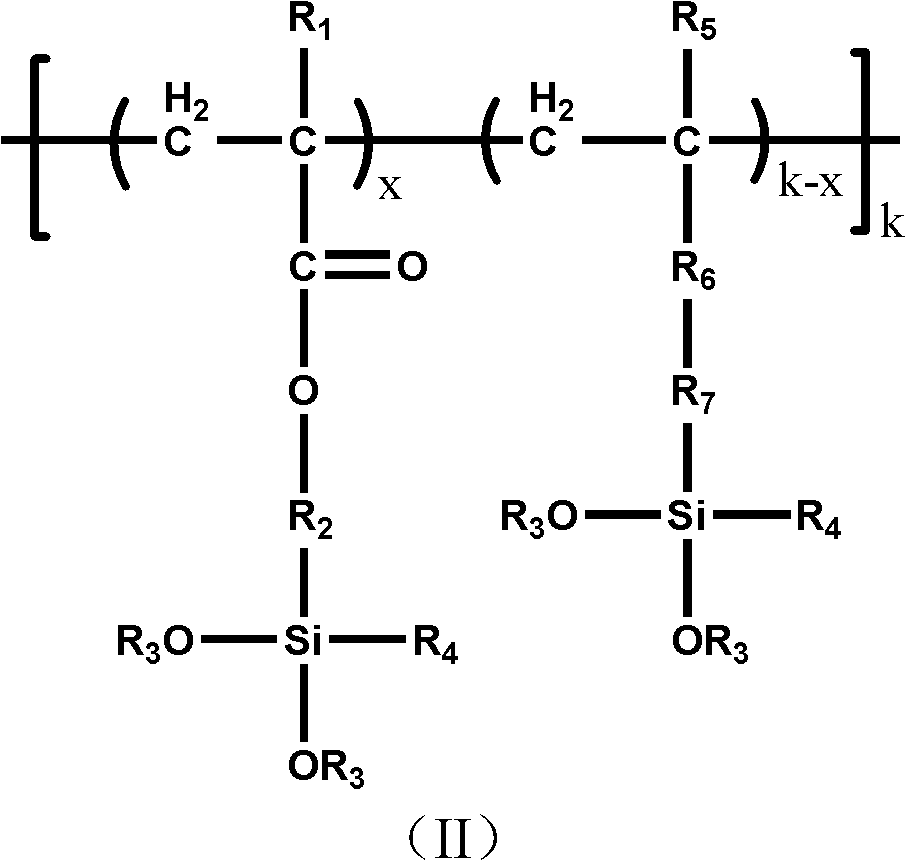

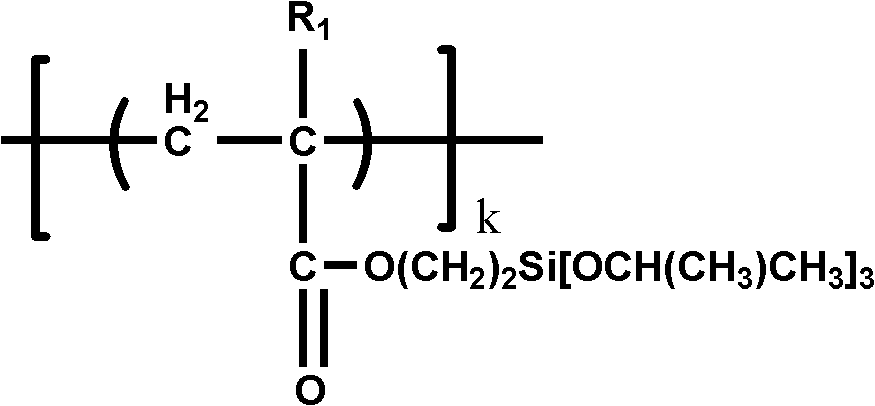

[0048] 1. Preparation of amphiphobic fluorine-containing crosslinkable block copolymers

[0049] The materials used below are from:

[0050] IPSMA was prepared by the method reported in literature (Ozaki, H.; Hirao, A.; Nakahama, S. Macromolecules 1992, 25:1391-1395.);

[0051] f 8 h 2 MA was purchased from Aldrich Company, and the reference (Ishizone, T.; Sugiyama, K.; Sakano, Y.; Mori, H.; Hirao, A.; Nakahama, S. Polymer Journal 1999, 31: 983- 988.) The reported method is purification by distillation under reduced pressure;

[0052] The preparation steps of amphiphobic fluorine-containing crosslinkable block copolymer are as follows:

[0053] At -78°C (dry ice acetone bath), 0.19 ml (1.09 mmol) of 1,1-diphenylethylene was added to a three-necked flask containing 250 ml of anhydrous tetrahydrofuran, followed by 0.6 ml of 1.4 mol / L para Butyllithium in hexane. After 15 minutes, 2.59 ml (7.3 mmol) of IPSMA were added, and after 2 hours of polymerization, 2.60 ml (7.8 mmol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com