Fluorine-containing bi-functional microspheres and application thereof

A functional, microsphere technology, used in coatings, special surfaces, devices for coating liquids on surfaces, etc., can solve problems such as no one reported, and achieve the advantages of not easy to fall off and deformation, accurate performance parameters, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

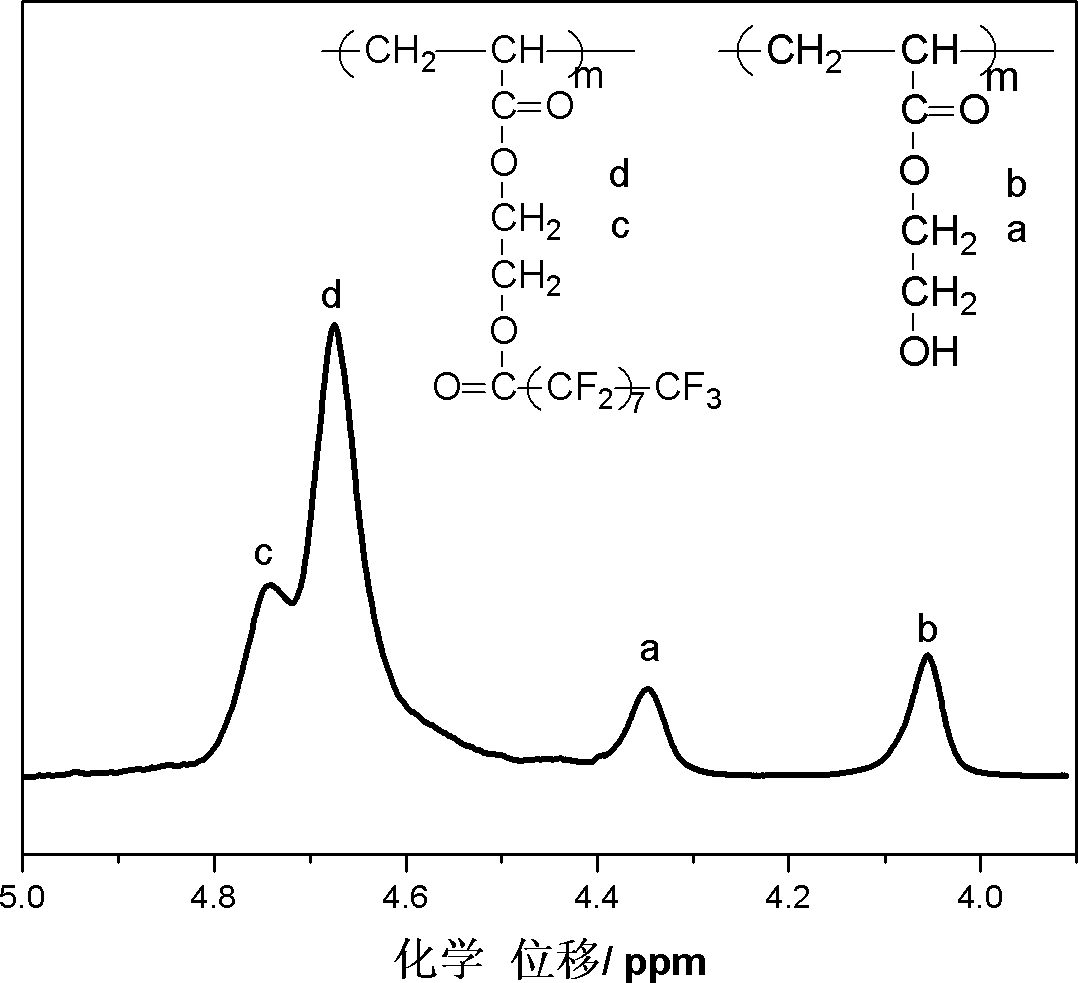

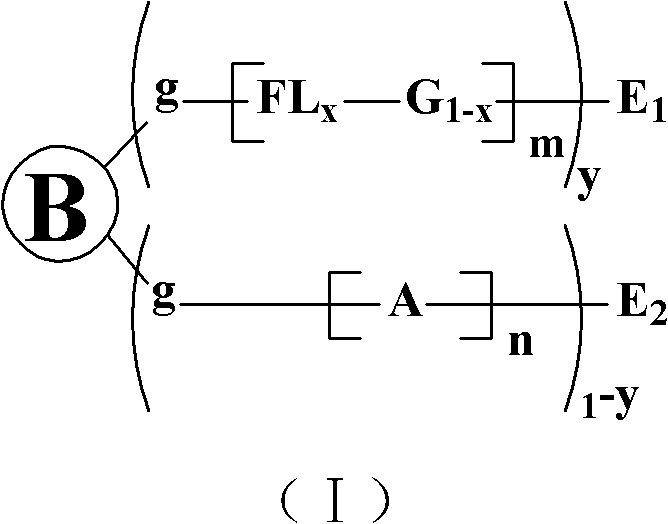

[0052] 1. Preparation of fluorine-containing bifunctional polymer microspheres

[0053] The materials used below are from:

[0054] Monomers hydroxyethylene acrylate (HEA), methyl methacrylate (MMA) and ethylene glycol dimethacrylate (EGDMA) were purchased from Aldrich and purified by vacuum distillation before use. Monomer acrylic acid, ethylene glycol diester 2-chloropropionate was reported by literature (Ming, W.; Wu, D.; van Benthem, R.; de With, G. Nano Lett. 2005, 5: 2298-2301) method of preparation. Azobisisobutyronitrile (AIBN) was purchased from Fisher Corporation and purified by recrystallization in ethanol before use. Others were actually purchased from Aldrich Company, without special treatment before use.

[0055] The preparation steps of fluorine-containing bifunctional polymer microspheres are as follows:

[0056] Under stirring, in the there-necked flask of 500 milliliters, gradually add the mixture of 130 milliliters of distilled waters, 4.80 grams (48.0 m...

Embodiment 2

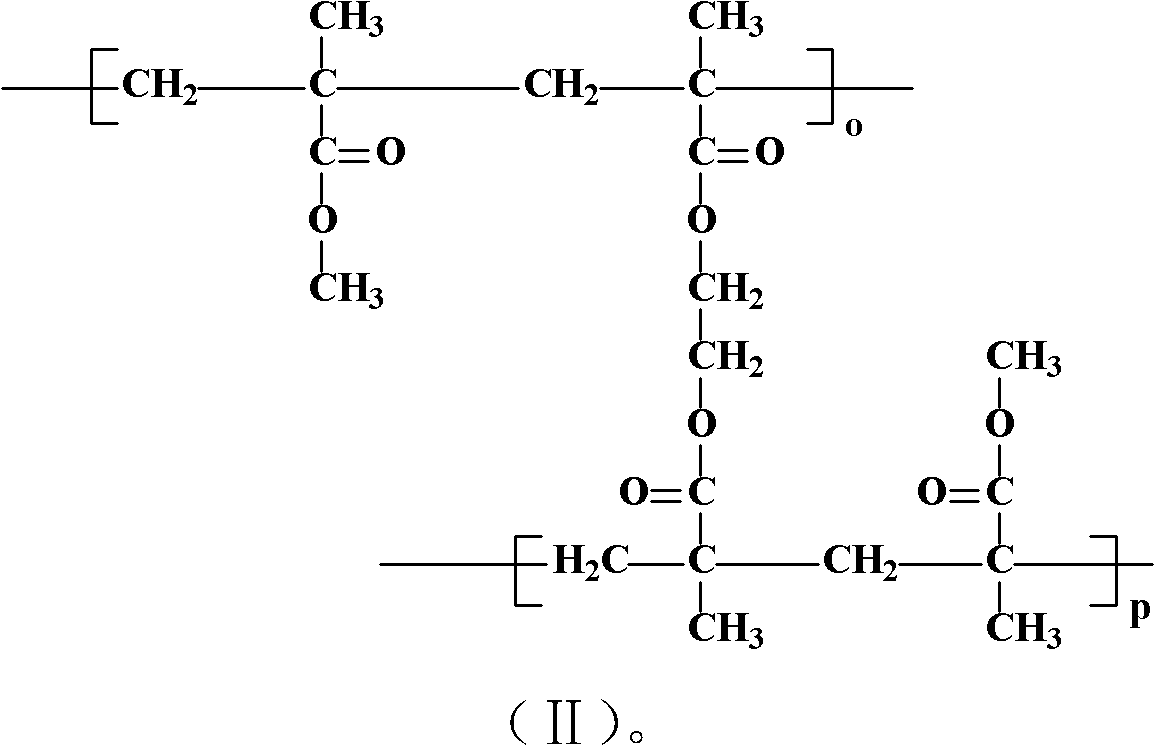

[0069] 1. Preparation of block copolymers

[0070] The materials used below are from:

[0071] (3-(triisopropoxysilyl))propylene methacrylate (IPSMA) was reported by literature (Ozaki, H.; Hirao, A.; Nakahama, S. Macromolecules 1992, 25:1391-1395.) prepared by the method;

[0072] (Heptadecafluorooctyl)ethylene methacrylate (F 8 h 2 MA) was purchased from Aldrich Company, and the literature (Ishizone, T.; Sugiyama, K.; Sakano, Y.; Mori, H.; Hirao, A.; Nakahama, S. Polymer Journal 1999, 31: 983 -988.) report method vacuum distillation purification;

[0073] Tert-butyl acrylate (tBA) is purchased from Aldrich Company, and is purified by underpressure distillation before use;

[0074] The preparation steps of fluorine-containing bifunctional silicon spheres are as follows:

[0075]Polymer poly(3-(triisopropoxysilyl))propylene methacrylate-block-poly(heptadecafluorooctyl)ethylene methacrylate (PIPSMA-b-PF8H 2 MA) and poly(3-(triisopropoxysilyl))propylene methacrylate-block-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com